Preparation method of submicron Fe-Al-Mg composite metal oxide fluorine remover

A composite metal, sub-micron-level technology, applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., can solve problems such as imbalance of proportion, systemic fluorosis, joint disease, etc. The effect of low consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: First prepare 300 ml of a mixed solution of magnesium nitrate, magnesium nitrate and aluminum nitrate with a molar concentration of 0.1333 mol / L and continue to stir vigorously, then slowly add 200 ml of ammonia solution with a molar concentration of 1.8 mol / L to the above mixed solution After solution, keep stirring for 1 hour;

[0031] Step 2: Transfer the obtained brown-yellow suspension to a volumetric device, and leave it to age at room temperature for 12 hours;

[0032] Step 3: filter, wash, and dry the aged brown-yellow suspension, and keep it warm at 80°C for 12 hours to obtain a Fe-Al-Mg composite metal oxide defluorination agent.

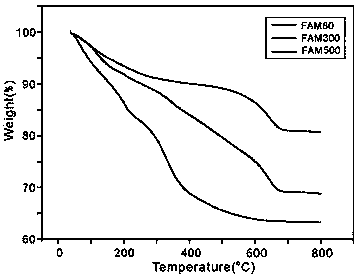

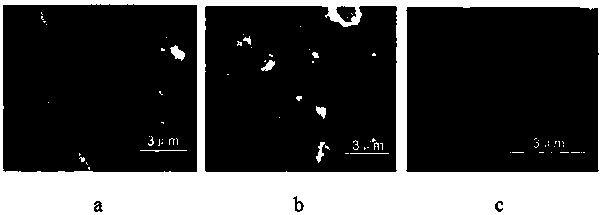

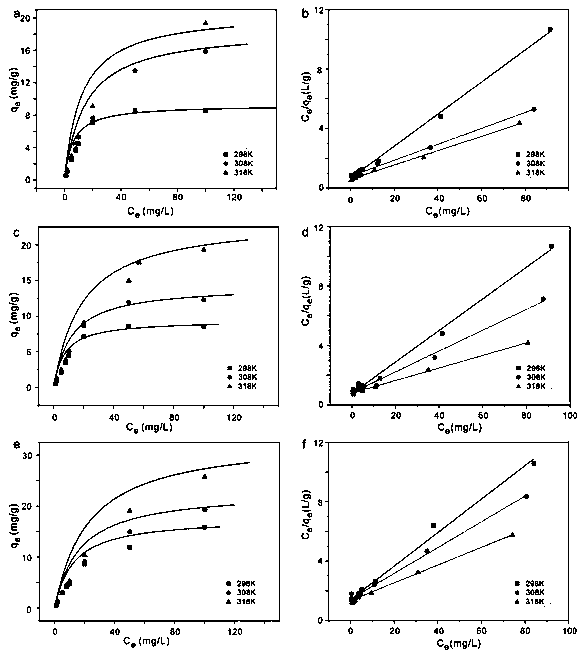

[0033] The above-mentioned Fe-Al-Mg composite metal oxide defluorination agent was characterized by scanning electron microscopy ( figure 1 a), it can be seen that it is a submicron structure, and its weight loss curve under high temperature conditions is obtained by a thermogravimetric analyzer ( image 3 ), using the Mic...

Embodiment 2

[0036] Step 1: First prepare 300 ml of a mixed solution of ferric chloride, magnesium chloride and aluminum chloride with a molar concentration of 0.1333 mol / L and continue to stir vigorously, then slowly add 200 mL of a sodium hydroxide solution with a molar concentration of 1.6 mol / L After reaching the above mixed solution, continue to stir for 1 hour;

[0037] Step 2: Transfer the obtained brown-yellow suspension to a volumetric device, and leave it to age at room temperature for 12 hours;

[0038] Step 3: After filtering, washing and drying the aged brown-yellow suspension, it was calcined and annealed at 300° C. for 4 hours to obtain a Fe-Al-Mg composite metal oxide defluorination agent.

[0039] The above-mentioned Fe-Al-Mg composite metal oxide defluorination agent was characterized by scanning electron microscopy ( figure 1 b), it can be seen that it is a submicron structure, and its weight loss curve under high temperature conditions is obtained by a thermogravimetri...

Embodiment 3

[0042] Step 1: First prepare 300 ml of magnesium nitrate, magnesium nitrate, and aluminum nitrate mixed solution with a molar concentration of 0.1333 mol / L and continue to stir vigorously, then slowly add 200 ml of potassium hydroxide solution with a molar concentration of 1.6 mol / L After reaching the above mixed solution, continue to stir for 1 hour;

[0043] Step 2: Transfer the obtained brown-yellow suspension to a volumetric device, and leave it to age at room temperature for 12 hours;

[0044] Step 3: Filter, wash, and dry the aged brown-yellow suspension, and calcine and anneal at 500°C for 4 hours to obtain a Fe-Al-Mg composite metal oxide defluorinating agent.

[0045] The above-mentioned Fe-Al-Mg composite metal oxide defluorination agent was characterized by scanning electron microscopy ( figure 1 c), it can be seen that it is a submicron structure, and its weight loss curve under high temperature conditions is obtained by a thermogravimetric analyzer ( image 3 ),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com