Radial ultra-fine water mist fire-extinguishing system for oil storage tank

A fire-extinguishing system and water mist technology, applied in fire rescue and other directions, can solve the problems of explosion, oil storage tank explosion, slow fire-extinguishing speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

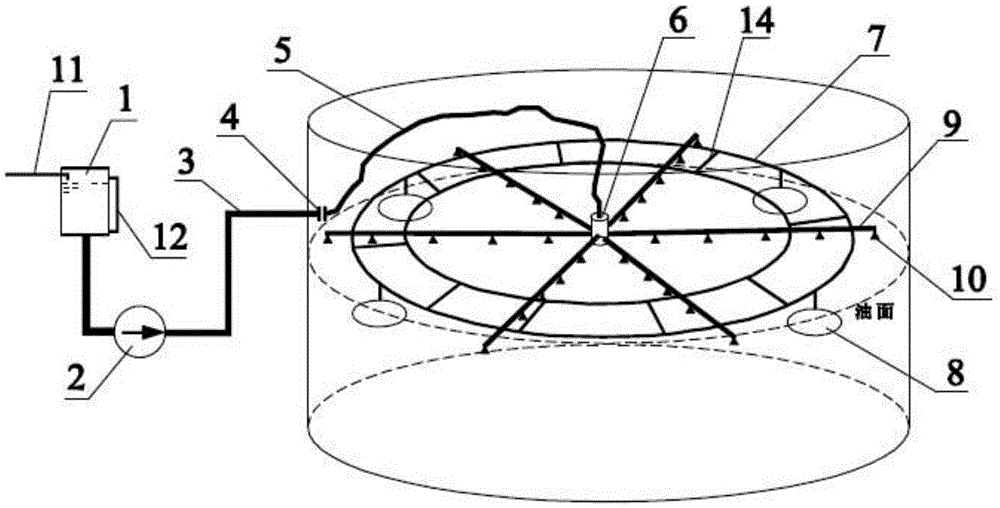

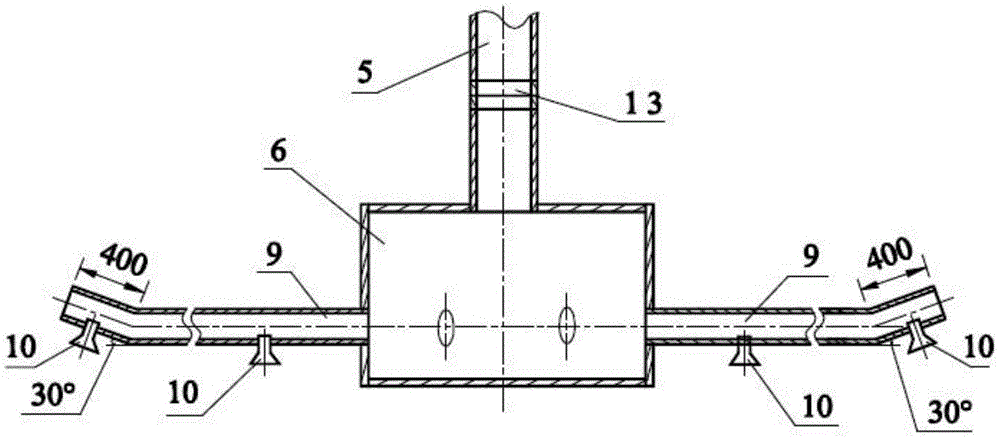

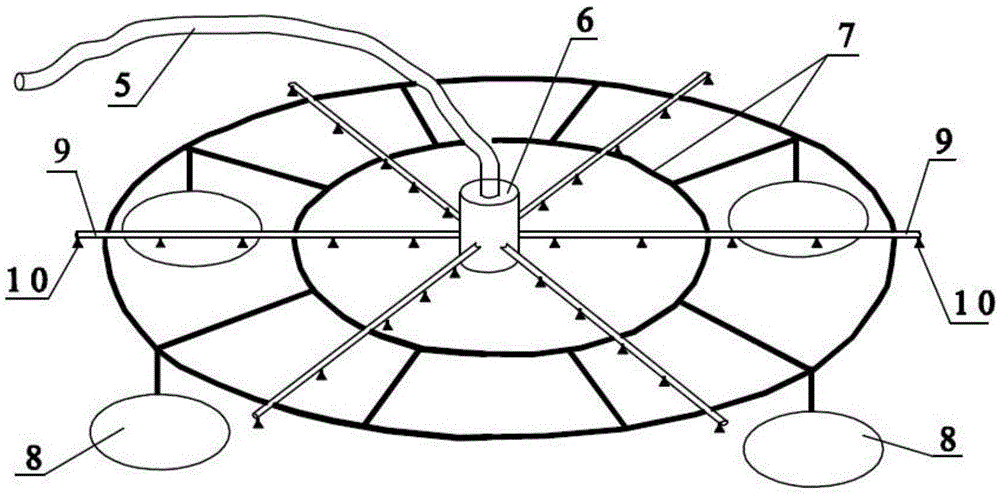

[0027] Embodiment: Referring to the accompanying drawings, the oil storage tank radial ultra-fine water mist fire extinguishing system of the present embodiment is provided with a metal bracket 7 suspended on the oil surface in the oil storage tank, and an ultra-fine water mist fire extinguishing system is fixedly installed on the metal bracket 7. A water mist injection device, the ultra-fine water mist injection device communicates with the high-pressure water supply device outside the oil storage tank through a pipeline;

[0028] Among them, the metal bracket 7 is composed of 2 to 3 aluminum alloy rings forming a concentric structure and reinforcing ribs 14 connected between the aluminum alloy rings, and a supporting floating ball 8 is provided at the bottom of the aluminum alloy rings / reinforcing ribs. The metal support 7 and the ultra-fine water mist spraying device are suspended on the oil surface.

[0029] The ultra-fine water mist spraying device is composed of a high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com