Ultrathin elevator button

A pushbutton and elevator technology, applied in the direction of circuits, electric switches, electrical components, etc., can solve the problems of complex parts, inability to meet the button assembly requirements, and large button thickness, so as to achieve the effects of saving internal space, prolonging service life, and uniform momentum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

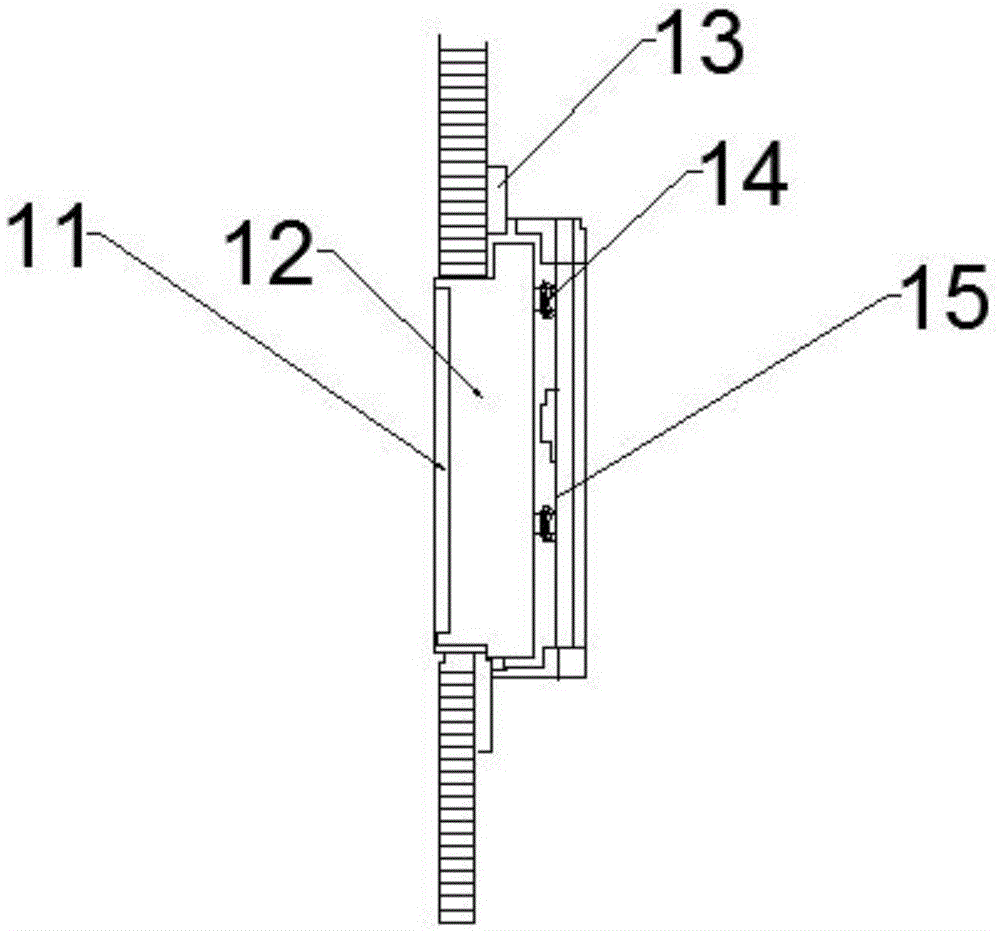

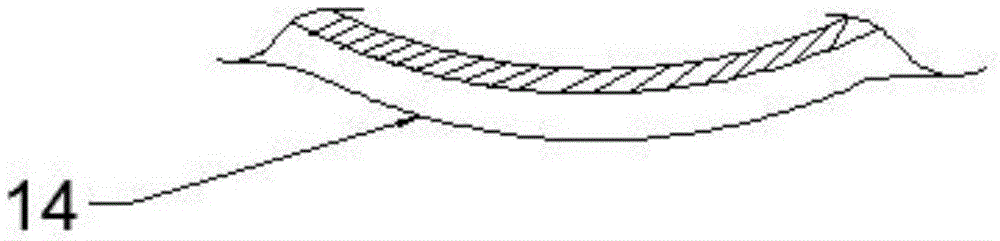

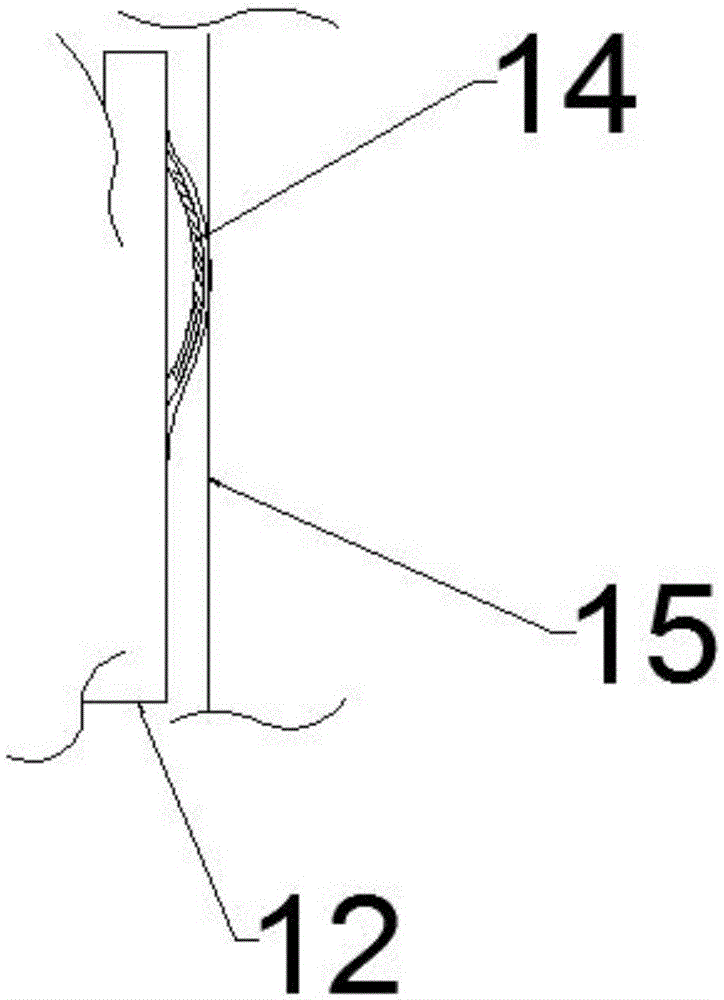

[0031] The invention discloses an ultra-thin elevator button, such as figure 1Shown: schematically shows the structural components of the elevator button, including the button tablet 11, the button pusher 12, the button housing 13, several elastic bodies 14 and the PCB board 15; the above-mentioned components are connected and assembled in sequence Finally, the use of elevator buttons can be realized, and the thickness of the buttons can be reduced to about 9-10mm, which saves the internal space of the elevator control device, reduces the installation time and reduces the cost of parts production. Specifically, the button letter 11 is bonded to the button pusher 12, and the specific bonding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com