Embedded connectors for aircraft

A technology for connectors and aircraft, applied in the direction of connecting components, thin plate connections, threaded fasteners, etc., can solve the problem of the manufacturing process of embedded connectors that cannot meet the high-efficiency production needs of aerospace vehicles and cannot be used. Complexity and other issues, to achieve the effect of flexible design and production, improved reliability, and conducive to engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

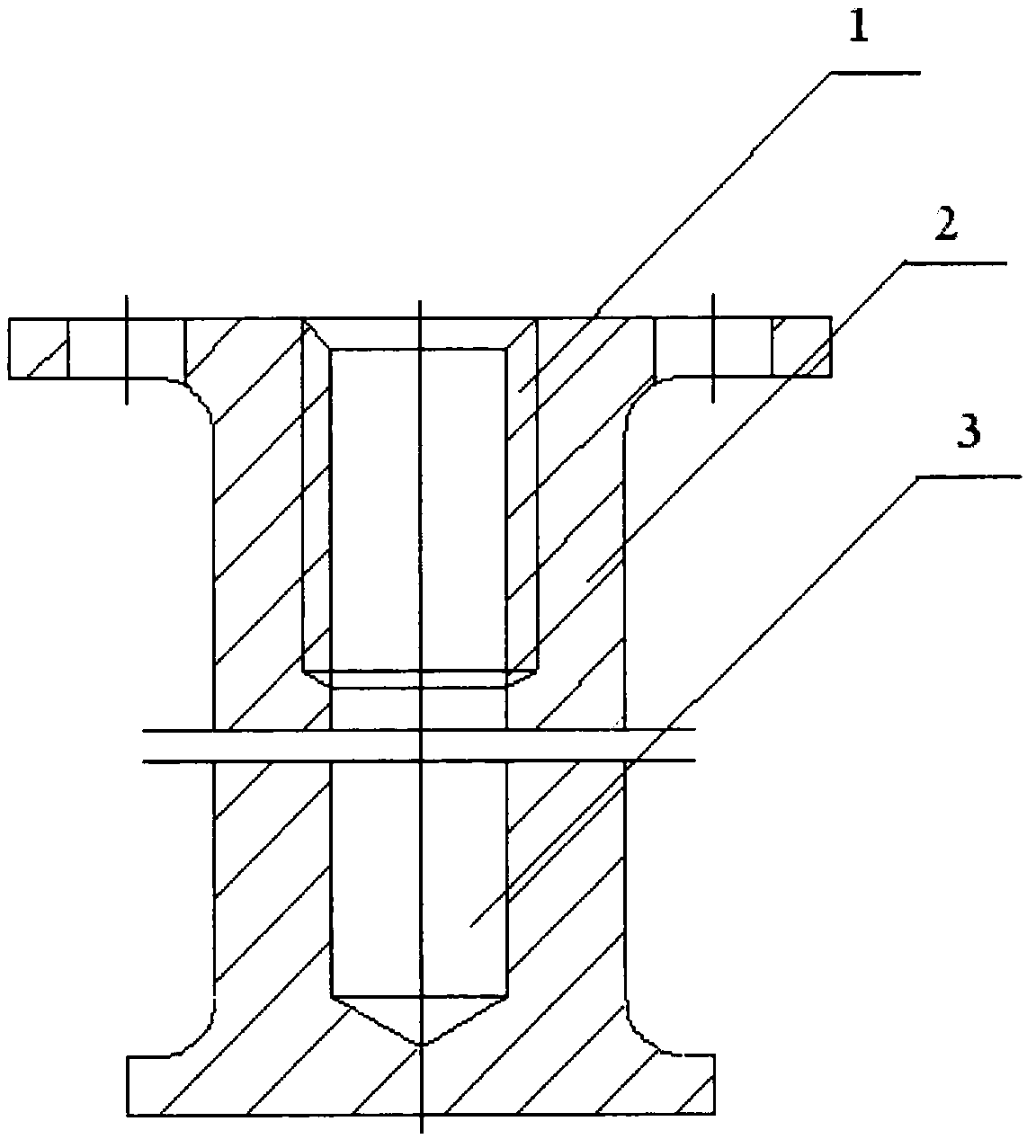

[0011] as attached figure 1 As shown, an embedded connector for an aircraft uses Al-Zn-Mg-Cu aluminum alloy as the base 2, and the weight percentage of the aluminum alloy is: Zn: 5.4-5.8%, Mg: 2.7-3.5%, Cu: 1.6- 2.2%, Cr: 0.2-0.35%, Mn: 0.15-0.35%, Ti: 0.05-0.15%, Ni: 0.01-0.1%, Fe: 0-0.35%, Si: 0-0.15%, and the rest is Al.

[0012] A bottom hole 3 is arranged axially on the aluminum alloy substrate 2, and an internal thread 1 is tapped on the upper part of the bottom hole 3, and the internal thread 1 is treated by phosphoric acid anodization.

[0013] In addition to the above-mentioned Al-Zn-Mg-Cu aluminum alloy materials, the aluminum alloy materials used in the present invention can meet the following requirements, and the high-strength aluminum alloys mentioned in the present invention refer to aluminum alloys that meet the requirem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com