Square solid-state capacitor and fabrication method thereof

A capacitor, square technology, applied in the field of capacitors, can solve the problems of large ESR, poor temperature-frequency characteristics, failure of working electrolyte, etc., to achieve strong ripple resistance, not easy to break, equivalent series internal resistance and small impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

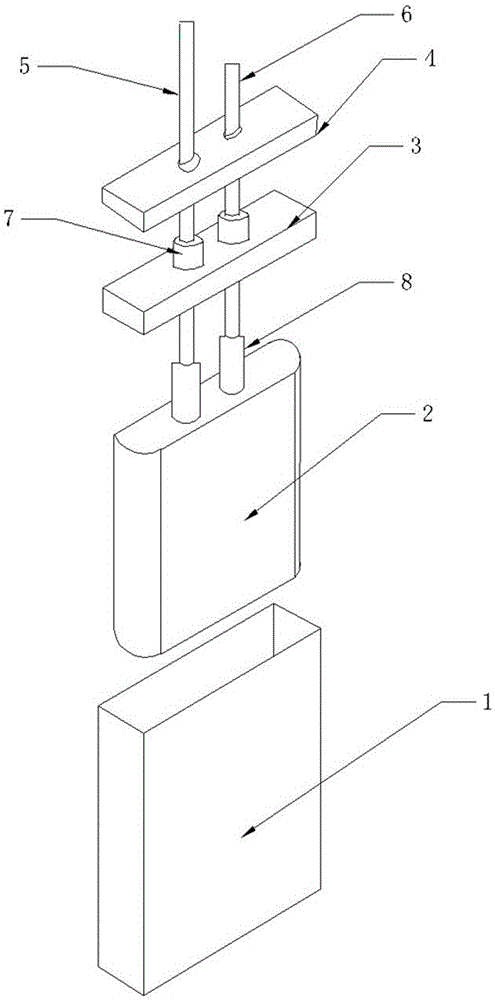

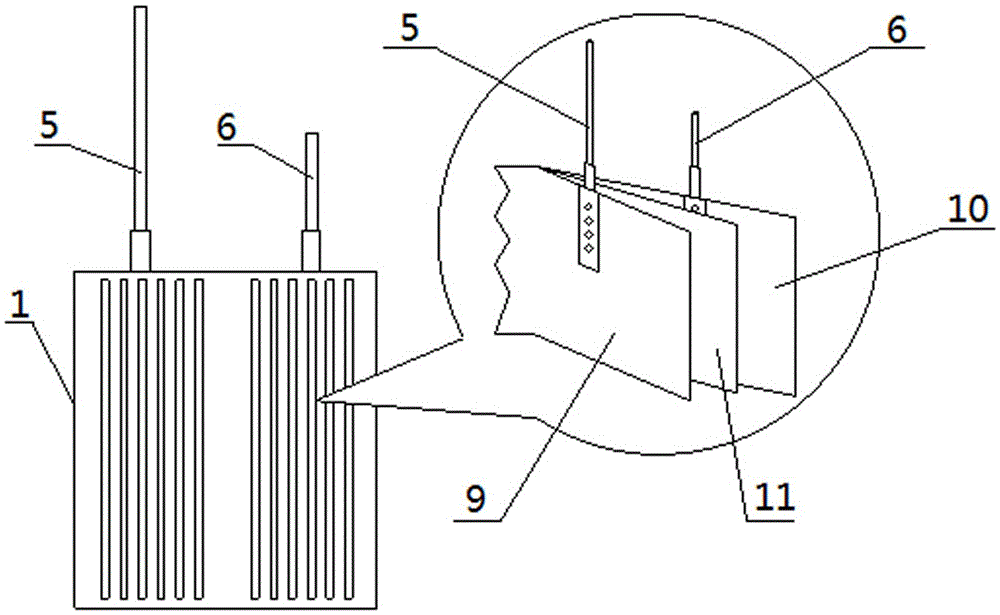

[0038] Such as figure 1 with figure 2 A square solid capacitor shown includes a square aluminum shell 1, a flat oval capacitor core pack 2, a rubber plug 3 and an aluminum shell cover plate 4; the rubber plug 3 and the aluminum shell cover plate 4 seal the core pack 2 in the Inside the square aluminum shell 1; the capacitor core package 2 includes an anode foil 9, a cathode foil 10, an electrolytic paper 11 between the anode foil 9 and the cathode foil 10, a positive electrode lead 5 and a negative electrode lead 6, and the electrolytic paper 11 is impregnated with a monomer and oxidant, and the monomer and oxidant generate a conductive polymer on the electrolytic paper, the monomer is one or more of EDOT (3,4-ethylenedioxythiophene) and its derivatives, pyrrole, aniline, and the oxidant is One or more of iron p-toluenesulfate, ammonium persulfate, sodium persulfate, ammonium sulfate, and ferric chloride; the positive electrode lead 5 and the negative electrode lead 6 are co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com