Solid-liquid separation barrel for environmental protection industry

A technology of solid-liquid separation and separation bucket, which is applied in the direction of separation method, sedimentation separation, wastewater treatment of vehicle washing facilities, etc., and can solve the problems of unfavorable collection and separation of small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

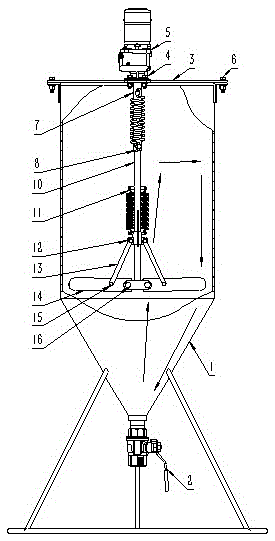

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] Make the cylinder part 1-1 of the solid-liquid separation barrel, the funnel part 1-2, the motor plate mounting ear 1-3, the support feet and the ground ring 1-4, and then install them and weld them into one body as shown in the figure; A valve 2 is installed at the bottom of the funnel part of the liquid separation bucket.

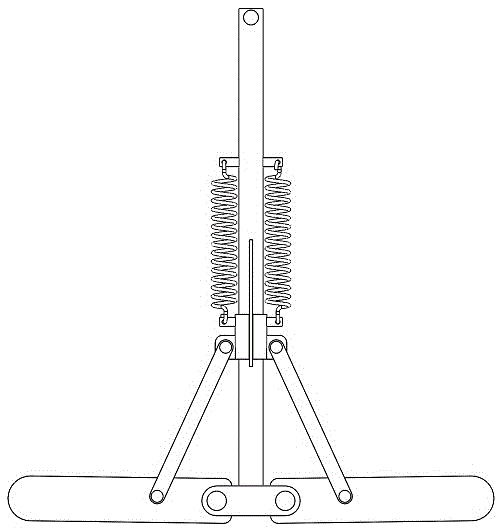

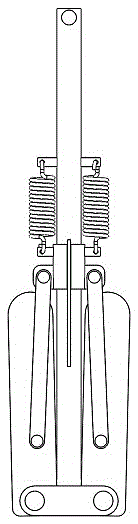

[0027] Use small rivets 15 and large rivets 16 to connect the stirring rod 10, the tension spring 11, the upper and lower cylinders 12, the connecting rod 13, and the stirring paddle 14 into the stirring paddle part 9; the motion guide 10-1 on the stirring rod is connected with threads The method is locked on the stirring rod 10. At this time, the motion guide 10-1 is removed, and then the stirring rod 10 is inserted into the hollow outer shaft 7, and then the motion guide 10-1 is screwed on the stirring rod 10. Finally, the torsion spring...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap