Detection method and system of surface thickness and planeness of rotary target

A detection method and detection system technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of errors, inability to directly reflect the thickness of the rotating target spraying target material, and the difficulty of directly detecting the thickness of the spraying target material, etc., to achieve The effect of improving precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

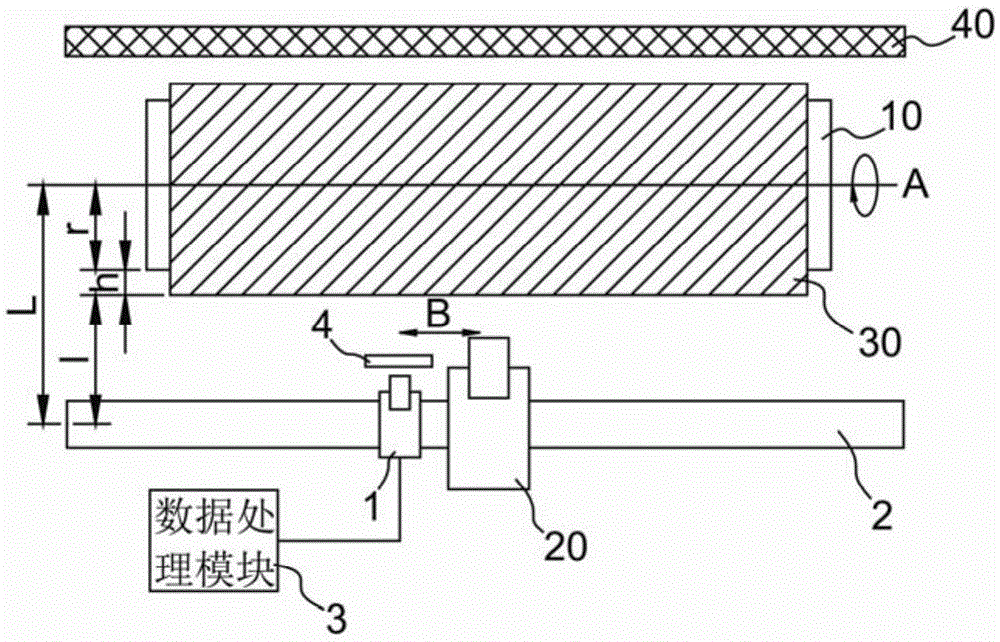

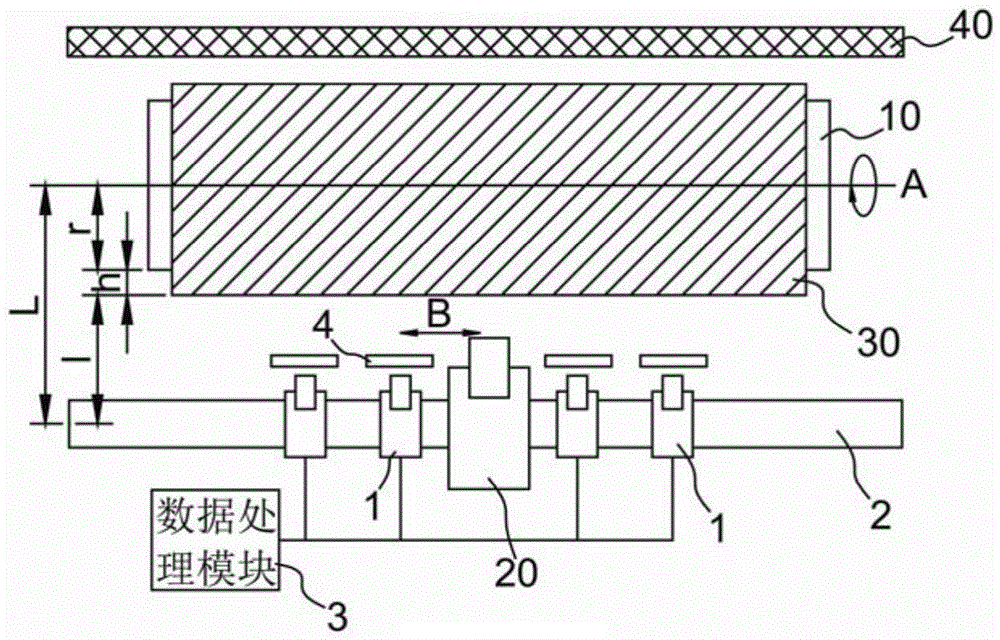

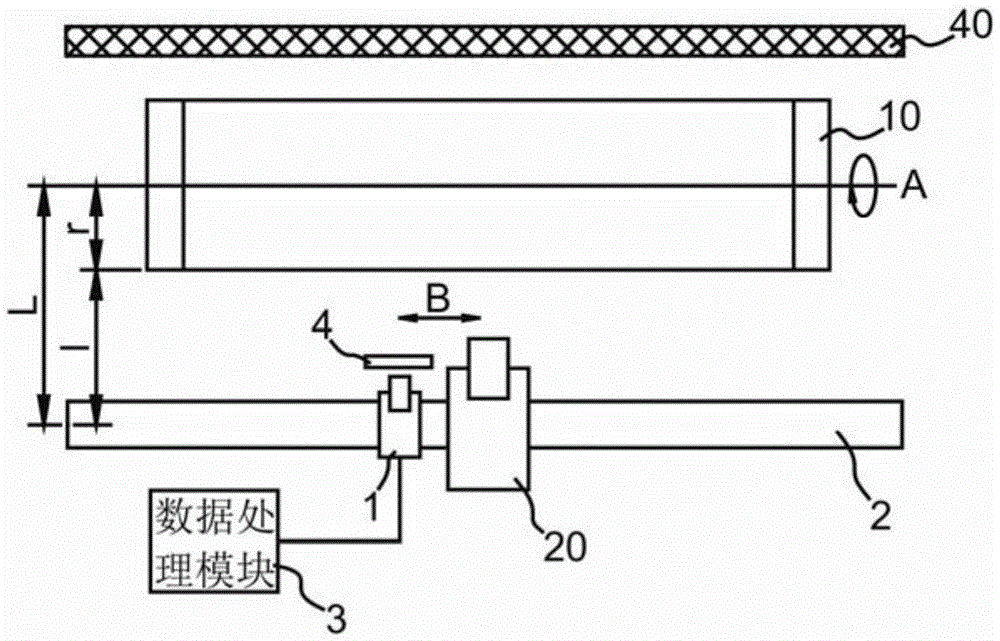

[0031] figure 1 Schematically shows the working principle of the detection system according to an embodiment of the present invention, wherein, before spraying, the distance measuring module 1 is installed on one side of the revolving body 10, and the baffle 40 is installed on the other side of the revolving body 10, And the distance between the ranging module 1 and the axis A of the rotating body 10 is a fixed value L, and the ranging module 1 is driven by the driving module 2, so that the ranging module 1 can reciprocate along the axial direction of the rotating target 1 (direction B) , preferably the distance measuring module 1 and the spray gun 20 are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com