Detection method of sandbox sealing performance

A detection method and sealing technology are applied in the detection field of sand box sealing, which can solve the problems of drop of vacuum degree of sand box, insufficient negative pressure, collapse of sand box, etc., and achieve flexible operation, guaranteed vacuum degree and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

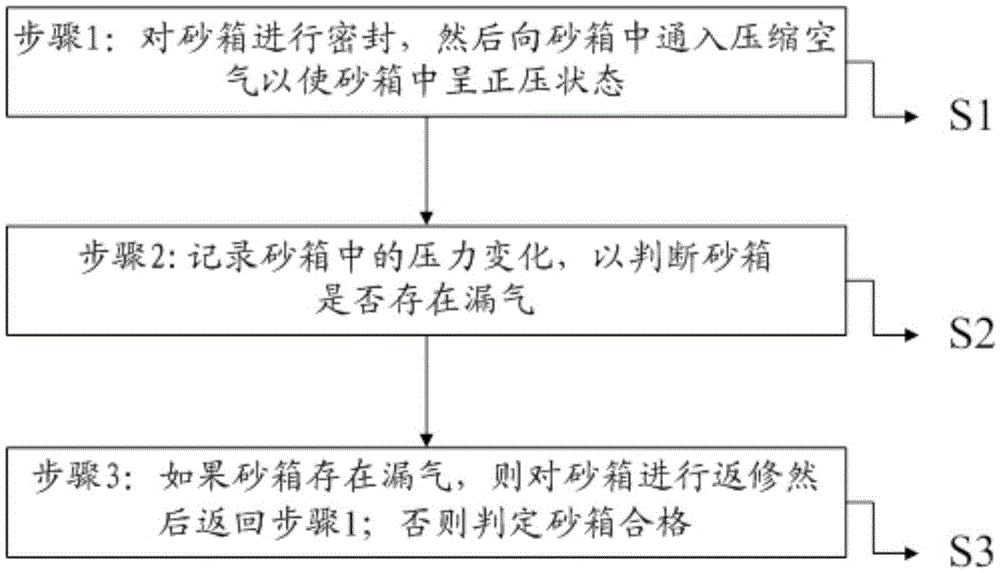

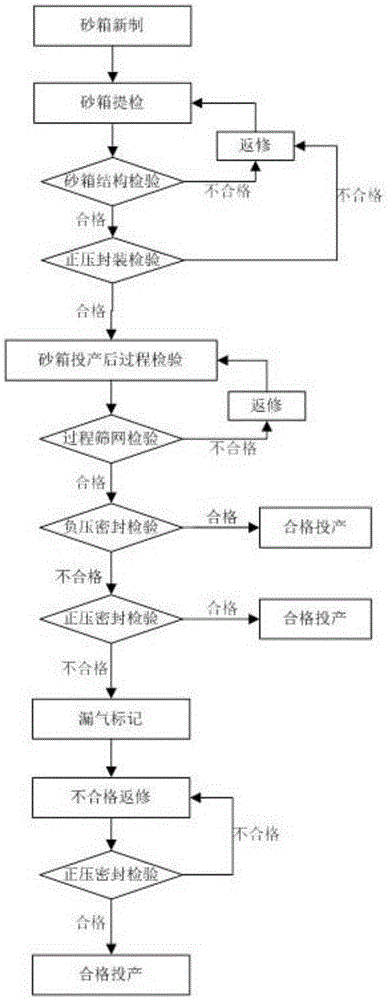

[0036] figure 1 It is a schematic flow chart of an embodiment of the testing method for the tightness of the sand box 1 of the present invention. Such as figure 1 As shown, the method for testing the airtightness of the flask 1 in this embodiment may include the following steps.

[0037] S1: Step 1: Seal the sand box 1, and then pass compressed air into the sand box 1 to make the sand box 1 in a positive pressure state.

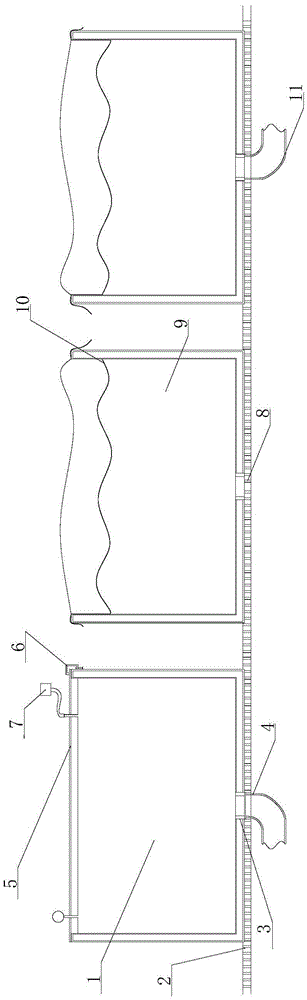

[0038] Specifically, turn the sand box 1 to the detection station on the detection track 2, then connect the vacuum docking hole 3 at the bottom of the sand box 1 with the hydraulic sealing valve 4, and install the top sealing cover 5 with the sand box 1 , and use the standard C-type card 6 to clamp firmly, connect the sand box 1 with the compressed air valve 7 through the compressed air hole on the top sealing cover, and then pass compressed air into the sand box 1 to make the sand box 1 positive pressurized state for inspection.

[0039] S2: Step 2: Rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com