Arc end tooth addendum measuring method

An arc end tooth and measurement method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of limited end tooth size range, affecting end face imaging clarity, non-standard measurement methods, etc., to achieve easy grasp, measurement data and Stable repeatability and convenient promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

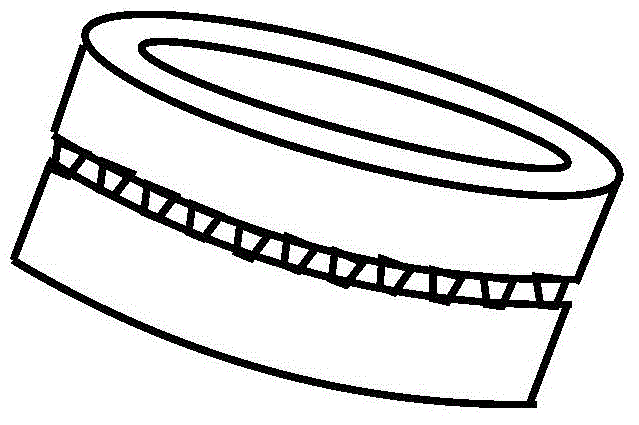

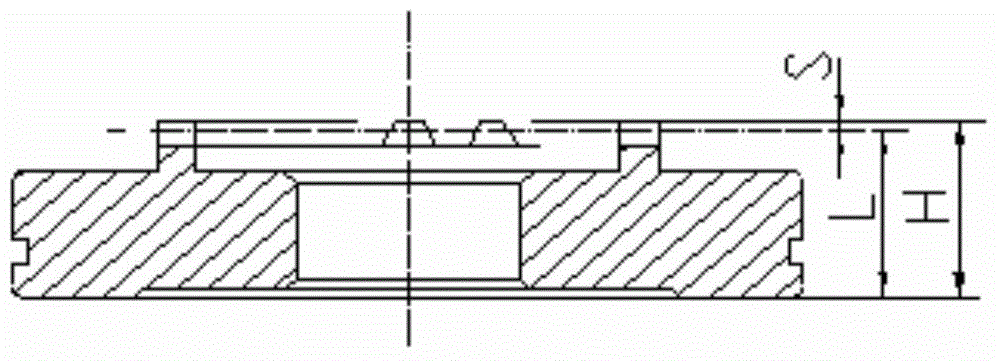

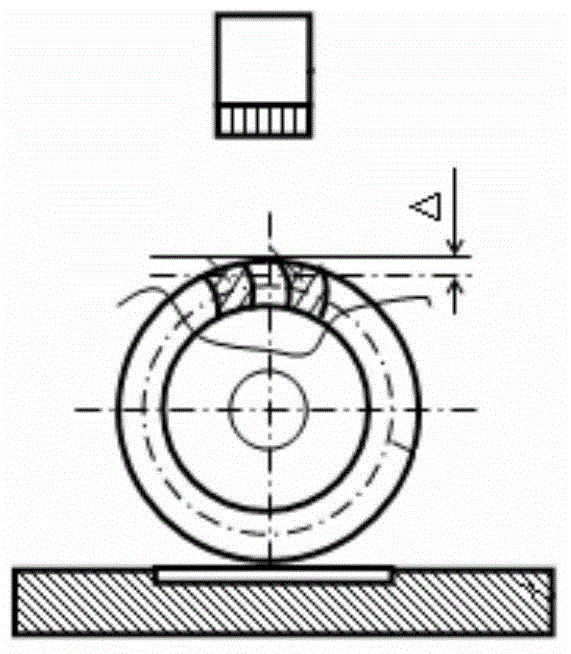

[0034] The steps of the method of measuring the height of the tooth top at the circular arc end are as follows:

[0035] ①In order to meet the requirement that the actual measurement position is consistent with the theoretical position, the scanning probe (1) of the three-coordinate measuring machine is used to measure the height of the tooth top of the arc end, and the cylindrical scanning function is used at the end tooth pitch circle to collect the standard concave The actual profile data points of the tooth; avoiding the error caused by the unequal focal length of the optical measurement, the text data CURVE (1) is a three-dimensional polar coordinate value; its three-dimensional graphics are as follows Image 6 .

[0036] First, establish a Cartesian coordinate system; measure the reference plane A, determine the z-axis direction and the xoy plane, and then measure the reference hole, set the center of the circular hole as the coordinate origin o, and set any direction as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com