Evaporation chamber of gaseous organic pollutant generator

A technology of organic pollutants and evaporation chambers, applied in the field of evaporation chambers, can solve the problems of unstable concentrations of pollutants, and achieve the effects of fast mechanical strength, avoiding pollution and obvious advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

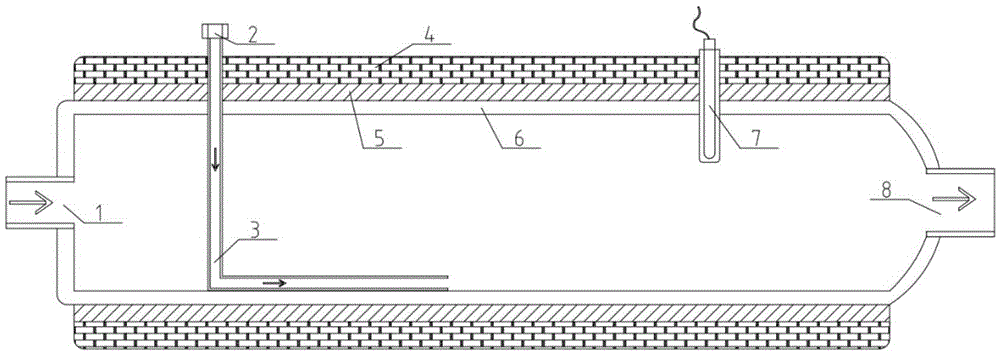

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] The evaporation chamber of the gaseous organic pollutant generator of the present invention includes an evaporation chamber cavity, the left and right sides of the evaporation chamber cavity are respectively provided with a compressed air inlet and a gaseous pollutant outlet, and the outer layer of the evaporation chamber cavity is sequentially provided with electric heating layer and insulation layer, and a capillary gasification tube and a thermocouple are also arranged on the cavity of the evaporation chamber, and the upper end of the capillary gasification tube is provided with an inlet for liquid pollutants.

[0019] The inner diameter of the evaporation chamber is 30-50mm, and the wall thickness is 2-3mm; the inner diameter of the capillary gasification tube is 1-2mm, and the wall thickness is 0.3-0.5mm, all of which are made of 316 stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com