A kind of dialdehyde starch and preparation method thereof

A technology of dialdehyde starch and starch, which is applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problems of cumbersome and complicated reaction steps, long oxidation reaction time, and complicated post-treatment process , to achieve the effect of simple post-treatment process, improved reactivity, and reduced difficulty of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

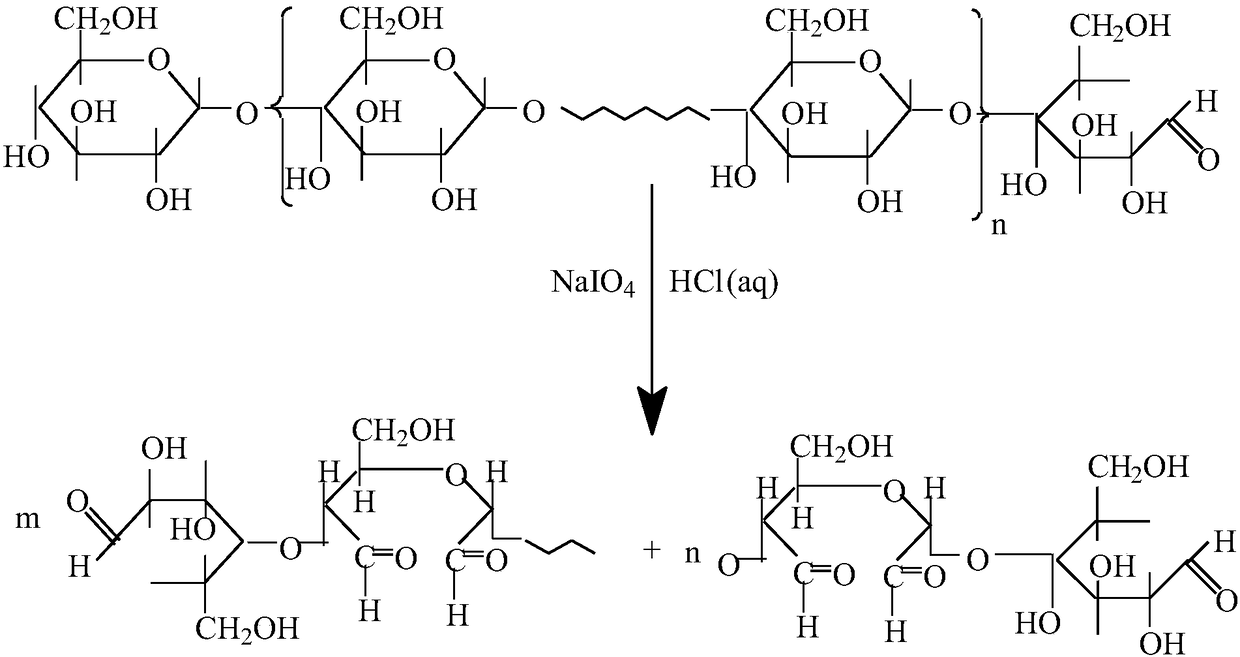

Method used

Image

Examples

Embodiment 1

[0027] A kind of embodiment of dialdehyde starch preparation method of the present invention, comprises the following steps:

[0028] (1) the sodium periodate of 150 weight parts and the hydrochloric acid of 15 weight parts 36.5wt% are dissolved in the deionized water of 650 weight parts, then add the corn starch of 162 weight parts, be made into corn starch mass fraction and be 16.6% starch milk.

[0029] (2) Transfer the starch milk obtained in step (1) to a reaction kettle with a stirrer, and perform acidolysis and oxidation reaction in a water bath at 30° C. for 5 hours. After the reaction, the obtained material is first washed with deionized water, and then pumped Filtrate until the pH of the filtrate is 7.0 (the material is neutral at this time), and then place it in an oven at 40° C. to dry to obtain the dialdehyde starch of the present invention.

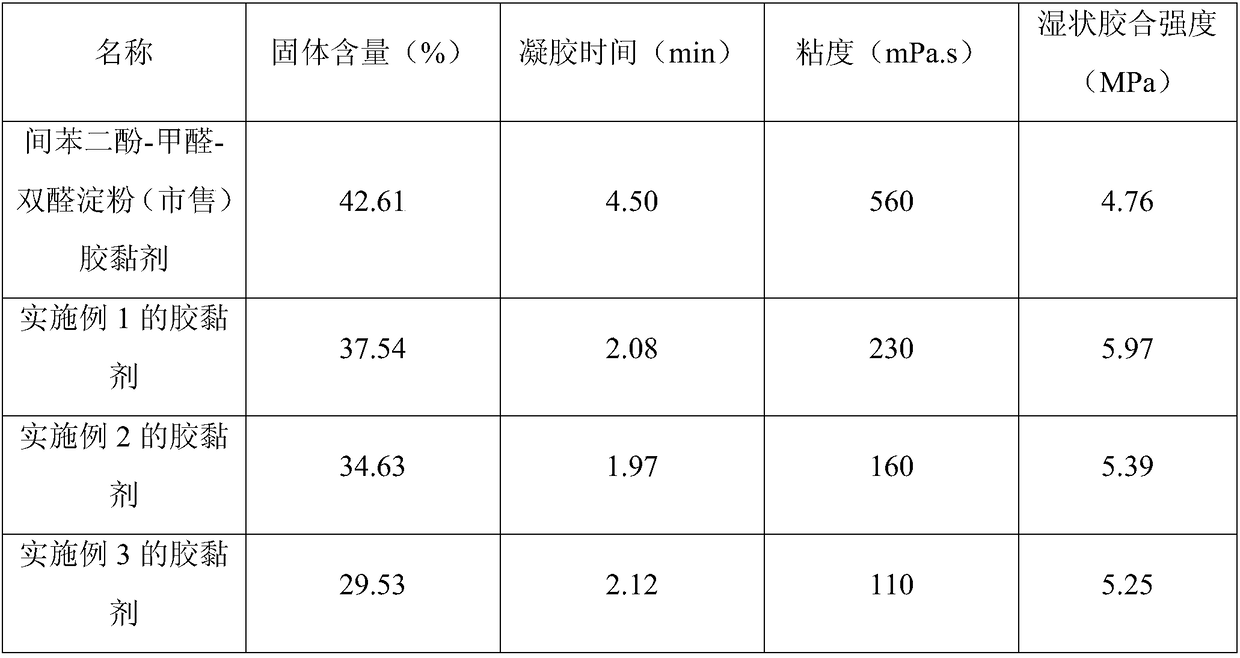

[0030] After testing, the content of aldehyde groups in the dialdehyde starch prepared in this embodiment is 91.71%, and ...

Embodiment 2

[0032] A kind of embodiment of dialdehyde starch preparation method of the present invention, comprises the following steps:

[0033] (1) the sodium periodate of 200 weight parts and the sulfuric acid of 150 weight parts 98wt% are dissolved in the deionized water of 1458 weight parts, then add the potato starch of 162 weight parts, be made into the starch that potato starch massfraction is 8.2% milk.

[0034] (2) Transfer the starch milk obtained in step (1) to a reaction kettle with a stirrer, and perform acidolysis and oxidation reaction in a water bath at 40°C for 3 hours. After the reaction, the obtained material is first washed with deionized water, and then pumped Filtrate until the pH of the filtrate is 7.0 (the material is neutral at this time), and then dry in an oven at 50° C. to obtain the dialdehyde starch of the present invention.

[0035] After testing, the content of aldehyde groups in the dialdehyde starch prepared in this embodiment is 87.48%, and the average...

Embodiment 3

[0037] A kind of preparation method of dialdehyde starch of the present invention, comprises the following steps:

[0038] (1) the sodium periodate of 257 parts by weight, the hydrochloric acid of 225 parts by weight 36.5wt% and the sulfuric acid of 75 parts by weight 98wt% are dissolved in the deionized water of 3888 parts by weight, then add the rice starch of 162 parts by weight, be made into Starch milk with a mass fraction of rice starch of 3.5%.

[0039] (2) Transfer the starch milk obtained in step (1) to a reaction kettle with a stirrer, and perform acidolysis and oxidation reaction in a water bath at 50°C for 0.5 hours. After the reaction, the obtained material is first washed with deionized water, and then pumped Filter until the pH of the filtrate is 7.0 (the material is neutral at this time), and then place it in an oven at 60° C. to dry to obtain the dialdehyde starch of the present invention.

[0040] After testing, the content of aldehyde groups in the dialdehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com