Reverse osmosis water purification machine system for automatically adjusting recovery rate and control method thereof

A technology of automatic adjustment and recovery rate, applied in water treatment parameter control, permeation/dialysis water/sewage treatment, chemical instruments and methods, etc., can solve problems such as no water saving method, reduced service life, and pollutant blockage, etc., to achieve The effects of avoiding waste of water resources, improving technical level, and saving flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The embodiments are not intended to limit the scope of protection of the invention. Obviously, those skilled in the art can obtain other embodiments without having to pay creative work. Belong to the protection scope of the present invention.

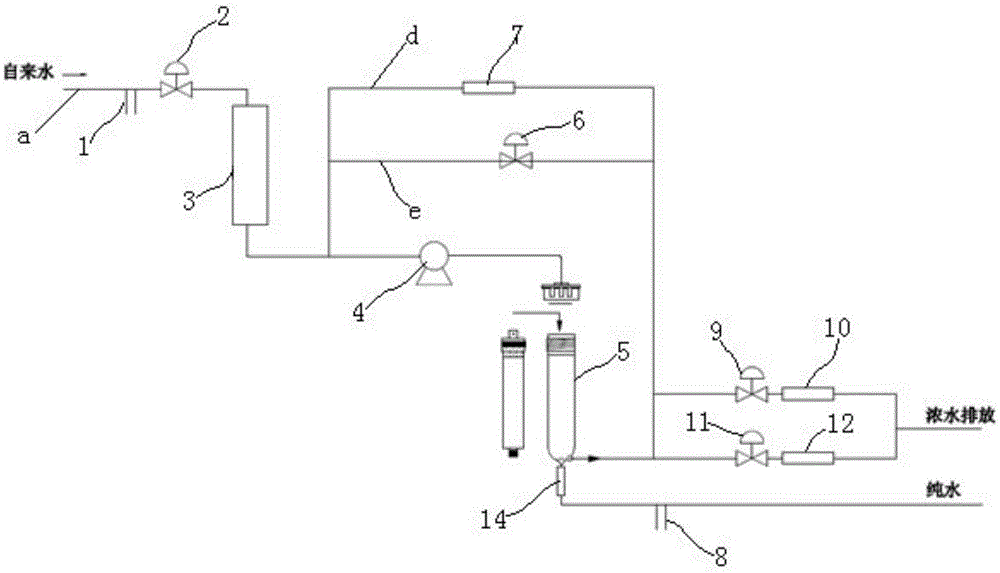

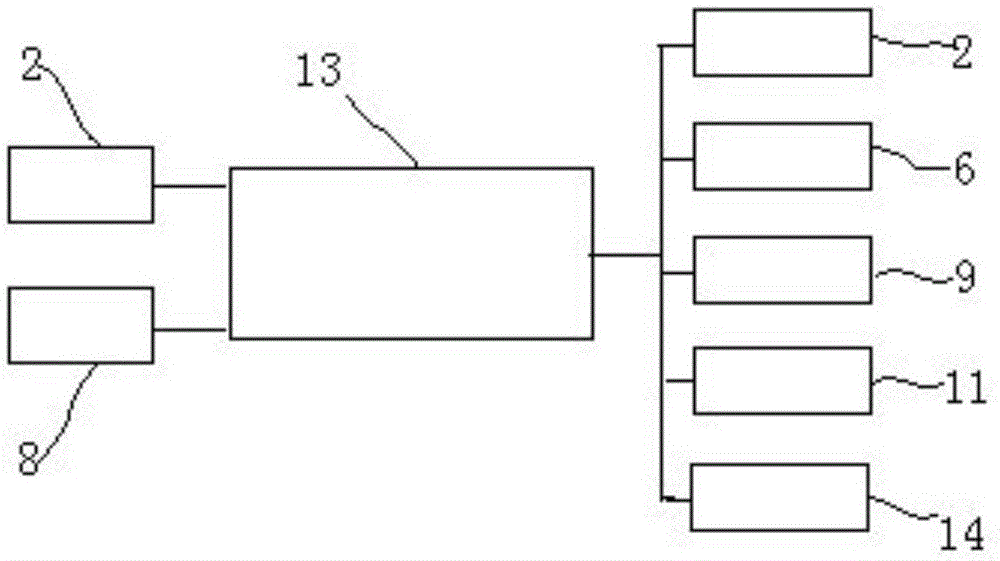

[0028] combine figure 1 As shown, a reverse osmosis pure water machine system that automatically adjusts the recovery rate, which includes the first TDS probe 1 installed on the pipeline a, the water inlet solenoid valve 2, the pre-filter system 3, and the booster pump 4 , RO membrane 5, the external water source of the pipeline is tap water. The pipeline connected to the concentrated water outlet of the RO membrane includes two parallel pipelines b, c, in which a first solenoid valve 11 and a first waste water ratio 12 are sequentially installed on one pipeline, and a second electromagnetic valve is seq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com