Hollow adjustable polymer blending device

An adjustable and polymerizing device technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of heavy on-site workload, scaling and blockage of annular choke channels, and small injection volume control , to achieve the effects of small measuring and adjusting workload, preventing blockage and high adjusting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

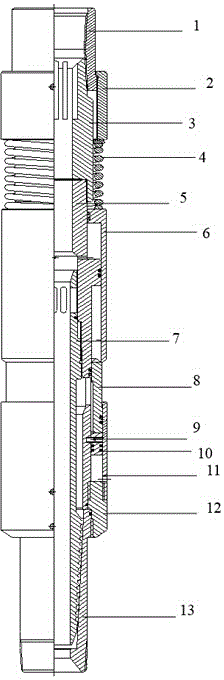

[0013] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0014] Refer to attached figure 1 , a hollow adjustable polymerizer, including a center tube 5, an adjustment core 7, a stab-proof piston 6, and a sealing piston 8, the adjustment core is inserted at the lower end of the center tube and connected in the inner cavity of the center tube, and the adjustment core and The inner cavity of the central tube is connected. The anti-stab piston and the sealing piston are set on the outside of the central tube one by one, and the anti-stab pistons form an upper piston cavity with each other. The central tube is opened to communicate with the upper piston. cavity and the upper through hole of the center tube inner cavity; the bottom end of the center tube and the outside of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com