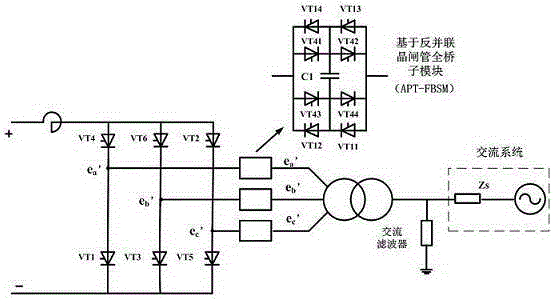

Line commutated converter structure for anti-parallel thyristor-based full bridge submodule converter

A power grid commutation, full-bridge sub-module technology, applied in the field of power transmission and distribution, can solve problems such as higher requirements for filter device following characteristics, loss of self-recovery capability of converters, long fault recovery time, etc. The effect of phase success, increasing commutation area, and improving power transmission capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

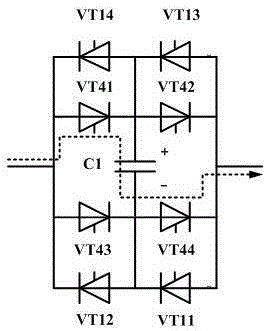

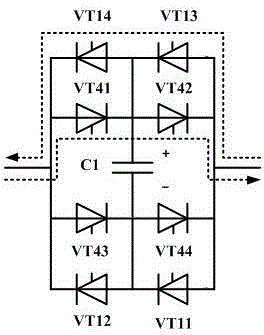

[0031] The invention provides a power grid commutation converter structure based on anti-parallel thyristor full-bridge sub-modules. The topology is that an APT-FBSM is connected in series between the converter and each phase of the converter transformer. The APT-FBSM is composed of four groups of thyristors in anti-parallel connection and a capacitor; each group of thyristors in the four groups of thyristors is composed of two thyristors in anti-parallel connection.

[0032] The APT-FBSM has three working states:

[0033] (1) When the AC system is running normally, when the capacitor voltage is lower than the initial given value and the valve arm is in the opening process (the valve arm is in the process of turning off and conducting), precharge the APT-FBSM connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com