Pet toy, double-color forming module and double-color two-time vulcanization forming process

A secondary vulcanization and two-color molding technology, which is applied in the field of pet toys, can solve the problems of easy peeling off of adhesives, chaotic boundaries between two colors, weak adhesion of two colors, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

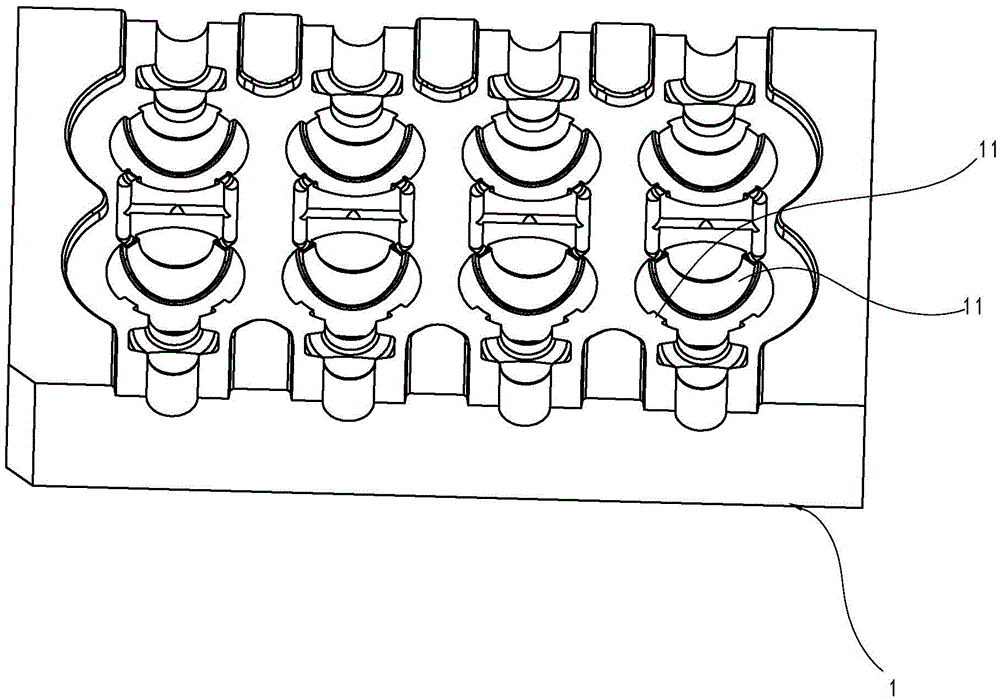

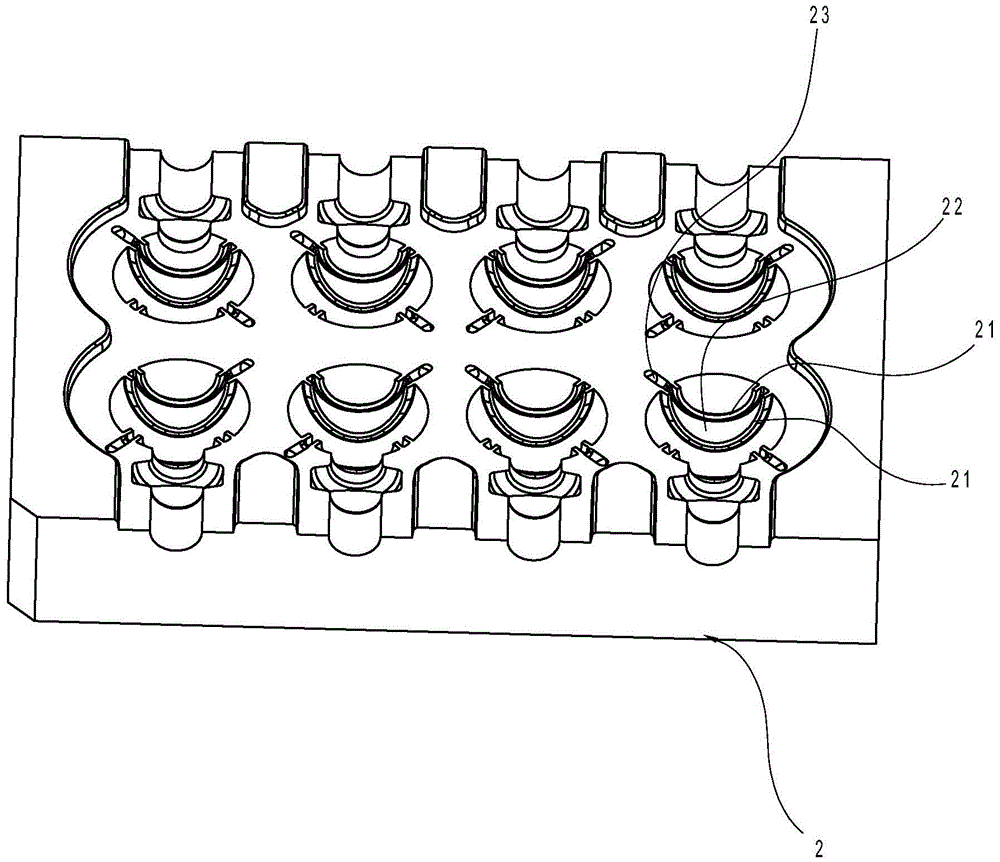

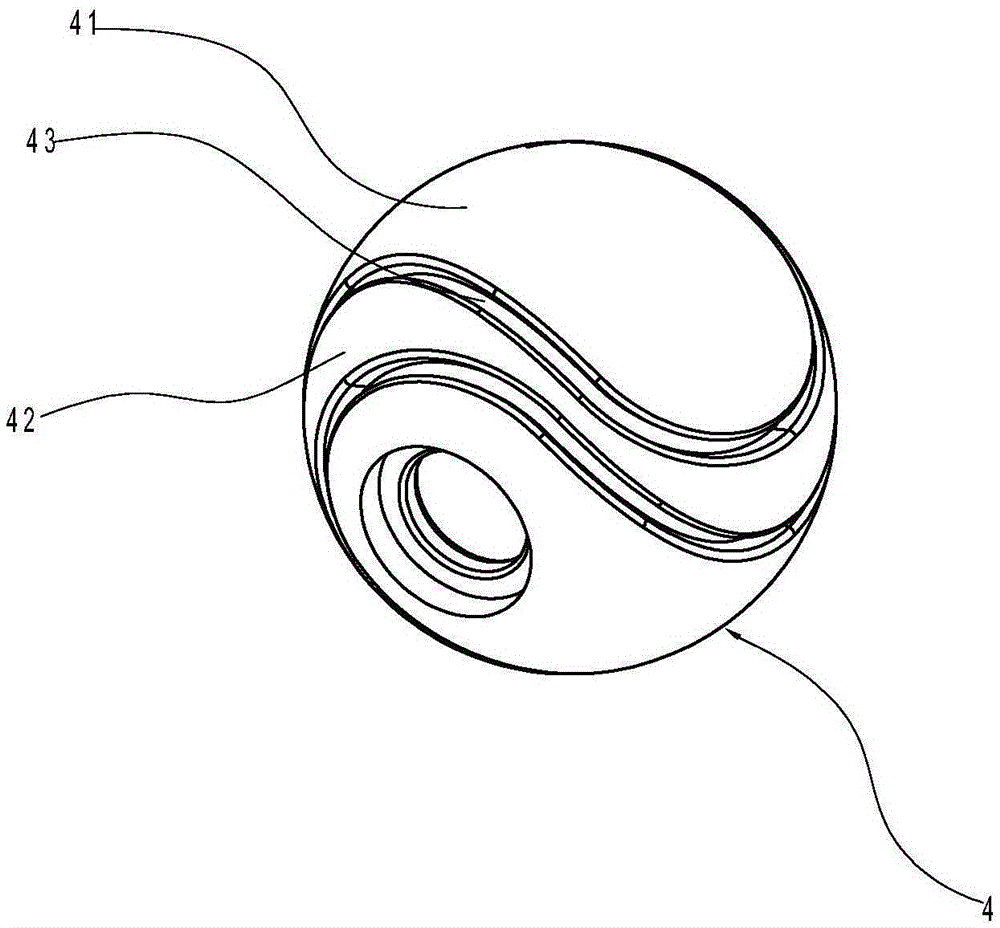

[0040]The pet toy of the present invention includes a base body 4 of a first color, the base body 4 is provided with a groove 43, and a stripe portion 42 of a second color protruding outward is formed in the groove 43. The stripe portion The bottom of the groove 42 and the bottom of the groove 43 are fused into an integral molded part, and there is a gap between the striped part 42 and the side wall of the groove 43 . There is a gap between the stripe portion 42 and the side wall of the groove 43. It can be that there is a gap between both sides of the stripe portion 42 and the side wall of the groove 43. It can also be a gap between one side of the stripe portion 42 and the groove 43. There is a gap in the side wall, and the other side blends with the side wall of the groove 43 . The pet toys in the present invention refer to various pet to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com