Ceramic membrane with capillary structure and super dehumidifying and wetting performance and preparation method thereof

A capillary structure, ceramic membrane technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as hydrophilic surfaces that have not yet been seen, and achieve the effects of good thermal conductivity and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

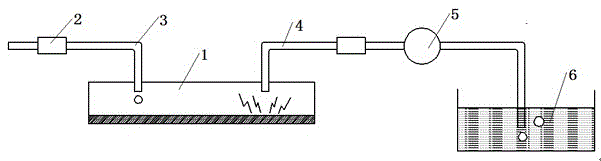

Method used

Image

Examples

Embodiment Construction

[0038]In the present invention, in addition to preparing ceramic films on aluminum (or aluminum alloy) planar substrates in the shape of foils, sheets, plates, etc., ceramic films can also be prepared on non-planar structures such as aluminum (or aluminum alloy) wires. Membranes are used in various occasions. There is no particular limitation on the shape of the base.

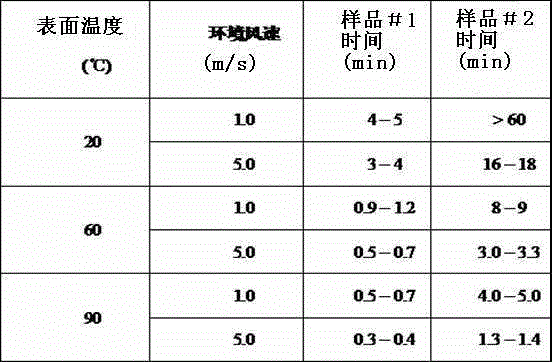

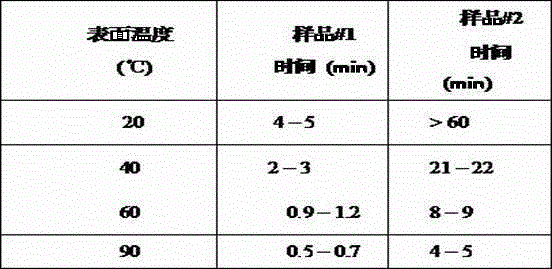

[0039] Due to the super wetting function of the ceramic membrane, the contact area between water droplets and air is as high as 300-1333cm when water droplets form on the ceramic membrane. 2 / g, that is, the heat exchange area between the water film and the ceramic film and air is large, so the water film can easily absorb heat from the environment and evaporate, changing from liquid to gas. At the same time, because the thickness of the water film is very thin (the thinnest can reach 7.5 μm / g), the temperature gradient in the thickness direction is small, which is conducive to the rapid heat absorption and ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com