No-cutting and no-bonding cover turning carton and folding method thereof

A folding method and flip-top technology, applied in rigid containers, containers, packaging, etc., can solve the problems of poor environmental protection performance, complex processing technology and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

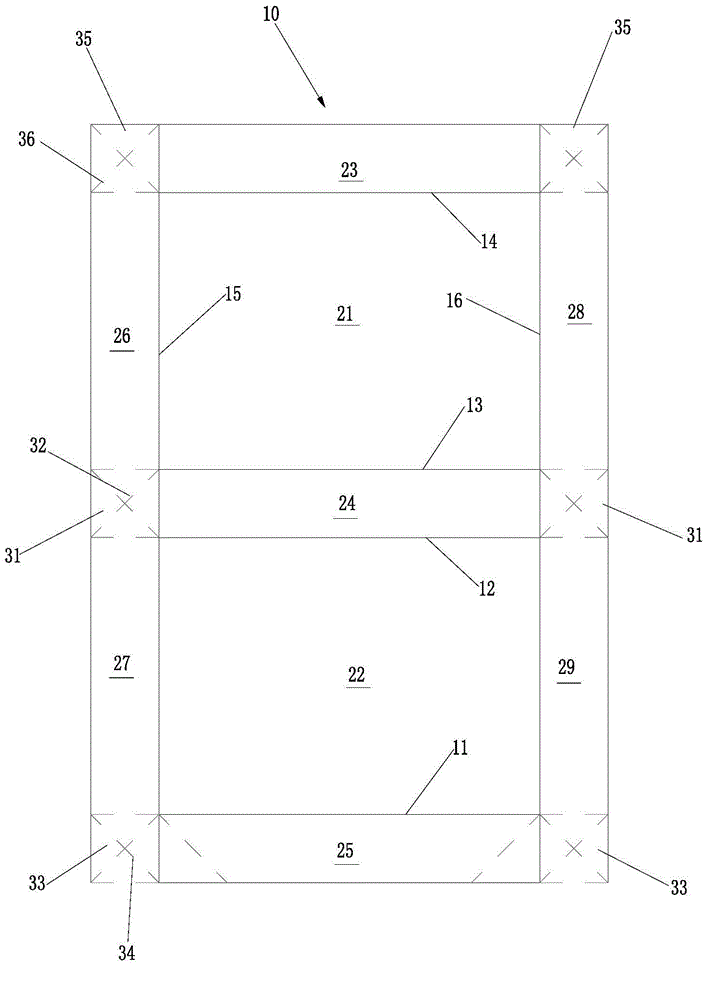

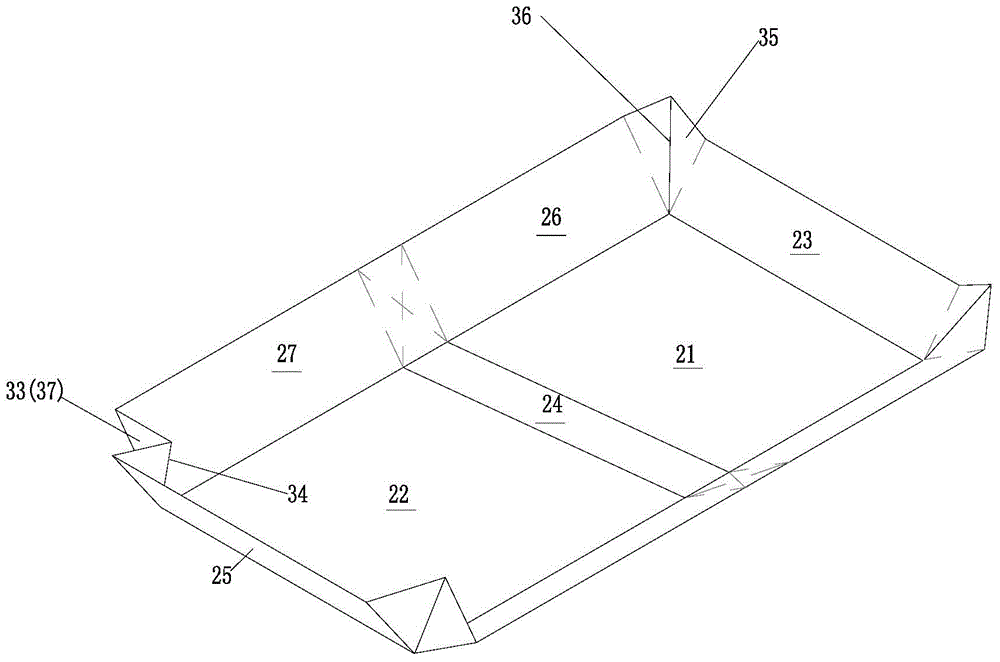

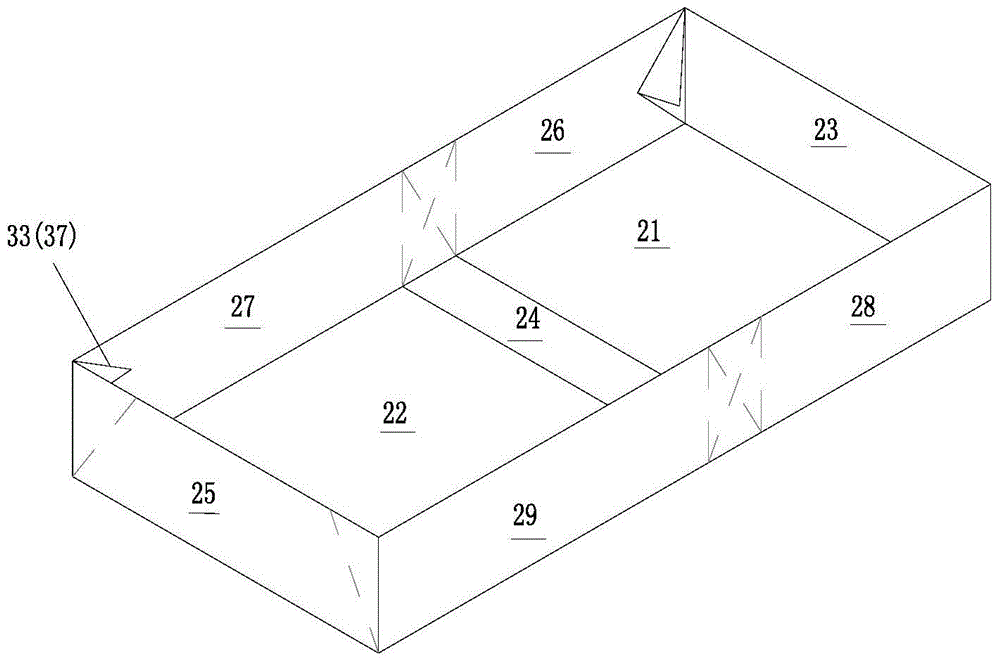

[0036] Please check Figure 1 to Figure 6 , a flip-top carton without cutting and pasting, including a foldable cardboard 10, such as double-sided coated paper or kraft paper, which can be made of about 200 grams to 350 grams of paper, and the cardboard 10 has a rectangular structure. Preferably, the paperboard 10 is printed with an instructional layer. The following up and down are not limited to the actual use of the up and down, but are only defined for the convenience of describing the overall structure.

[0037] The cardboard 10 is provided with four horizontal creases 11, 12, 13, 14 parallel to the front and rear and two vertical creases 15, 16 parallel to the left and right; , the longitudinal creases 15, 16 are parallel to the left and right sides of the cardboard 10. The four horizontal creases 11, 12, 13, 14 are respectively the first horizontal crease 11, the second horizontal crease 12, the third horizontal crease 13, and the fourth horizontal crease 14 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com