Color filter and making method thereof and photomask used for making color filter

A color filter and color filter film technology, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of process technology to be improved and high production cost, so as to reduce production time and production cost, simplify the process, save Effect of demask and process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

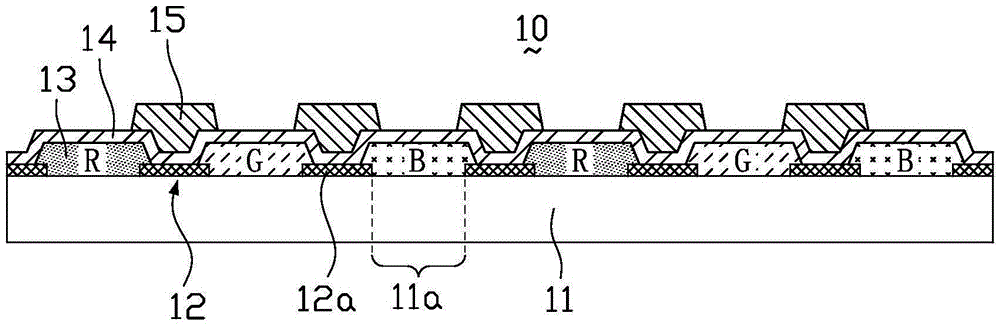

[0036] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

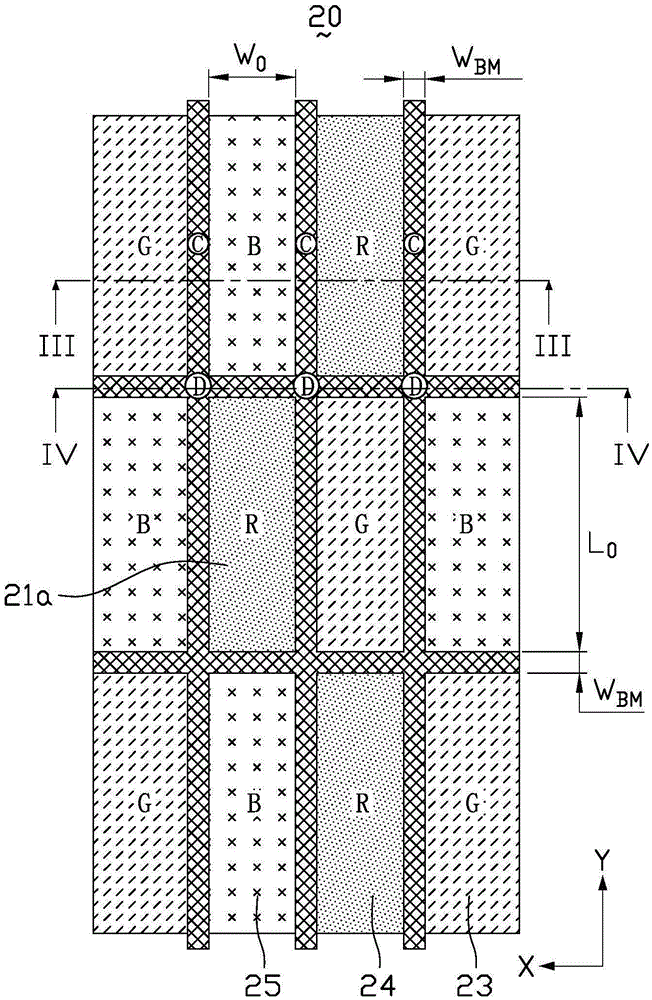

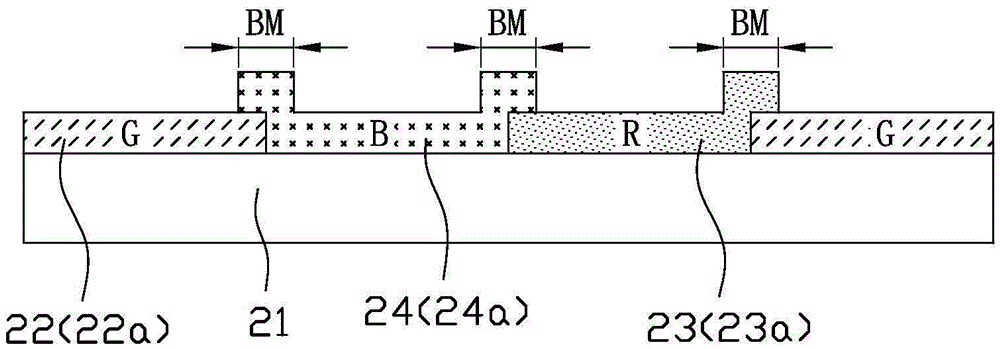

[0037] figure 2 is a partial plan view of the color filter of the embodiment of the present invention, image 3 yes figure 2 A schematic cross-sectional view along line III-III, Figure 4 yes figure 2 A schematic cross-sectional view along line IV-IV. Please refer to Figure 2 to Figure 4The color filter 20 of the embodiment of the present invention includes a base substrate 21 and a first color filter film 22 , a second color filter film 23 and a third color filter film 24 formed on the base substrate 21 . The first color filter film 22 is, for example, a green filter film G, the second color filter film 23 is, for example, a red filter film R, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com