Three-dimensional oscillating high-energy ball mill

A high-energy ball mill, swing-type technology, applied in grain processing, etc., can solve problems such as inadaptability, and achieve the effect of adjusting vibration amplitude, solving bottom sinking, and novel and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

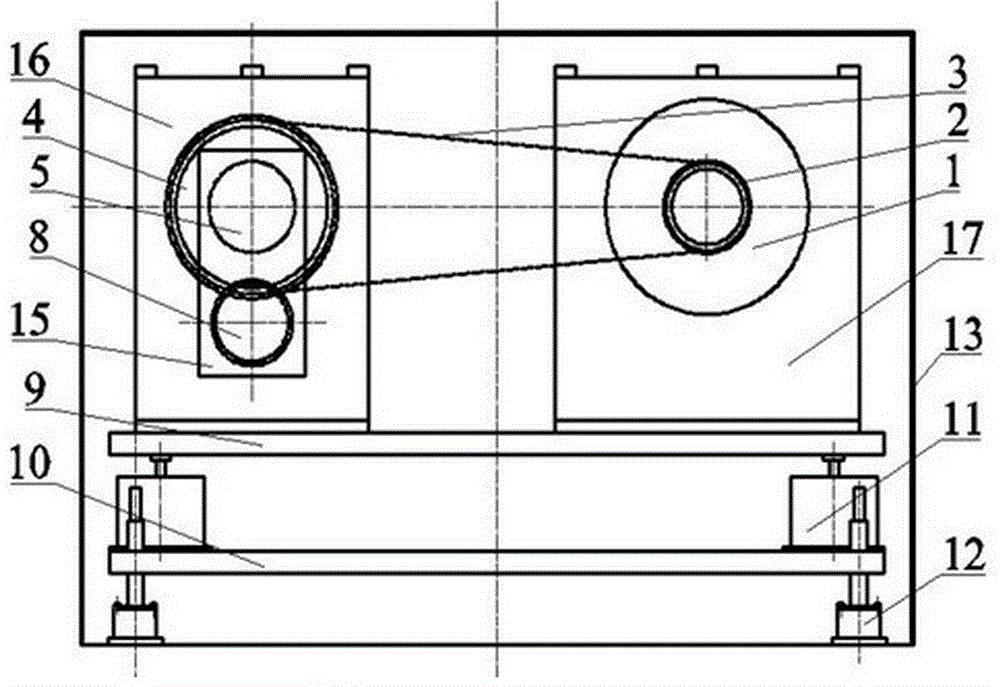

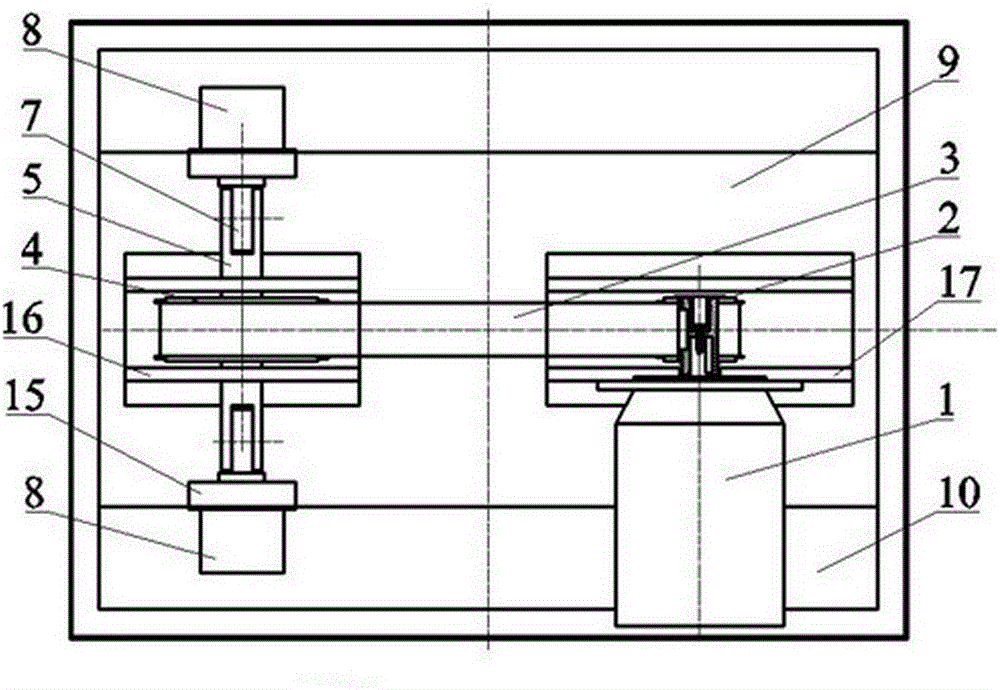

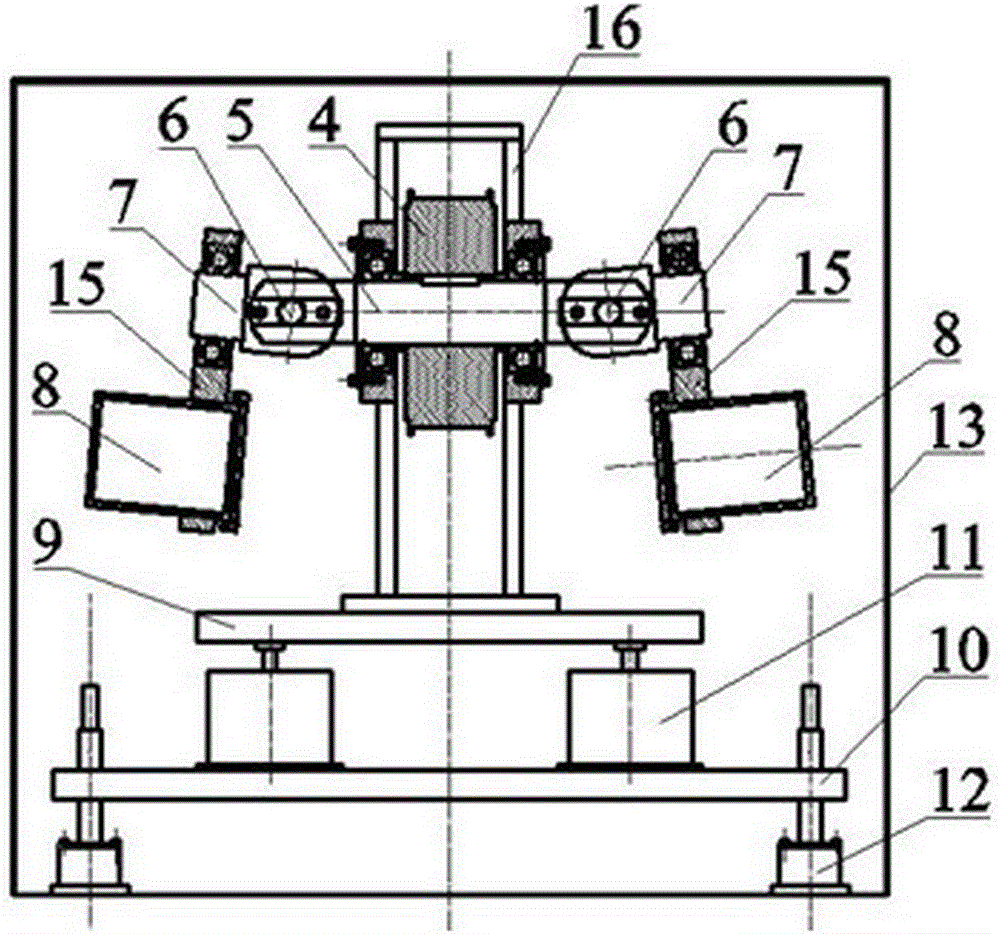

[0014] Example 1: Such as Figure 1-3 As shown, the composition of a three-dimensional swing high-energy ball mill is as follows:

[0015] The motor (1) is installed on the motor bracket (17), and the speed of the motor (1) is controlled by changing the output voltage using a frequency converter; multiple shock absorbers (11) are installed between the mounting plate (9) and the bottom plate (10) , the ball mill tank frame (15), the driven wheel bracket (16), and the motor bracket (17) are all installed on the mounting plate (9); Two adjustable feet (12) are installed on the bottom of the outer cover (13);

[0016] The driving wheel (2) of the motor (1) is installed on the shaft sleeve, and the driving wheel (2) is connected with the driven wheel (4) through the timing belt (3); the two bearing seats are installed on the two ends of the gantry bracket (16). On the stand plate, the driven shaft (5) passes through and is installed in the bearings in the two bearing seats, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com