Technique for coating film on paper surface

A technology of paper and film coating, applied in lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of film and paper separation, adhesion, difficult film and paper, etc., to improve the contact area and adhesion Increased, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

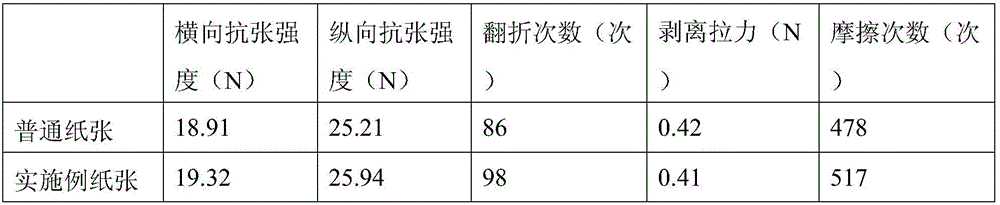

Embodiment 1

[0024] A paper surface coating process, which comprises the steps of:

[0025] Step 1: Install the upper and lower molds of the film-coated mold on the hydraulic press respectively;

[0026] Step 2: Take the paper coated with ink on the surface and place it on the lower mold at room temperature;

[0027] Step 3: Cover the ink in step 2 with an EVA film coated with polyvinyl alcohol, and keep the temperature at 100° C. for 1 hour;

[0028] Step 4: Keep the temperature and press down the upper mold, the pressing pressure is 0.3Kpa, and the time is 10s;

[0029] Step 5: Take out the paper, trim and complete the lamination.

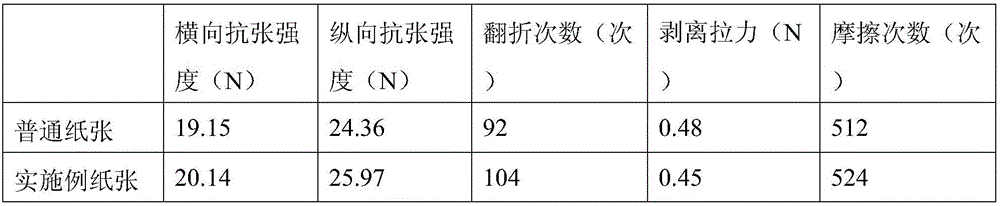

Embodiment 2

[0031] A paper surface coating process, which comprises the steps of:

[0032] Step 1: Install the upper and lower molds of the film-coated mold on the hydraulic press respectively;

[0033] Step 2: Take the paper coated with ink on the surface, and place it on the lower mold, where the temperature of the lower mold is 30°C, and the standing time is 25 minutes;

[0034] Step 3: Cover the EVA film coated with polyvinyl alcohol on the ink in step 2;

[0035] Step 4: press down on the upper mold;

[0036] Step 5: Take out the paper, trim and complete the lamination.

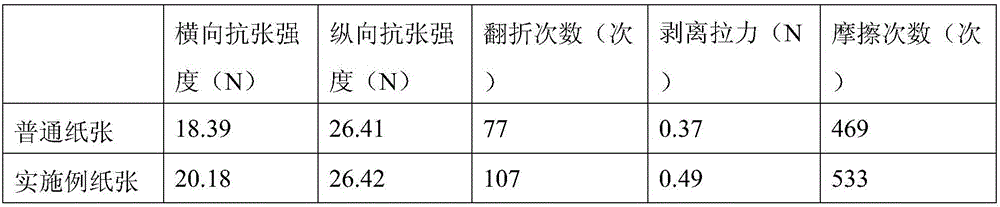

Embodiment 3

[0038] A paper surface coating process, which comprises the steps of:

[0039] Step 1: Install the upper and lower molds of the film-coated mold on the hydraulic press respectively;

[0040] Step 2: Take the paper coated with ink on the surface, and place it on the lower mold, where the temperature of the lower mold is 42°C, and the standing time is 23 minutes;

[0041] Step 3: Cover the ink in step 2 with an EVA film coated with polyvinyl alcohol, keep the temperature at 93°C for 1.7h;

[0042] Step 4: After reducing the temperature in step 3 to 8°C, the upper mold is pressed down at 0.4Kpa;

[0043] Step 5: Take out the paper, trim and complete the lamination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com