Large-scale complex curved surface measurement system and application thereof

A measurement system and technology for complex surfaces, applied in the field of large-scale complex surface measurement systems, can solve problems such as complicated preprocessing of lattice data, difficulty in ensuring the accuracy and efficiency of reconstructed surfaces, and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

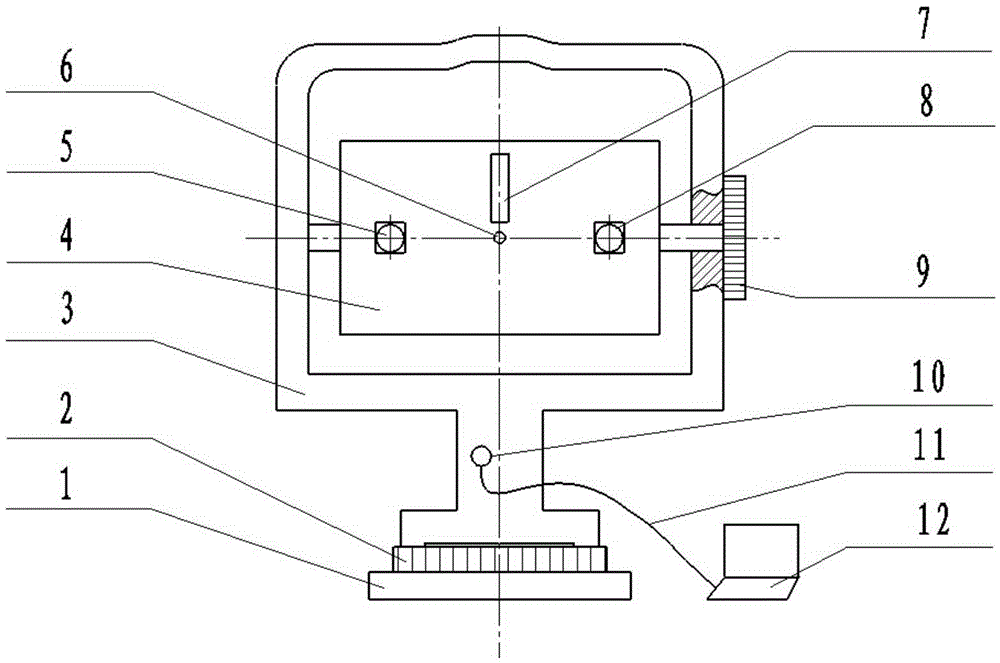

[0063] Such as figure 1 and figure 2As shown in , a large complex curved surface measurement system, the system is based on the two-way space forward intersection principle to achieve the acquisition of large complex curved surface three-dimensional lattice device. The measurement system includes a base 1, a horizontal indexing plate 2, a horizontal support 3, a pitching support 4, a camera 5 and a camera 8, a laser range finder 6, a line laser transmitter 7, a pitching indexing plate 9, a data line interface 10, Data line 11 and computer 12; Horizontal index plate 2 and horizontal support 3 are fixed together, and both are installed on the top of base 1; Camera 5 and camera 8, and laser range finder 6 and line laser emitter 7 are installed on pitching On the support 4; the pitch support 4 is installed on the horizontal support 3; the pitch index plate 9 is fixedly installed on the pitch support 4, on the right side of the horizontal support 3; the computer 12 that is respon...

Embodiment 2

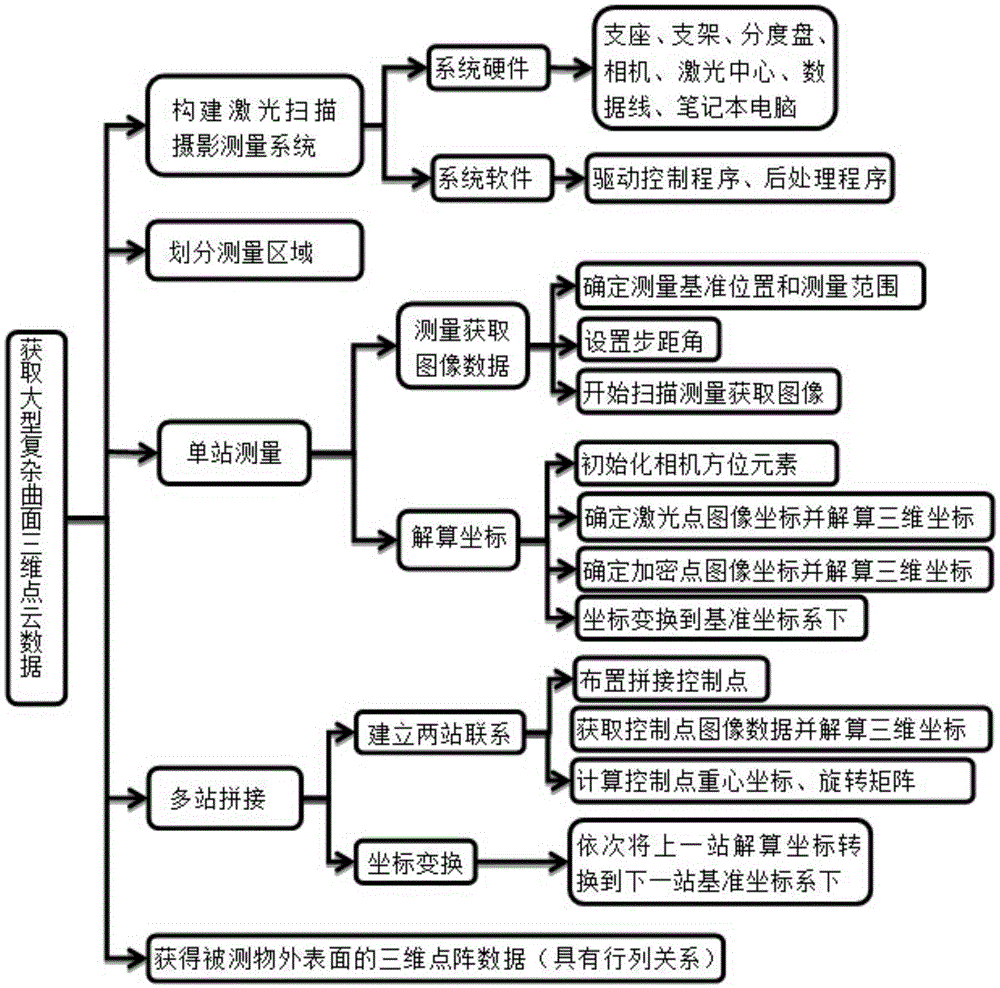

[0072] Based on the measurement system described in Embodiment 1, this embodiment elaborates in detail the method for measuring large complex curved surfaces using the measurement system described in Embodiment 1, the method is as follows:

[0073] 1. Data sampling and calculation of a single measurement area (the process of single-station measurement and calculation of the outer surface of the target object):

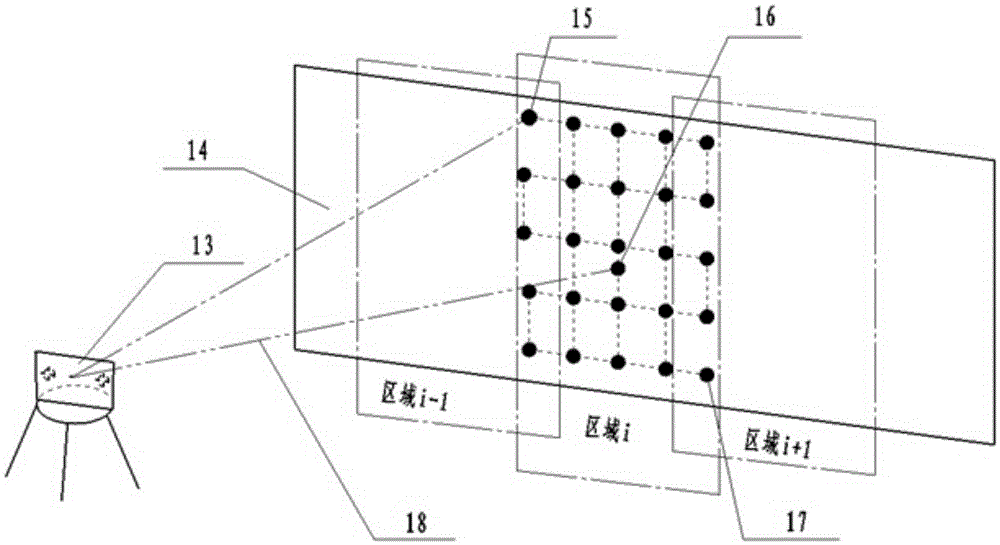

[0074] as attached image 3 As shown, the outer surface 14 of the measured object is divided into n regions, and the measurement system 13 is placed directly against a certain measurement region i. The point laser 18 emitted by the laser rangefinder is approximately perpendicular to the outer surface 14 of the measured object, and the vertical foot is Position point 16; position point 15 and position point 17 are the measurement start point and end point respectively. The single-station measurement is carried out by using the laser cycle scanning and camera capture to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com