Comprehensive weighted evaluation method of pump unit energy consumption

A weighted evaluation and pump device technology, applied in special data processing applications, complex mathematical operations, instruments, etc., can solve the problems of low loss rate of electromechanical equipment, short running time, unscientific basis, etc., and achieve the effect of saving energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

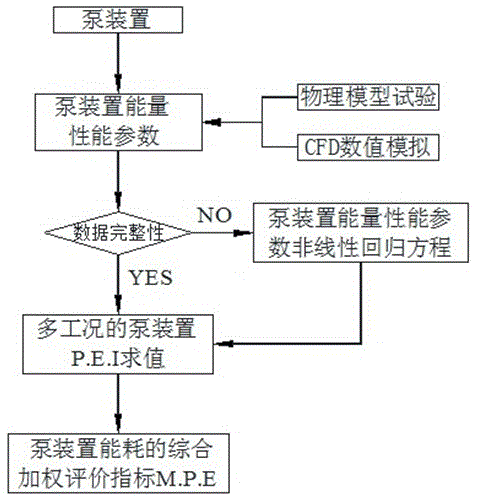

[0022] The energy consumption process of a pump device is as follows: figure 1 shown.

[0023] The energy performance data of four sets of pump devices are available, but they do not include all the operating point data. For this reason, the method of step 1) above is used to construct the numerical function relationship between Q·η and H. The mathematical equation is as follows:

[0024]

[0025] In the formula: y=Q·η, x=H.

[0026] The Gauss-Newton algorithm is used to solve the regression constant and partial regression coefficient of the nonlinear regression equation, and the solution results are shown in Table 1. The determination coefficients of each nonlinear regression equation are greater than 0.99, meeting the requirements.

[0027] Table 1 Coefficients of nonlinear regression mathematical equation

[0028]

[0029] On the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com