Design method of static aeroelasticity test model

A technology of model design and static aeroelasticity, which is applied in the field of aerospace engineering, can solve problems affecting model aerodynamic force, high additional stiffness, and high mold requirements, and achieve the effects of low difficulty in test processing, simple design process, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

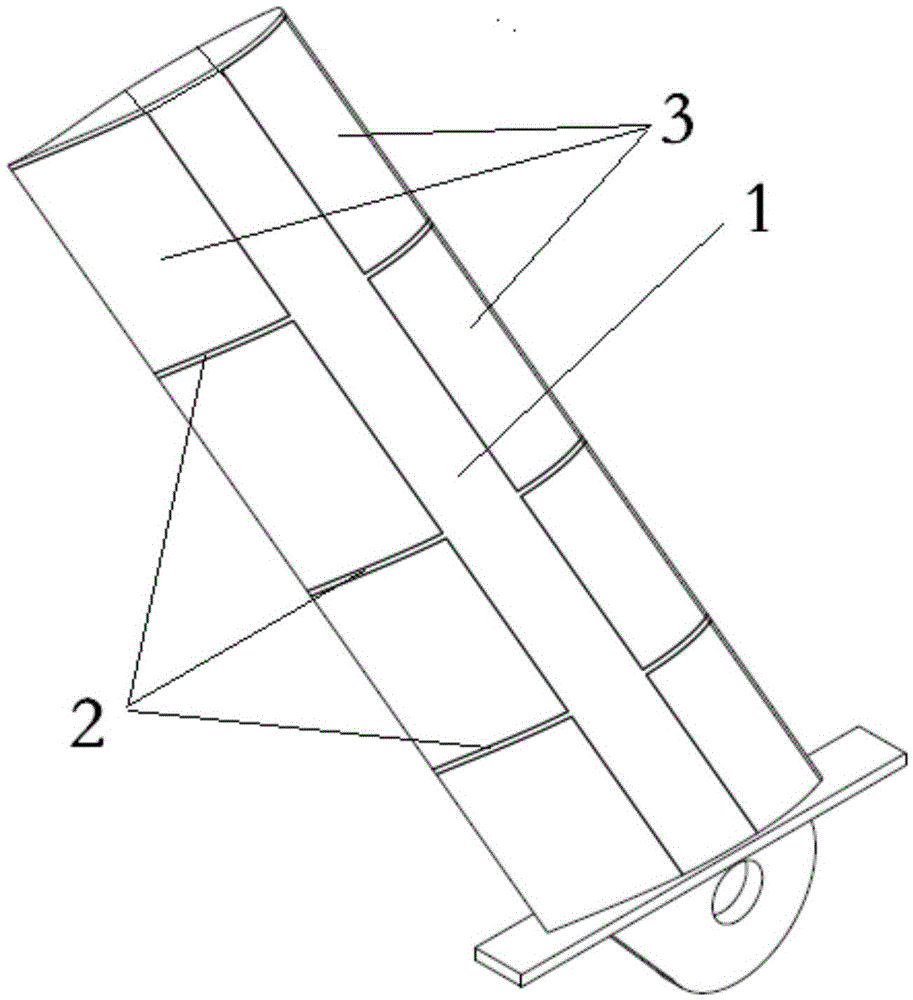

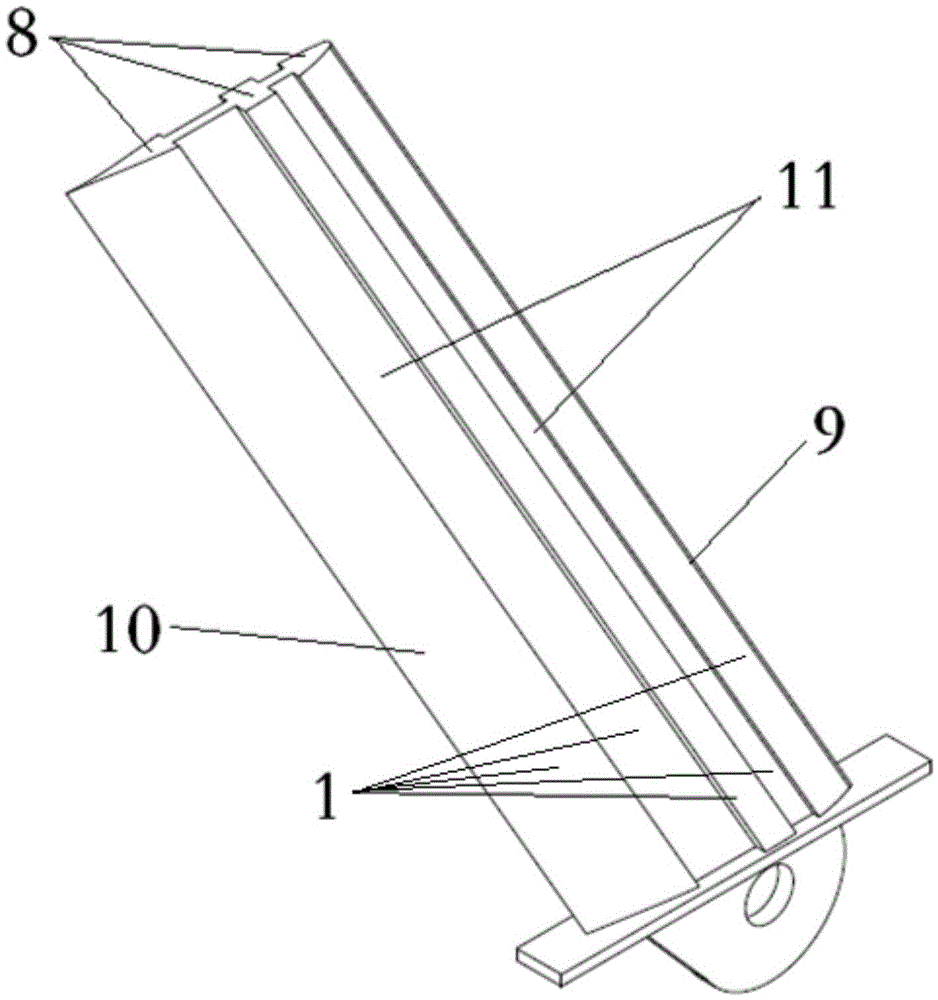

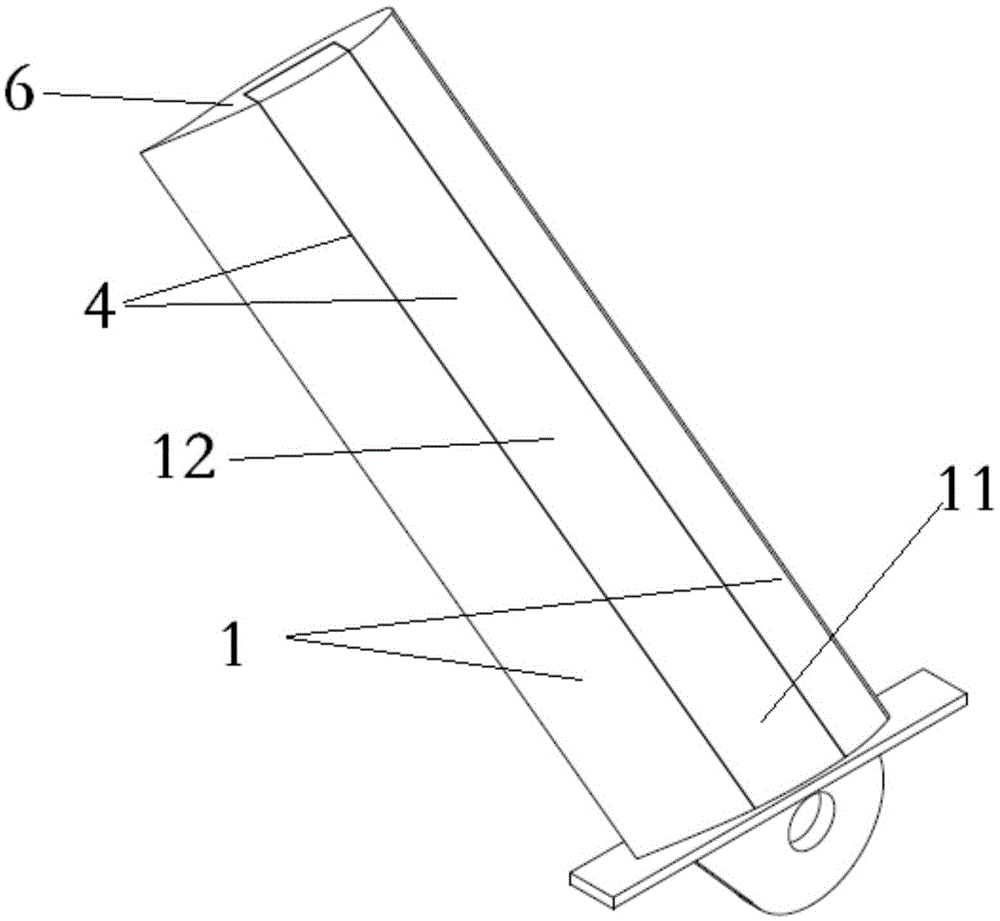

[0026] like figure 2 , image 3 As shown, the present invention includes metal girder 1 , rigid foam 12 and surface paint 4 .

[0027] First, the section stiffness required by the model will be calculated through the similarity relationship of the model design, and the model section design will be carried out by using the relevant 3D modeling software; the actual section stiffness of the model will be consistent with the required section stiffness of the model. The designed model section covers the leading edge 9 and the trailing edge 10 of the wing. Metal materials are then used to manufacture the model main beam 1, which includes the leading edge 9 and the trailing edge 10 of the airfoil. Then apply glue inside the groove 11 of the main beam, fill it with hard foam 12, and polish the edges of the foam to ensure that the shape of the model is consistent with the aerodynamic shape that the wing model should have. Finally, the surface of the foam 12 on the wing and the foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com