Fan-dedicated cable

A technology for special cables and fans, applied in the field of special cables for fans, can solve the problems affecting the reliability of wind power generation, environmental pollution, etc., and achieve the effects of being conducive to natural hanging, improving mechanical performance and simple structure

Inactive Publication Date: 2016-06-08

程学武

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, with the large-scale use of coal, the environment is becoming more and more polluted. The air contains a large number of flying dust particles, which greatly affects people's lives. The demand for new energy is becoming more and more urgent. As a new pollution-free Energy has received more and more attention. The performance of wind energy cables connected to wind turbines greatly affects the reliability of wind power generation. Since the various components of wind power generation are generally in harsh environments, wind energy cables are required to withstand high temperature and low temperature. Change, corrosion resistance, aging resistance, radiation resistance, tensile strength, high flexibility and twist resistance, etc., but the existing cables cannot meet the above requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

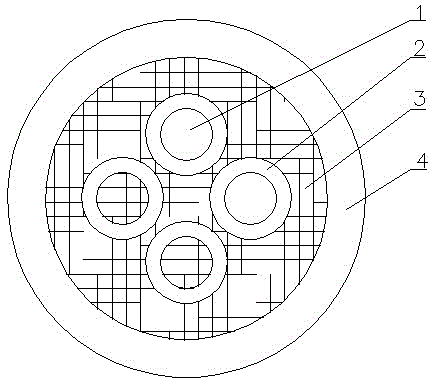

[0010] exist figure 1 Among them, each core 1 of the fan special cable is wrapped with stainless steel wire shielding layer 2, and several cores 1 with stainless steel wire shielding layer 2 are wrapped in ethylene-propylene rubber insulating layer 3, and ethylene-propylene rubber insulating layer 3 is wrapped with PUR Sheath layer 4 composed of elastomeric compound.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Disclosed is a fan-dedicated cable. A plurality of wire cores each coated with a stainless steel wire shielding layer are wrapped in an ethylene-propylene rubber insulation layer. The ethylene-propylene rubber insulation layer is covered with a sheath layer composed of a PUR elastomer compound. By simplifying the cable structure and choosing a low-density ethylene-propylene rubber insulation material, the weight of the cable is reduced. Each core wire is separately wrapped in a stainless steel wire shielding layer, so that an electromagnetic shielding effect is achieved, and the tensile, compressive and distortion-resistant mechanical properties of the wire cores are improved.

Description

technical field [0001] The invention relates to a special cable for wind power generators, especially suitable for use from wind power generators to the vertical part of the ground. Background technique [0002] At present, with the large-scale use of coal, the environment is becoming more and more polluted. The air contains a large number of flying dust particles, which greatly affects people's lives. The demand for new energy is becoming more and more urgent. As a new pollution-free Energy has received more and more attention. The performance of wind energy cables connected to wind turbines greatly affects the reliability of wind power generation. Since the various components of wind power generation are generally in harsh environments, wind energy cables are required to withstand high temperature and low temperature. Change, corrosion resistance, aging resistance, radiation resistance, tensile strength, high flexibility and twist resistance, etc., but the existing cables ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01B7/02H01B7/17H01B7/18H01B7/28

CPCY02A30/14

Inventor 程学武

Owner 程学武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com