SiC@SiO2 coaxial nanocable and preparation method thereof

A nano-cable and coaxial technology, applied in the field of one-dimensional nano-materials and their preparation, can solve the problems of easy oxidation on the surface of SiC nano-fibers, damage to the surface morphology and structure, and difficulty in controlling the product structure, and achieve excellent uniformity, Easy-to-control, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

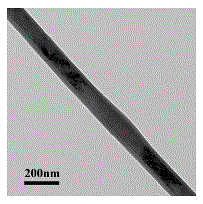

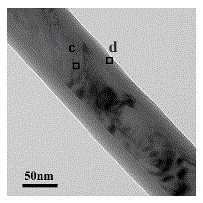

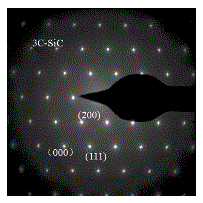

[0022] Specific implementation mode 1: This implementation mode provides a SiCSiO 2 Coaxial nanocable, which is a kind of "core part is 3C-SiC, outer layer is amorphous SiO 2 "One-dimensional nanomaterials with core-shell structure, SiO 2 Tightly clad outside the SiC of the core, where the bonding at the interface is a tight bonding at the atomic scale. SiCSiO 2 The length of the coaxial nano-cable can reach the order of centimeters, and the diameter can be controlled at 10-1000nm, in which the diameter of the core SiC is 2-1000nm, and the outer shell SiO 2 The layer thickness is 1-500nm.

[0023] Depend on figure 1 It can be seen that a typical SiCSiO 2 The core of the coaxial nanocable is surrounded by SiC nanofibers and an outer uniform cladding layer. Figure 2-4 It can be seen that the core is cubic phase 3C-SiC, and the outer cladding layer is an amorphous layer; Figure 5 It can be seen that the dynamic oxidation process of SiC nanofibers is controlled by thermal...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that SiCSiO 2 The length of the coaxial nano-cable can be controlled within 10um~12cm, the diameter is 10~1000nm, the diameter of the core SiC is 2~1000nm, and the outer shell SiO 2 The layer thickness is 1-500nm.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiments one and two is that a single SiCSiO 2 The length of the coaxial nano-cable reaches 5-40mm, and the diameter is 100-200nm, in which the core SiC diameter is 2-198nm, and the shell SiO 2 The layer thickness is 2-99nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com