A device and method for damage detection of composite materials using Lamb guided waves

A technology for damage detection and composite materials, which is applied in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, and material analysis, which can solve the problems of low detection efficiency and inability to detect damage paths of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

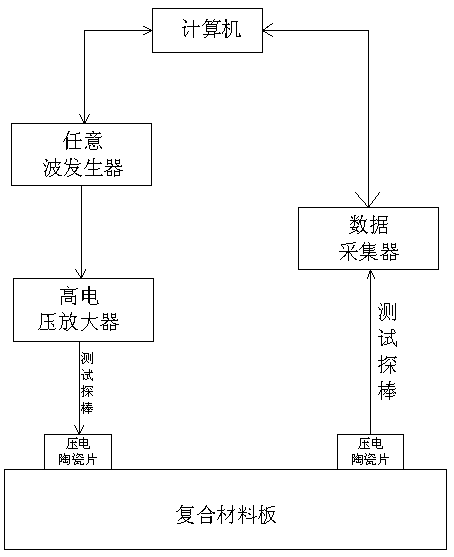

[0042] Such as figure 1As shown, the device for damage detection of composite materials using Lamb guided waves according to the present invention includes composite material plates, multiple PZT sensors, arbitrary wave generators, high-voltage amplifiers, data collectors and computers, wherein the PZT The number of sensors is not less than 4 and the position of the PZT sensor is symmetrical with respect to the center of the upper surface of the composite material board. The computer is connected to the arbitrary wave generator through communication. The output end is electrically connected to the PZT sensor through the test probe, the computer is used to control the arbitrary wave generator to send the excitation signal, the high voltage amplifier is used to amplify the excitation signal, and the data collector is used to collect the response signal generated by the PZT sensor after being excited And transmit the response signal to the computer, the computer is also used to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com