Dialdehyde nanocellulose with high substitution degree and preparation method thereof

A technology of nanocellulose and high degree of substitution, applied in the field of dialdehyde nanocellulose with high degree of substitution and its preparation, can solve the problem of reducing the selective oxidation efficiency of sodium periodate, unstable nanocellulose, and limiting aldehyde group substitution Problems such as speed, to achieve the effect of short time-consuming, low equipment requirements, and reduced reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

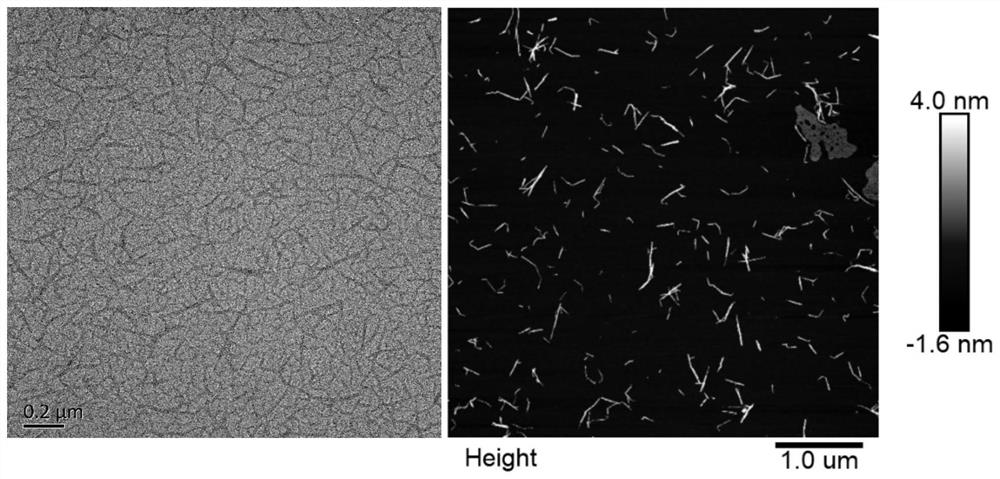

[0072] Example 1 Preparation of nanocellulose

[0073] 1. Nanocellulose Suspension 1

[0074] Using cellulose as raw material, each gram of cellulose is dispersed in 100mL of phosphate buffer solution (0.05mol / L, pH7) to form a 1% (w / v) slurry, and 0.016g of TEMPO reagent is added, 0.9g NaClO with 80% purity 2 and 3 mL of NaClO solution with a concentration of 2.5% at 60° C. under magnetic stirring at 500 rpm for 6 h, and then added 100 mL of absolute ethanol to terminate the reaction. Use deionized water to repeatedly wash the obtained oxidized cellulose sample until the pH of the solution = 7. The precipitated slurry collected by filtration under reduced pressure is oxidized cellulose, and deionized water is added to the oxidized cellulose to make 1.0% (w / v ) concentration of the suspension, using an ultrasonic cell disruptor (configured with a cylindrical titanium alloy probe with a diameter of 20mm, JY99-IIID, Ningbo Xinzhi Biotechnology Co., Ltd., China), in an ice-wate...

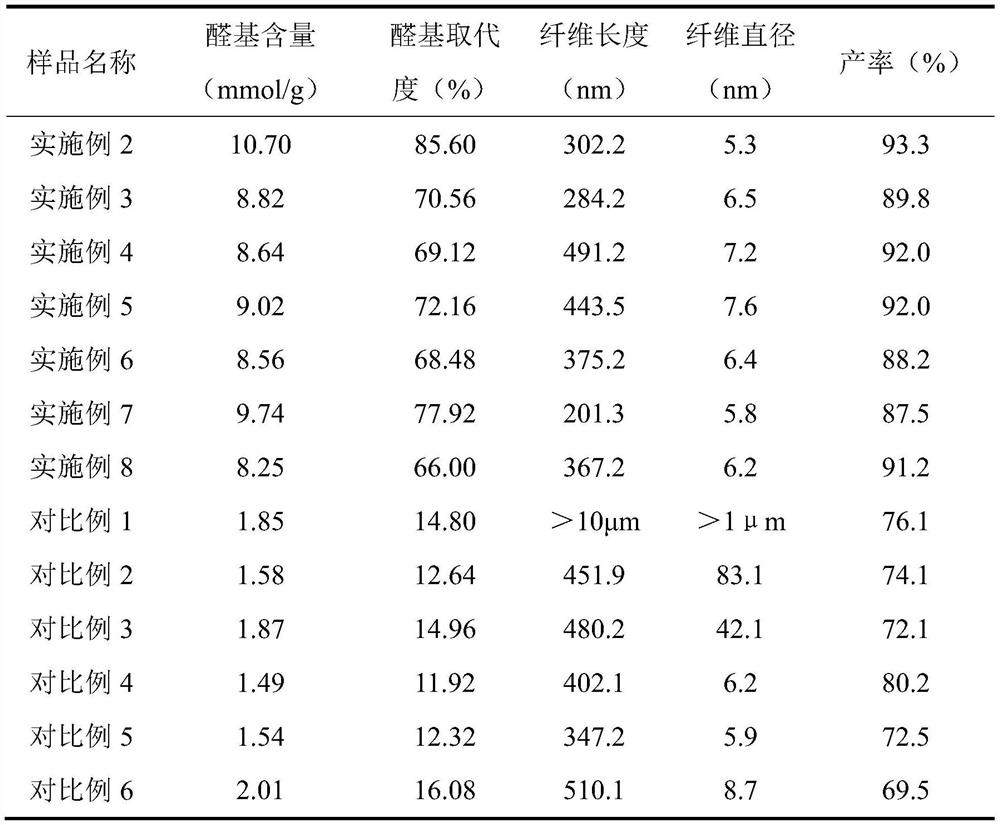

Embodiment 2

[0079] Embodiment 2 A kind of dialdehyde nanocellulose with high degree of substitution

[0080] (1) in the nanocellulose suspension 1 prepared in Example 1, add dilute hydrochloric acid to carry out cation exchange reaction, until the pH of the suspension drops to 2, the suspension after the reaction is sheared at high speed for 10min at a rotating speed of 10000r / min, After mechanical ultrasonic disassembly at 300W power for 15s, the precipitated slurry was collected by decompression filtration using qualitative filter paper, and deionized water was added to the slurry to redisperse into a 1.0% (w / v) concentration of de-sodium nanocellulose suspension. Measure the pH of the suspension. The above-mentioned high-speed shearing, ultrasonic disassembly, filtration under reduced pressure and redispersion were repeated until the pH of the suspension rose to 7.

[0081] (2) Take 50 mL of the 1.0% (w / v) de-sodiumized nanocellulose suspension prepared in step (1), add 50 mL of aceti...

Embodiment 3

[0083] Embodiment 3 A kind of dialdehyde nanocellulose of high degree of substitution

[0084] Same as Example 2, the difference is that the nanocellulose suspension 1 in step (1) is replaced with the nanocellulose suspension 2 prepared in Example 1, and other operations are the same as those in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com