Graphite heat conducting foam and preparation process thereof

A technology of graphite heat conduction and foam, which is applied in the direction of lamination, layered products, metal layered products, etc., can solve the problem of easy shaking of graphite powder, achieve the effect of preventing leakage and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

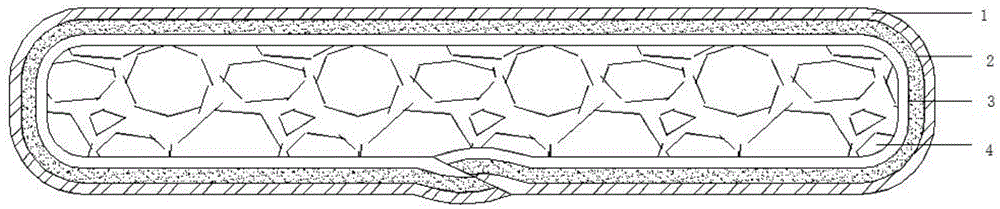

[0023] Embodiment 1 This embodiment discloses a graphite thermally conductive foam. The thermally conductive foam is composed of a copper foil layer 1, a graphite layer 2, a hot melt adhesive layer 3, and a metal sponge layer 4 that are sequentially wrapped from the outside to the inside;

[0024] The hot melt adhesive layer 3 is a double-sided tape; the copper foil layer 1 has a thickness of 0.01-0.1mm; the graphite layer 2 has a thickness of 0.01-0.5mm; the metal sponge layer 4 is a polyester sponge; The polyester sponge also contains copper or nickel.

Embodiment 2

[0025] Example 2 This example discloses a preparation process of a graphite thermally conductive foam (the product described in Example 1), and the process is as follows:

[0026] 1. First pass the graphite layer through a die-cutting machine to punch out the desired gap with a die-cutting machine according to different specifications; make its area smaller than the copper foil layer and the hot melt adhesive layer,

[0027] 2. Use a laminating machine to laminate the punched graphite layer with the copper foil layer to obtain a thermal conductive material;

[0028] 3. Then press the thermally conductive material composed of the graphite layer and the copper foil layer with the hot melt adhesive by heating and pressing; the pressing temperature is 140-180°C, and the pressing time is 1-2.5 seconds.

[0029] 4. Finally, wrap the finished graphite copper with a metal sponge, and use a forming machine to make the shape, and then slice it into use specifications by a slicer. After bonding, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com