Distributed optical fiber temperature sensor calibration and correction constant temperature device

A technology of temperature sensor and distributed optical fiber, which is applied in thermometer testing/calibration, thermometers, measuring devices, etc., can solve the problems of high stable temperature accuracy and fast temperature response, and achieve high stable temperature precision, fast temperature response, and simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

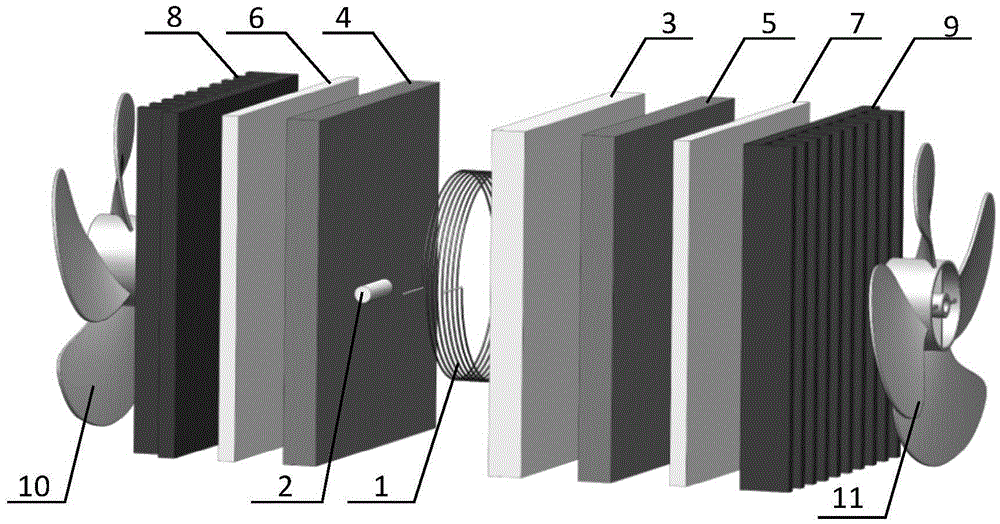

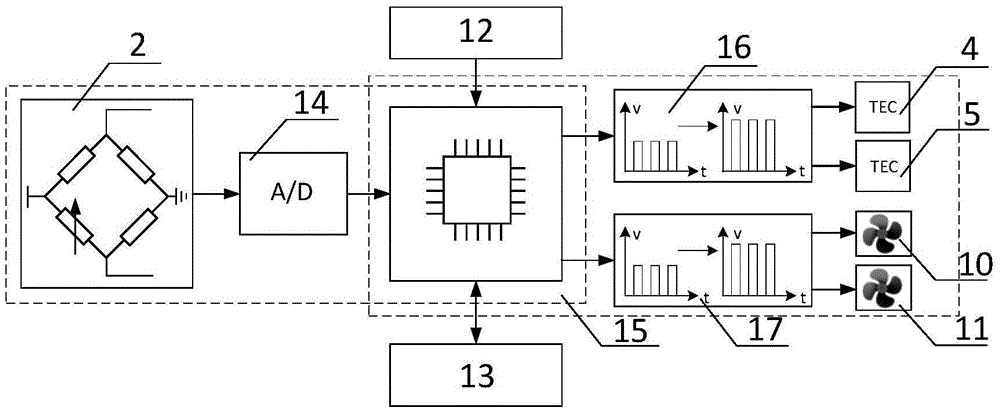

[0016] Attached below figure 1 And attached figure 2 Further illustrate the use of a distributed optical fiber temperature sensor calibration and constant temperature device of the present invention to use the optical fiber ring to perform temperature calibration and calibration in the distributed optical fiber temperature measurement system, and the constant temperature device of the present invention to perform temperature measurement and temperature control on the optical fiber ring working principle.

[0017] According to attached figure 1 Fiber optic ring 1, temperature sensor probe 2, middle thermal silica gel 3, left semiconductor cooling plate 4, right semiconductor cooling plate 5, left thermal silica gel 6, right thermal silica gel 7, left heat sink 8, right heat sink 9, left cooling fan 10 and the right heat dissipation fan 11 are assembled into a distributed optical fiber temperature sensor calibration and constant temperature device. The fiber optic ring 1 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com