Composite amorphous transformer core

A transformer core, composite technology, applied in the direction of transformer/inductor core, magnetic materials, magnetic objects, etc., can solve the problem that amorphous transformers do not have vitality and market competitiveness, rectangular windings are unevenly stressed, and amorphous Transformer promotion restrictions and other issues, to achieve the effect of improving effective utilization, improving short-circuit resistance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with specific production processes. Obviously, the described embodiments are part of the implementation of the present invention example, not all examples. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

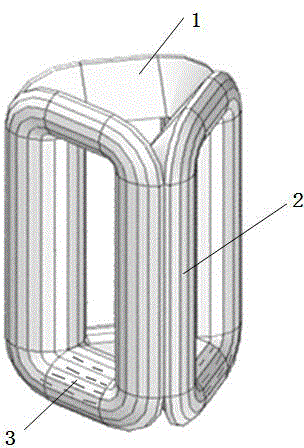

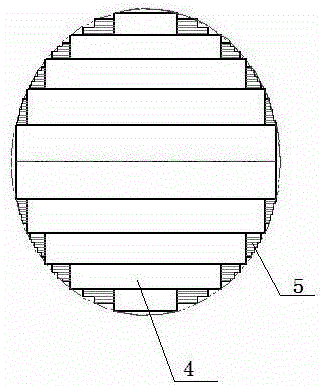

[0024] A composite amorphous transformer iron core is provided with three separate rectangular iron core frames, the iron core frames are composed of two materials in a stacked winding manner, and the three rectangular iron cores are butted to form a three-dimensional triangular structure. The core post 2 section of the assembled integral iron core is circular, ...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the amorphous alloy strip in this embodiment adopts six width specifications of 100mm, 130mm, 150mm, 170mm, 200mm, and 220mm.

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 is that the amorphous alloy strip of this embodiment adopts seven width specifications of 150mm, 180mm, 200mm, 230mm, 260mm, 280mm, and 300mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com