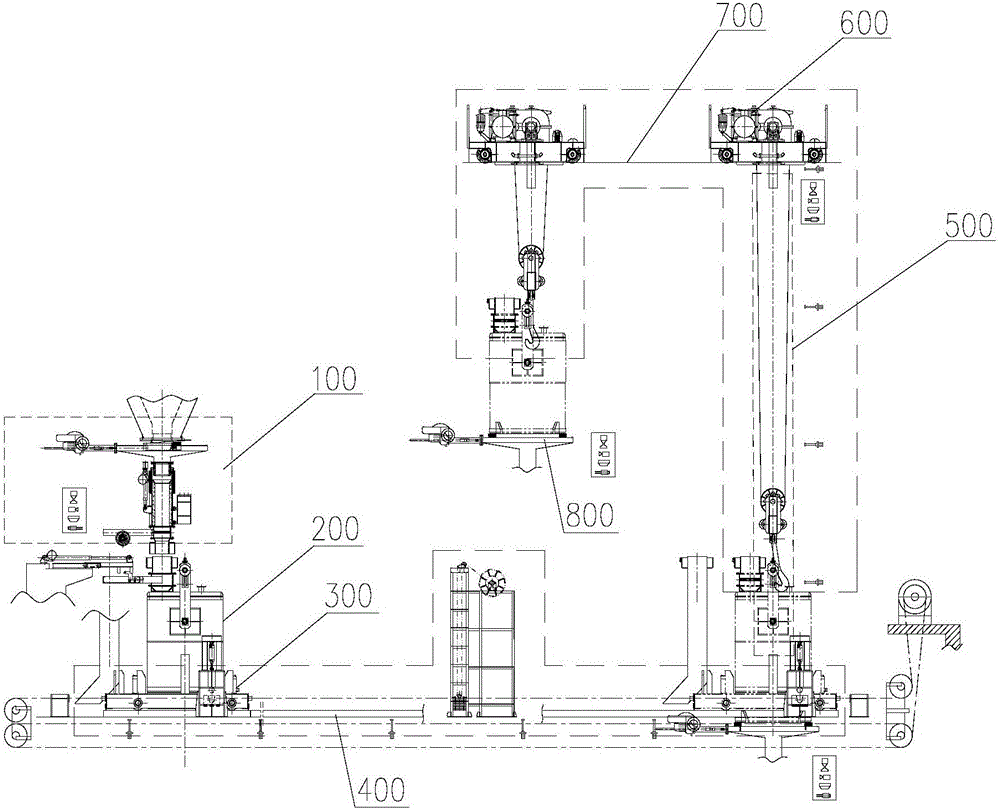

Loading tank shifting and transporting device

A technology for transfer devices and loading tanks, which is applied in the directions of transportation and packaging, loading/unloading, conveyors, etc., and can solve problems such as overload sensitivity, excessive loading, foreign matter jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

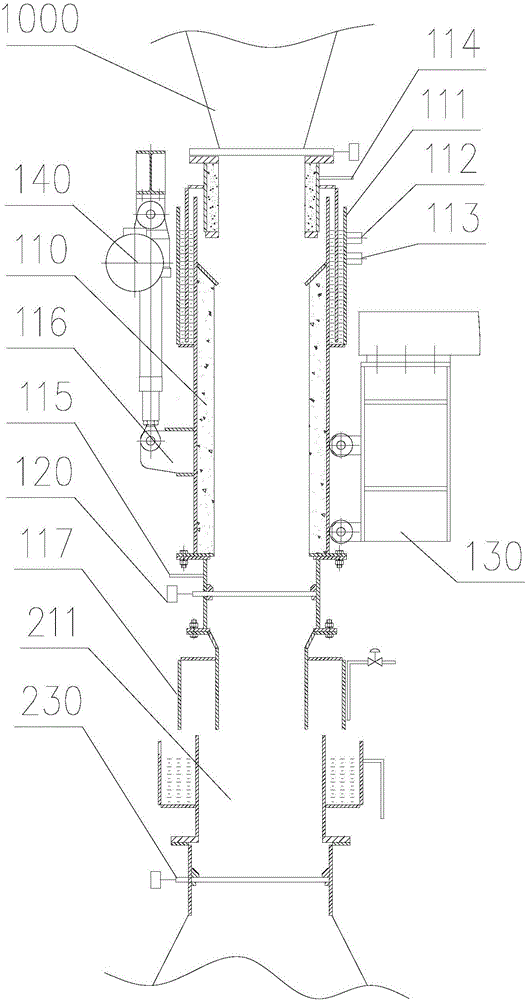

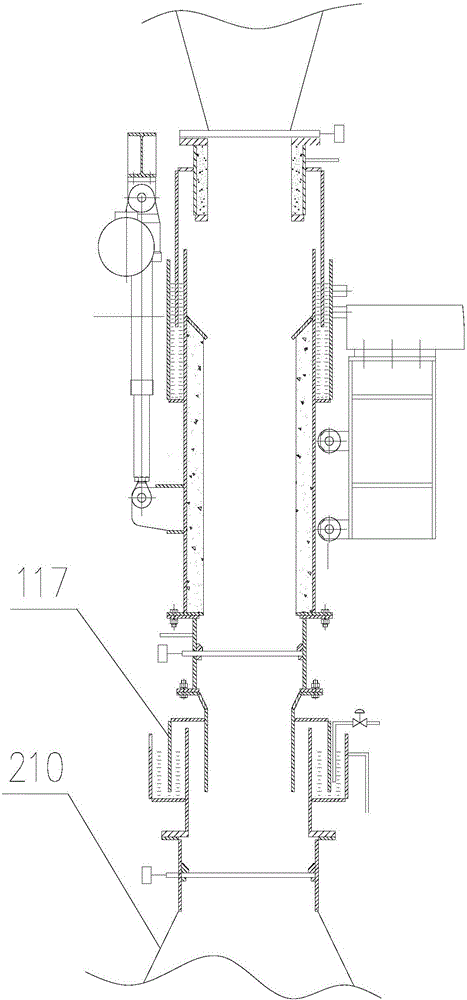

[0147] Embodiment 1: In the pyrolysis reaction system of the solid heat carrier coal graded refining of a set of coal handling capacity 3000 tons / day, adopted the above-mentioned material airtight conveying system of the present invention for its solid heat carrier (hot semi-coke) ) delivery. The high-temperature solid material in this example is hot semi-coke, the temperature of the material is 600°C, the particle size of the material is 6-25mm, the outer diameter of the tank is 1.7m, the height is 2.2m, the effective volume is 1.3m3, and the loading capacity is 600kg each time. , Combined with the weight of the equipment, the total weight is about 7 tons, that is, the weight of each transportation and lifting is about 7 tons. The loading tank with hot materials can be moved horizontally and lifted / lowered by hoisting and transferring tooling, realizing the cycle of hot semi-coke.

[0148] During operation, when the airtight transportation of high-temperature solid materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com