Calcium-based adsorbent for defluoridation and application thereof

A calcium-based adsorbent and weight ratio technology, applied in the direction of adsorption of water/sewage treatment, other chemical processes, silicon compounds, etc., can solve the problems of low efficiency, secondary pollution, poor treatment effect of fluorine-containing wastewater, etc., and achieve adsorption efficiency High, cheap, better effect of fluorine removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take simulated sodium fluoride wastewater, the fluorine concentration is 20mg / L.

[0042] A calcium-based adsorbent for defluoridation of the present embodiment and its application, the steps are:

[0043] (1) Synthesize the dolomite powder calcined product and fly ash at a weight ratio of 1.0 to 2.75:1 at a synthesis temperature of 170°C to 200°C for 6 hours to obtain a calcium-based adsorbent;

[0044] (2) Then add calcium-based adsorbent to the sodium fluoride wastewater, the dosage is 5g / L, magnetically stir for 30min, and separate the solid and water after precipitation.

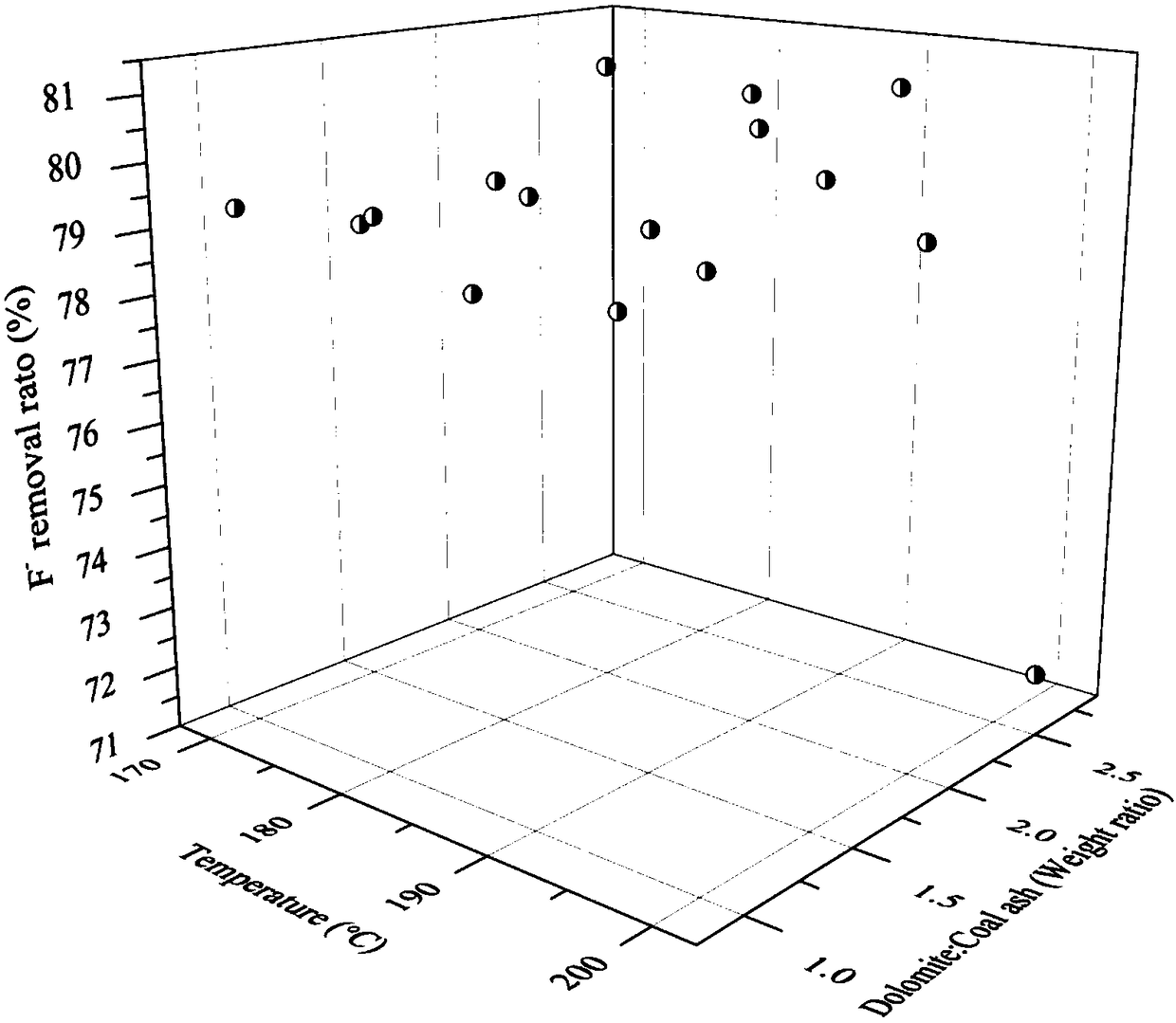

[0045] Such as figure 1As shown, the defluoridation effect under different synthesis temperature and different dolomite: fly ash weight ratio conditions. It can be seen from the figure that under the condition of not adjusting the pH, as the synthesis temperature increases, the fluorine removal efficiency of the calcium-based adsorbent increases first and then decreases, while the change trend ...

Embodiment 2

[0048] The application of a calcium-based adsorbent for defluoridation of this embodiment in the treatment of semiconductor wastewater:

[0049] Take simulated semiconductor wastewater, the fluorine concentration is 20mg / L.

[0050] A calcium-based adsorbent for defluoridation of the present embodiment and its application, the steps are:

[0051] (1) Take the calcined product of dolomite powder and fly ash with a weight ratio of 1.5:1 to synthesize, the synthesis temperature is 180°C, and the time is 6h to obtain a calcium-based adsorbent;

[0052] (2) Adjust the pH value of the wastewater to 2-11, then add calcium-based adsorbent to the wastewater at a dosage of 1.25g / L, stir magnetically for 10min, and separate the solid and water after centrifugation.

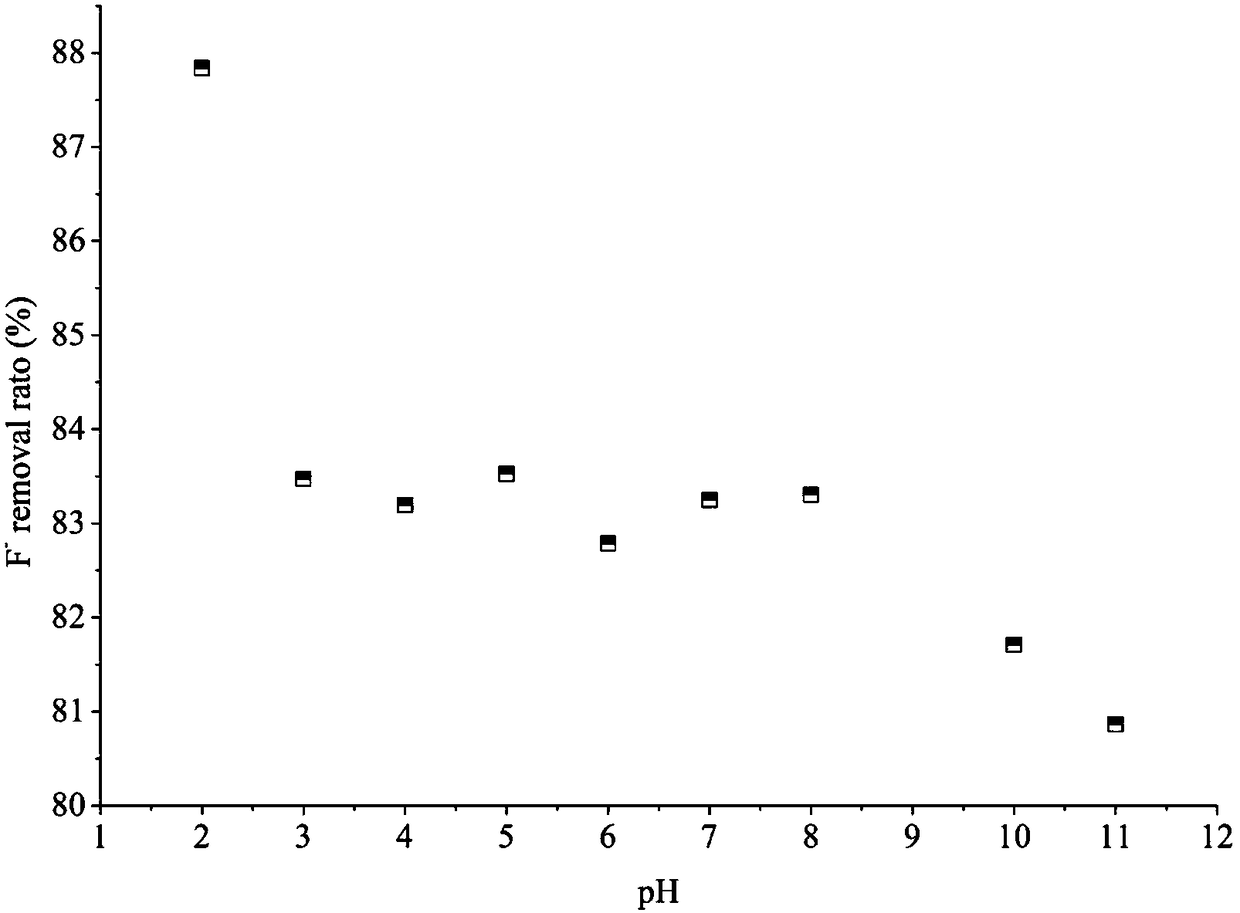

[0053] Such as image 3 Shown, the defluoridation effect of calcium-based adsorbent under different pH conditions. It can be seen from the figure that the calcium-based adsorbent can achieve a fluoride removal efficiency ...

Embodiment 3

[0055] The application of a calcium-based adsorbent for defluoridation in this embodiment in the treatment of fluorine product production wastewater:

[0056] Take the simulated fluorine product production wastewater, the fluorine concentration is 20mg / L.

[0057] A calcium-based adsorbent for defluoridation of the present embodiment and its application, the steps are:

[0058] (1) Take the calcined product of dolomite powder and fly ash with a weight ratio of 1.5:1 to synthesize, the synthesis temperature is 190° C., and the time is 6 hours to obtain a calcium-based adsorbent;

[0059] (2) Add calcium-based adsorbent to the waste water, the dosage is 1.25-25g / L, magnetically stir for 20min, centrifuge and separate the solid and water.

[0060] Such as Figure 4 As shown, the defluorination effect of the synthetic product under different dosage conditions: as can be seen from the figure, (without adjusting the pH value), when the dosage is 1.25g / L, the removal efficiency of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com