Preparing method for low-carbon steel super-hydrophobic surface

A super-hydrophobic surface and low-carbon steel technology, which is applied in the coating process of metal materials, etc., can solve the problems of 3-8 hours of corrosion time, complex process, and difficult control of surface uniformity, and achieve low equipment requirements and simple operation , the effect of good superhydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

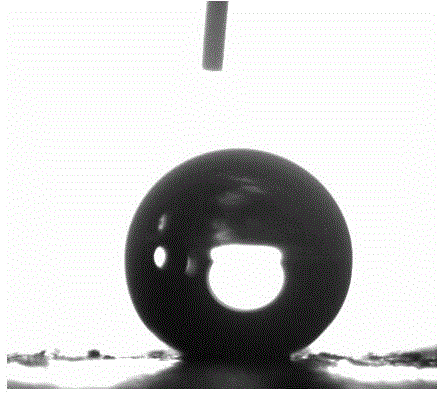

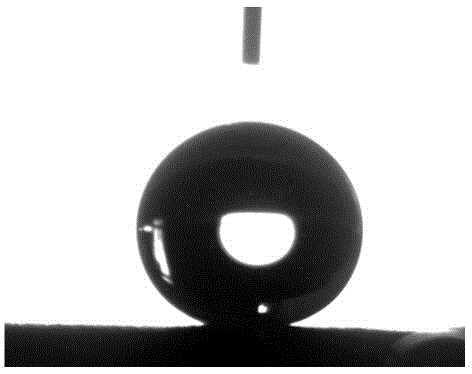

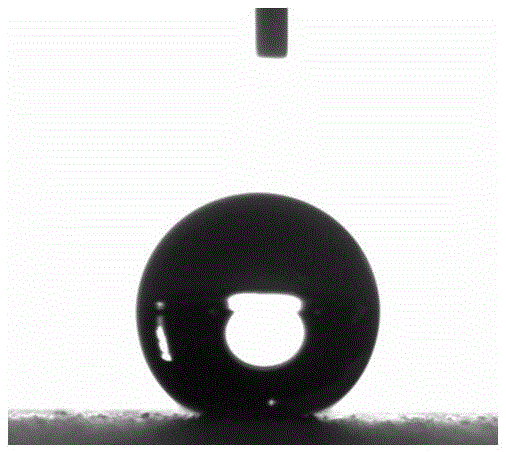

Image

Examples

Embodiment 1

[0020] This embodiment provides a method for preparing a low-carbon steel superhydrophobic surface, which specifically includes the following steps:

[0021] (1) Pretreatment: Use 400#SiC sandpaper to remove the surface oxide layer and oil stains of low carbon steel (main components are C0.13%, Mn0.6%, Si0.01%, P0.015%, S0.05%) , placed in 99% acetone and 99% ethanol in turn for 10 minutes, took it out and dried it quickly.

[0022] (2) Salt spray corrosion of the pretreated low carbon steel: put the steel sheet in a salt spray test chamber with a salt spray pH value of 7.2, a mass concentration of 5% NaCl, a temperature of 32°C, and a spray pressure of 100kPa Take it out after 60min.

[0023] (3) The corroded low-carbon steel is taken out, washed with distilled water, and then dried at 120°C for 30 minutes.

[0024] (4) After drying, the low-carbon steel is modified with low surface energy. The low-carbon steel is soaked in an ethanol solution with a mass concentration of 1...

Embodiment 2

[0026] This embodiment provides a method for preparing a low-carbon steel superhydrophobic surface, which specifically includes the following steps:

[0027] (1) Pretreatment: Use 1200#SiC sandpaper to remove the surface oxide layer and oil stains of low carbon steel (main components are C0.13%, Mn0.6%, Si0.01%, P0.2%, S0.05%) , placed in 99% acetone and 99% ethanol in turn for 10 minutes, took it out and dried it quickly.

[0028] (2) Salt spray corrosion of the pretreated low carbon steel: put the steel sheet in a salt spray test chamber with a salt spray pH value of 7.0, a mass concentration of 5% NaCl, a temperature of 30°C, and a spray pressure of 90kPa Take it out after 120min.

[0029] (3) The corroded low-carbon steel was taken out, washed with distilled water, and then dried at 110°C for 40 minutes.

[0030] (4) After drying, the low-carbon steel is modified with low surface energy. The low-carbon steel is soaked in an ethanol solution of heptadecafluorodecyltrietho...

Embodiment 3

[0032] This embodiment provides a method for preparing a low-carbon steel superhydrophobic surface, which specifically includes the following steps:

[0033] (1) Pretreatment: Use 800#SiC sandpaper to remove the surface oxide layer and oil stains of low carbon steel (main components are C0.13%, Mn0.7%, Si0.01%, P0.15%, S0.05%) , placed in 99% acetone and 99% ethanol in turn for 10 minutes, took it out and dried it quickly.

[0034] (2) Salt spray corrosion of the pretreated low carbon steel: put the steel sheet in a salt spray test chamber with a salt spray pH value of 6.8, a mass concentration of 5% NaCl, a temperature of 33°C, and a spray pressure of 70kPa Take it out after 80min.

[0035] (3) The corroded low-carbon steel is taken out, washed with distilled water, and then dried at 100°C for 50 minutes.

[0036] (4) The dried low-carbon steel is modified with low surface energy, soaked in an ethanol solution of 1% dodecanethiol for 5 minutes, then taken out and rinsed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com