Radial shaft seal

A technology for radial shaft seals and rotating shafts, which is applied to the sealing of engines, components of pumping devices for elastic fluids, non-variable pumps, etc., and can solve problems such as negative pressure and no air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

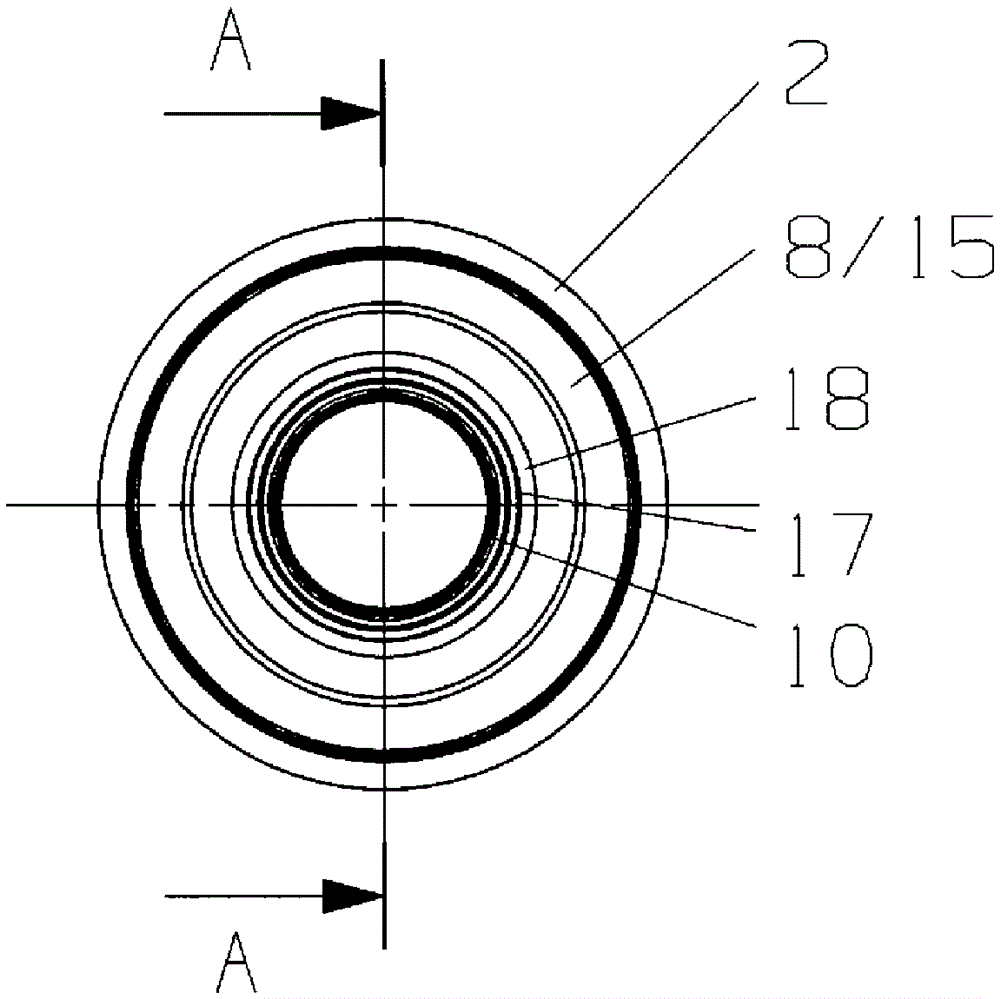

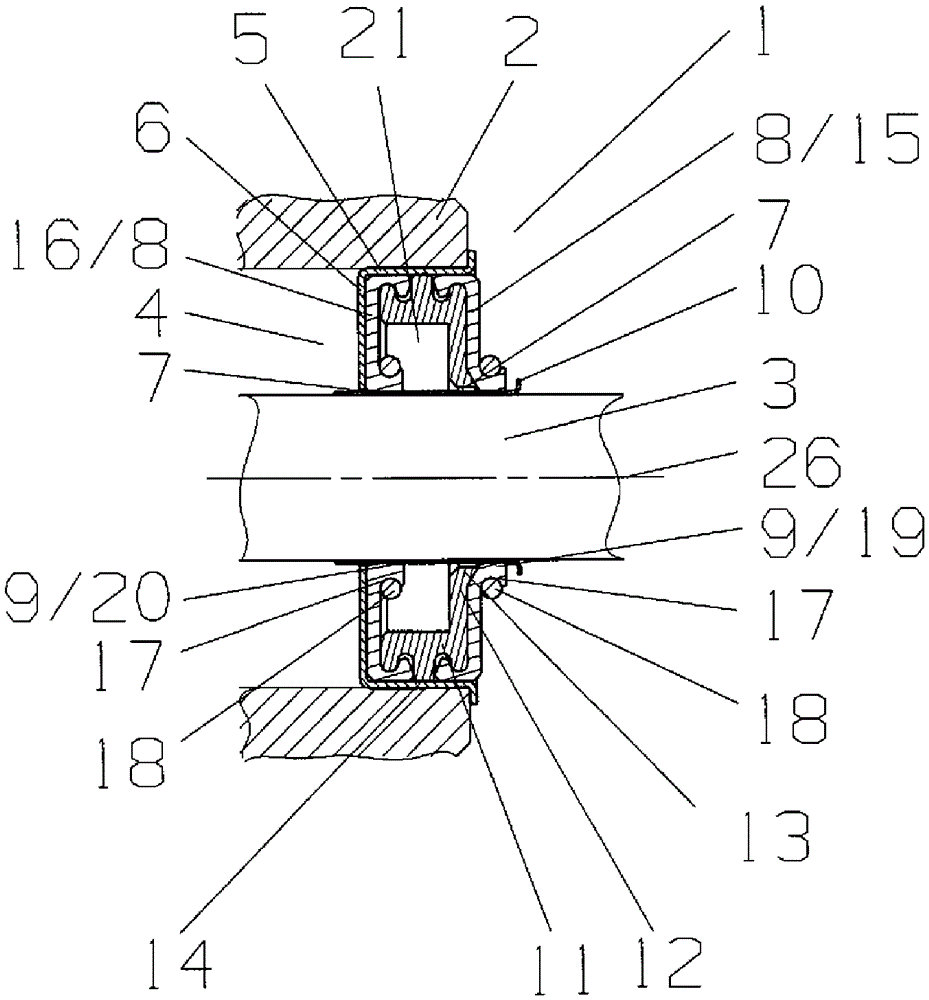

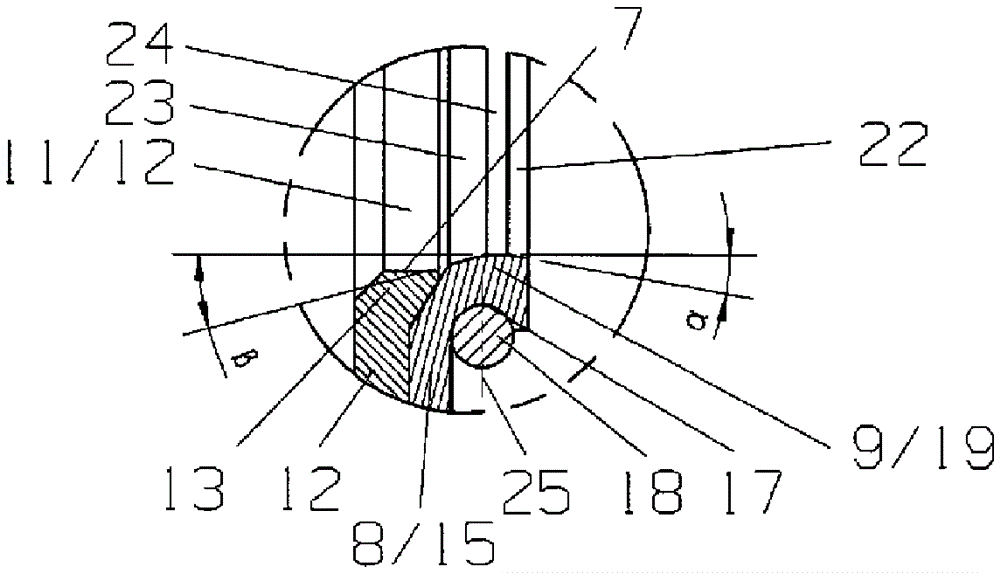

[0031] in figure 1 Shows the installed state of the radial shaft seal in the coolant pump according to the present invention, that is, after the final assembly.

[0032] This one figure 1 A radial shaft seal according to the present invention is shown for sealing the rotating shaft 3 leading from the pressure chamber 1 of the working housing 2 filled with a fluid medium with respect to the outer chamber 4, such as the atmosphere. A metal sealing housing 5 with a rear wall 6 is arranged in the hole of the working housing 2. The shaft through hole 7 is located inside this rear wall 6. Two ring-shaped sealing bodies 8 composed of elastic materials are arranged in the sealing shell 5, and the sealing lip 9 arranged on the sealing body 8 directly abuts against the rotating sleeve 10 arranged on the shaft 3 in an anti-rotation manner. The two sealing bodies 8 are simultaneously positioned in the sealing shell 5 by the annular metal support body 11.

[0033] What is important in the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com