Machine for harvesting root crop

A harvester and harvester technology, which is applied in the direction of digging harvester, harvester, application, etc., can solve the problems that affect the controllability of the system and the loss of harvest volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

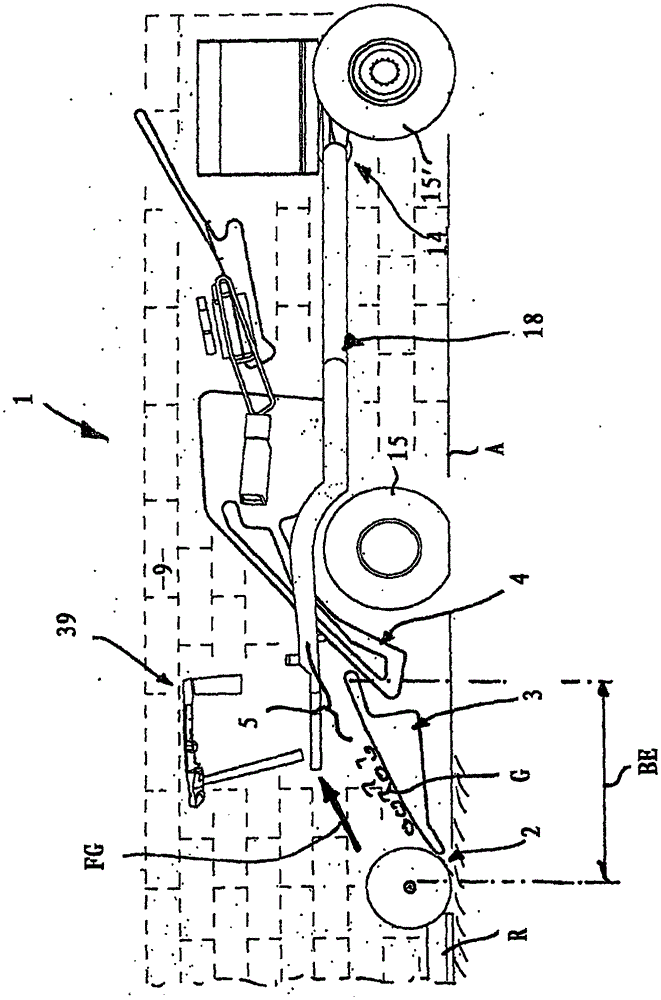

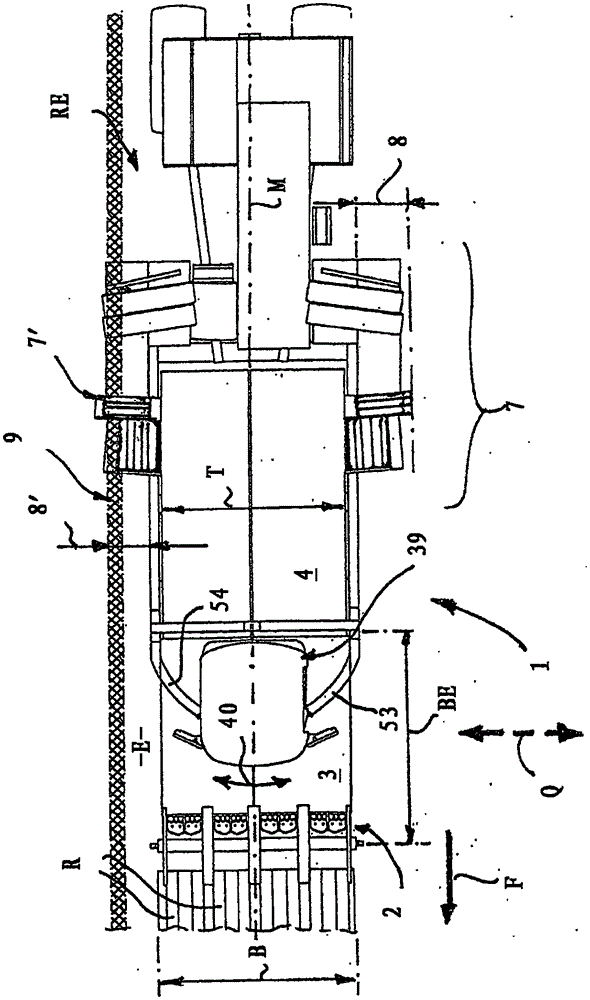

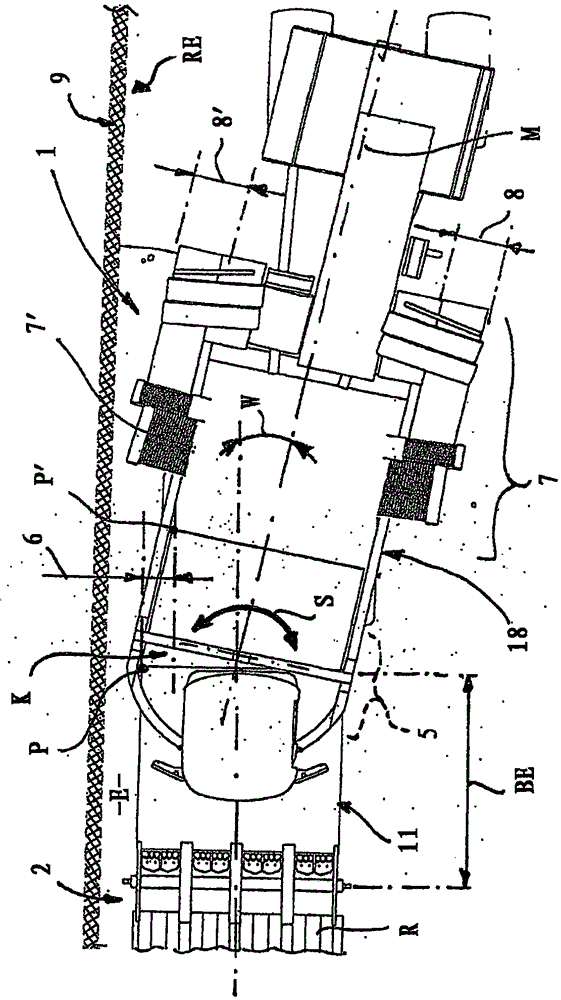

[0046] in such as Figure 1 to Figure 3 In the schematic diagram of , a machine for harvesting root crops, in particular in the form of a fully automatic potato harvester 1 , is shown in the form of a corresponding schematic diagram. From such as figure 1 As can be seen in the side view of , the structure has the excavating device 2 in the use position while using known components. Corresponding to the excavation width B, transversely to the direction of travel F, rows of harvest R containing mixed material from the cultivated field A are accommodated on the harvest field E.

[0047] In a self-propelled fully automatic potato harvester known from ( / ; 4), the two rows R are received by means of the digging device 2, and the harvested and mixed materials are loosened from the digging device The mixture G is then displaced by the first longitudinal conveyor belt 3 in the conveying direction FG counter to the direction of travel F. During this conveying phase, the conduction ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com