Vertical weld tracking system and method capable of adaptively adjusting inclination angle of welding gun

A technology of self-adaptive adjustment and tracking system, which is applied to the characteristics of welding electrodes, welding equipment, welding accessories, etc., can solve the problems of poor working environment, high labor intensity, and low quality of welding seam, so as to improve the quality of welding seam and welding. Efficiency, solving unsightly welding seam formation, and ensuring the effect of welding seam tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings

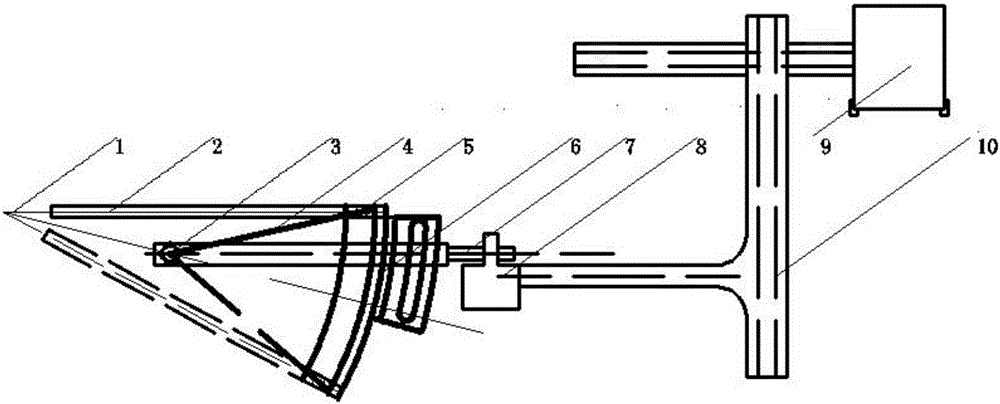

[0029] Please refer to the attached figure 1 In the figure, the structural welding wire 1; the welding torch 2; the swing motor 3; the swing shaft 4; the transmission slider 5; the sliding groove 6; the cross carriage attachment 7;

[0030] As shown in the picture:

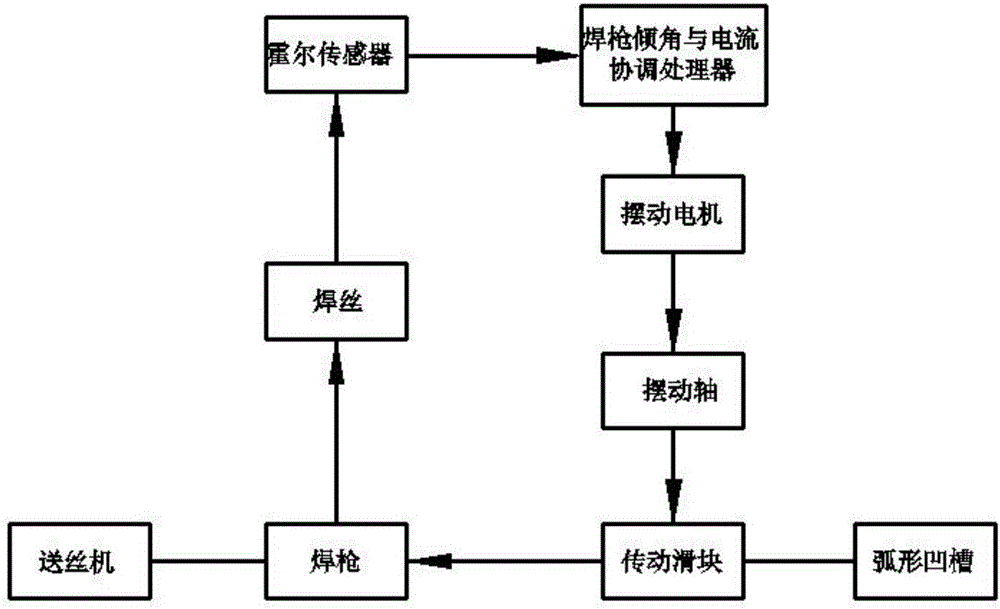

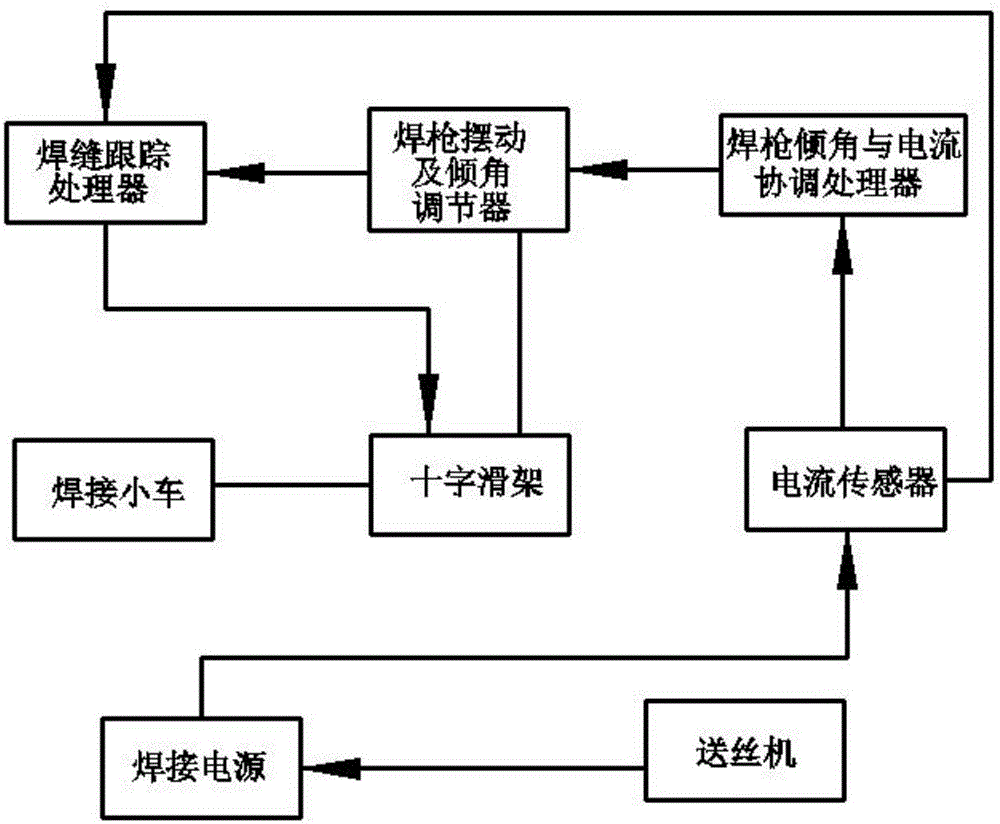

[0031] The present invention is a vertical welding seam tracking system and method for adaptively adjusting the inclination angle of the welding torch. The system mainly includes a current sensor, a welding torch swing and inclination angle regulator, a welding torch inclination angle and current coordination processor, a welding seam tracking processor, and a cross carriage , Welding trolley and components connecting circuit. The torch swing and inclination adjuster is installed on the welding cross carriage, the welding current signal is detected by the current sensor, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com