Liquid crystal film plating oil, preparation method and construction method thereof

A technology of coating oil and liquid crystal, applied in the direction of paint containing biocide, device for coating liquid on the surface, coating, etc. The effect of reducing viscosity and tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

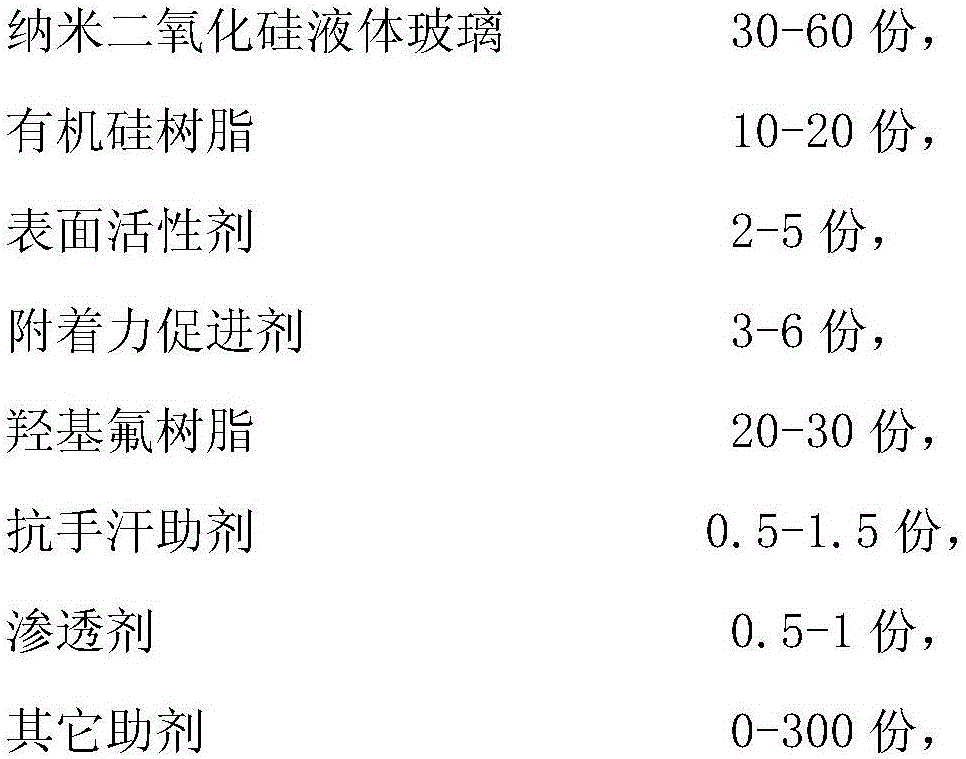

[0061] A general-purpose liquid crystal coating oil, comprising the following components by weight:

[0062]

[0063] The method for preparing general-purpose liquid crystal coating oil, comprises the following steps:

[0064] 1) Add nano-silica liquid glass, silicone resin, surfactant, adhesion promoter, hydroxyl fluororesin, anti-hand sweat additive, and penetrant into the dispersion cylinder in proportion;

[0065] 2) Disperse the material for 30 minutes at a speed of 600-800RPM. After dispersion, adjust the viscosity to 10 seconds (coat 4 cups) to obtain the finished product;

[0066] 3) Packing: Pack the finished products into standard translucent plastic containers and stick labels to obtain general-purpose liquid crystal coating oil.

[0067] The general-purpose liquid crystal coating liquid oil construction method comprises the following steps:

[0068] (1) base surface treatment

[0069] Clean the surface of the substrate with water or detergent. After the surfa...

Embodiment 2

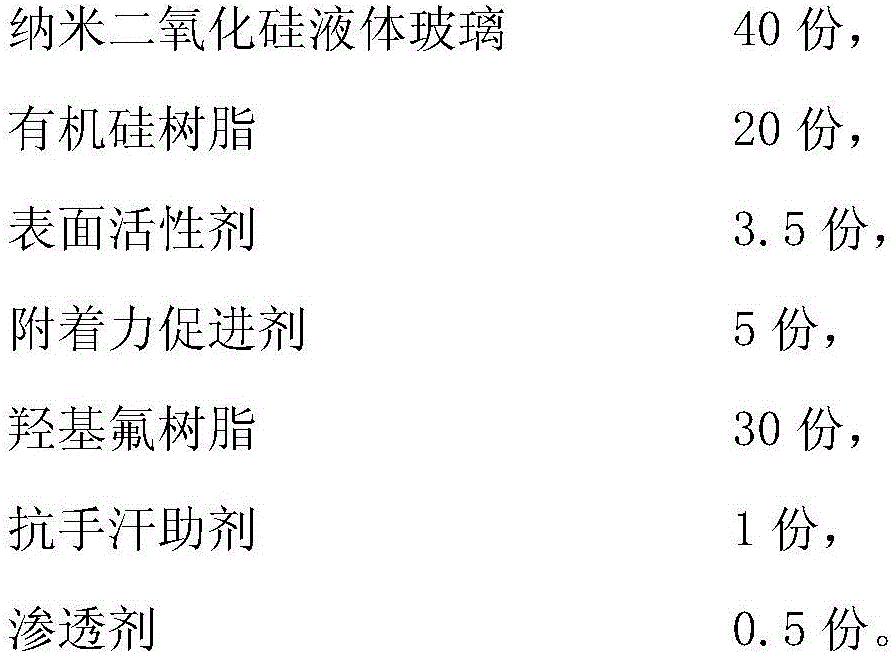

[0081] A protective liquid crystal coating oil, comprising the following components by weight:

[0082]

[0083]

[0084] The method for preparing protective liquid crystal coating oil comprises the following steps:

[0085] 1) Add nano-silica liquid glass, silicone resin, surfactant, adhesion promoter, hydroxyl fluororesin, anti-hand sweat additive, and penetrant into the dispersion cylinder in proportion;

[0086] 2) Disperse the material for 30 minutes at a speed of 600-800RPM. After dispersion, adjust the viscosity to 10 seconds (coat 4 cups) to obtain the finished product;

[0087] 3) Packaging: Pack the finished products into standard translucent plastic containers and stick labels to obtain protective liquid crystal coating oil.

[0088] The liquid oil construction method of protective liquid crystal coating comprises the following steps:

[0089] (1) base surface treatment

[0090] Clean the surface of the substrate with water or detergent. After the surface i...

Embodiment 3

[0101] A kind of decontamination type liquid crystal coating oil, comprises the following components by weight:

[0102]

[0103] The method for preparing decontamination type liquid crystal coating oil, comprises the following steps:

[0104] 1) Add nano-silica liquid glass, silicone resin, surfactant, adhesion promoter, hydroxyl fluororesin, anti-hand sweat additive, and penetrant into the dispersion cylinder in proportion;

[0105] 2) At a speed of 600-800RPM, disperse the material for 30 minutes. After the dispersion is complete, adjust the viscosity to 10 seconds (coat 4 cups) to prepare a semi-finished product;

[0106] 3) Add 300 parts of D-limonene to the semi-finished product in step 2), adjust the viscosity to 7 seconds (coat 4 cups), and make the finished product;

[0107] 4) Packing: Pack the finished products into standard translucent plastic containers and stick labels to obtain the decontamination liquid crystal coating oil.

[0108] The construction method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com