Profile coal screening closed-conveying and reusing device

A technology for airtight transportation and briquette, which is applied in the direction of conveyor objects, transportation and packaging, and filter screens. It can solve the problems of motor vehicle wear and fuel consumption, high maintenance costs, and poor on-site environment, and achieve reduced consumption, less ash content, and particle size. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

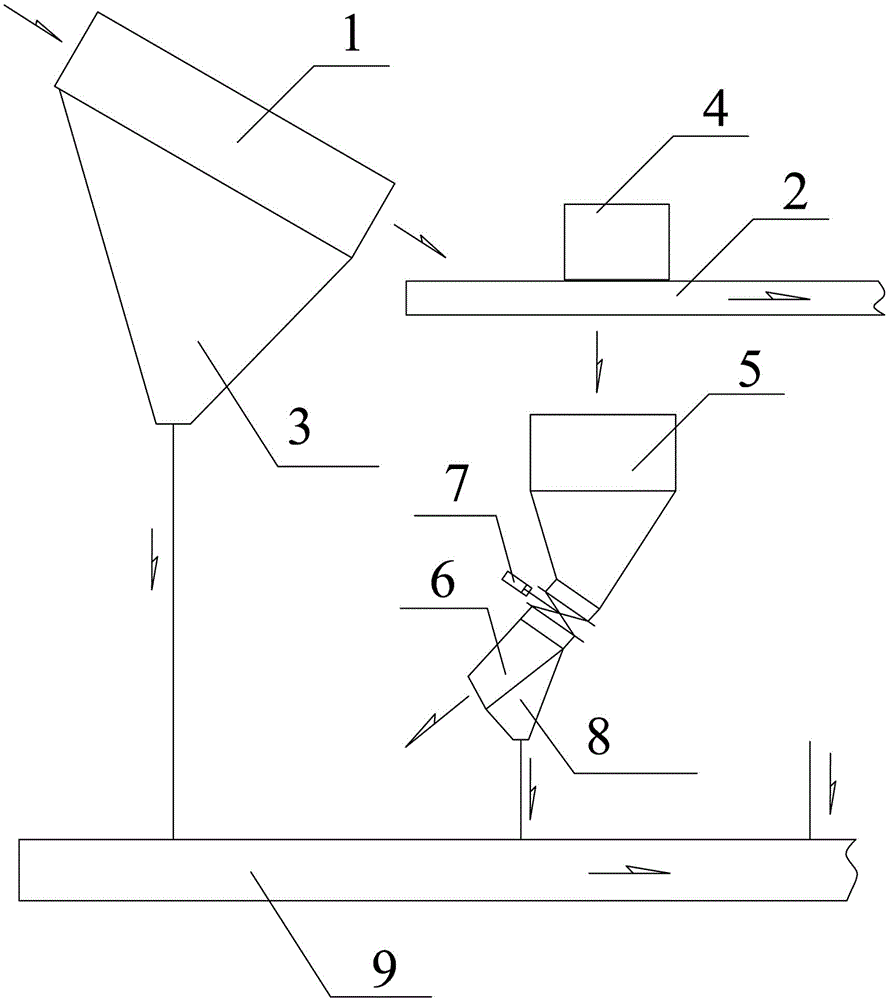

[0015] Such as figure 1 As shown, the present invention comprises vibrating screen 1, and the lower end outlet of vibrating screen 1 is provided with coal conveying belt conveyor 2, and the screen cloth below of moving screen 1 is provided with the first pulverized coal collecting bucket 3, and coal conveying belt conveyor 2 is equipped with The electric plow unloader 4 and the coal conveyor belt conveyor 2 are equipped with a silo 5 corresponding to the electric plow unloader 4. The outlet of the silo 5 is connected to the sieve 6, and the silo 5 is connected to the sieve 6. A plug valve 7 is installed at the bottom of the sliding screen 6, and a second pulverized coal collection bucket 8 is provided under the screen of the slide screen 6, wherein the outlets of the first pulverized coal collection bucket 3 and the second pulverized coal collection bucket 8 are connected to the buried scraper for conveying Machine 9.

[0016] The mesh spacing of the vibrating screen 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com