Method for recycling waste SCR denitration catalyst

A denitration catalyst and physical chemistry technology, applied in the field of recycling waste SCR denitration catalysts, can solve problems such as environmental pollution and waste of resources, achieve high economic and social benefits, and solve the effect of wasting land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

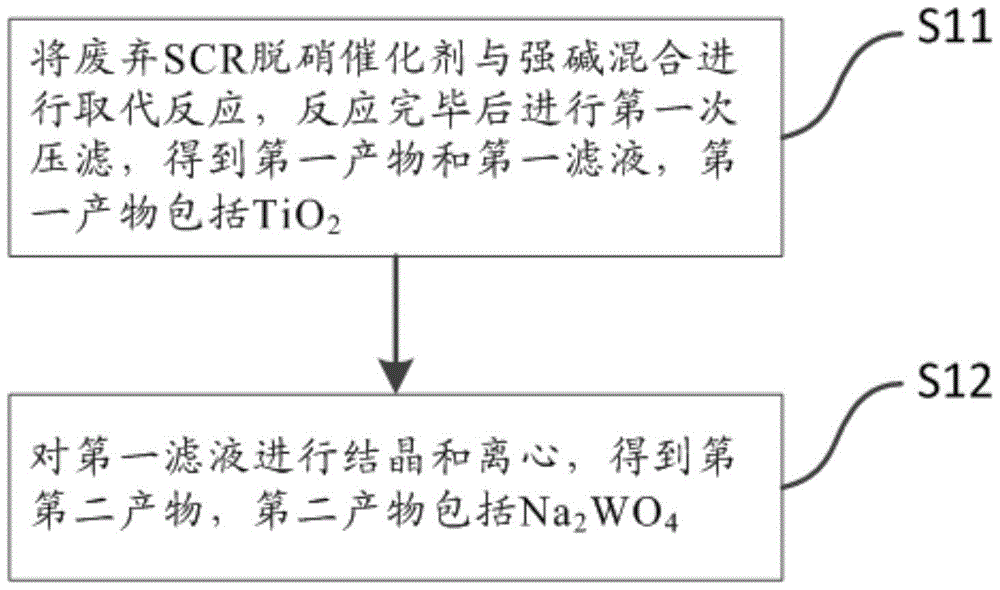

[0036] Such as figure 1 As shown, embodiment one provides a kind of method for recycling waste SCR denitration catalyst, comprising steps:

[0037] S11: Mix the waste SCR denitrification catalyst with a strong base for substitution reaction. After the reaction is completed, perform the first pressure filtration to obtain the first product and the first filtrate. The first product includes TiO 2 ;

[0038] S12: crystallize and centrifuge the first filtrate to obtain a second product, the second product includes Na 2 WO 4 .

Embodiment 2

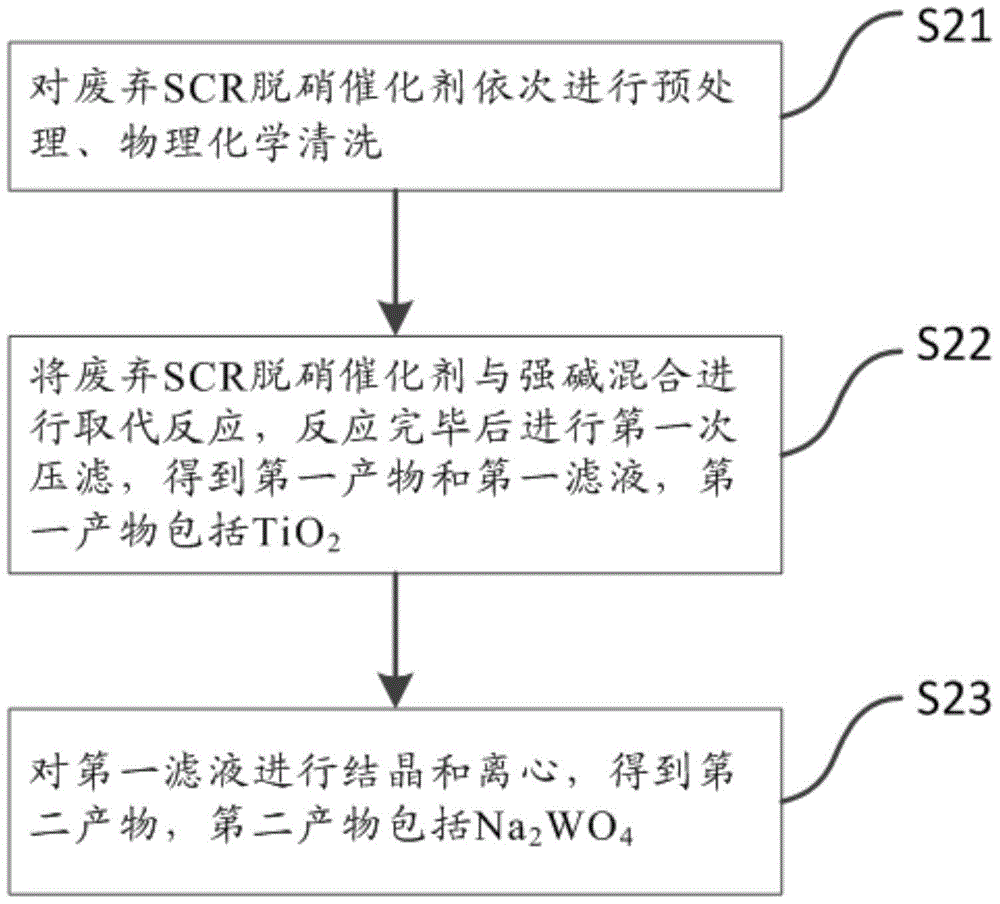

[0040] Such as figure 2 As shown, the method for recycling the waste SCR denitration catalyst in embodiment two comprises the following steps:

[0041] S21: Perform pretreatment and physical and chemical cleaning on the waste SCR denitration catalyst in sequence; specifically, after deashing and physical and chemical cleaning of the SCR denitration catalyst, the particle size of the SCR denitration catalyst is 45-55 μm, and when the particle size of the SCR denitration catalyst When the thickness is 50 μm, it is more conducive to the subsequent treatment of the SCR denitration catalyst;

[0042] S22: Mix the waste SCR denitrification catalyst with a strong base for substitution reaction. After the reaction is completed, perform the first pressure filtration to obtain the first product and the first filtrate. The first product includes TiO 2 ;

[0043] S23: crystallize and centrifuge the first filtrate to obtain a second product, the second product includes Na 2 WO 4 .

Embodiment 3

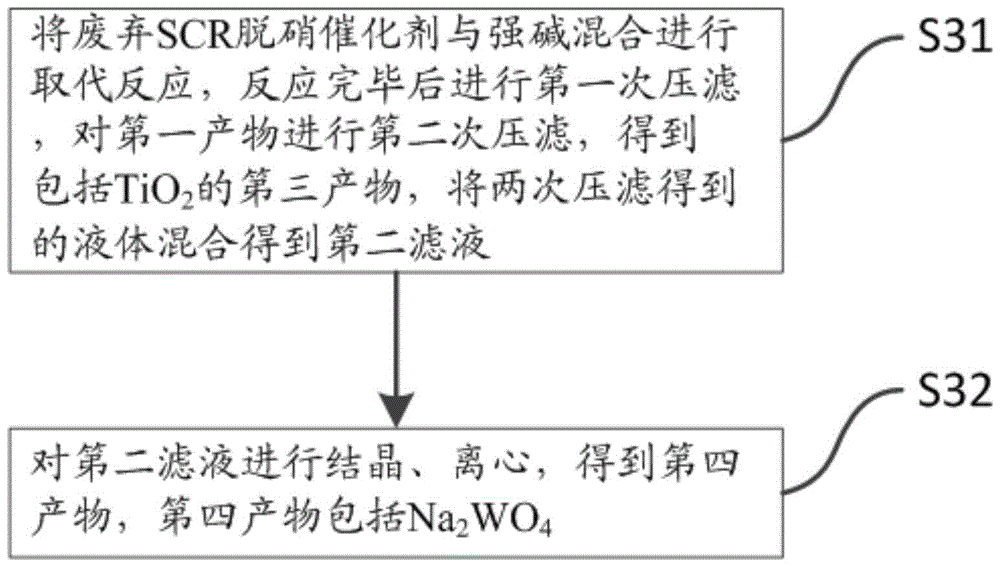

[0045] Such as image 3 As shown, the method for recycling the waste SCR denitration catalyst in embodiment three comprises steps:

[0046] S31: Mix the waste SCR denitrification catalyst with a strong base to perform a substitution reaction, perform a first pressure filtration after the reaction, and perform a second pressure filtration on the first product obtained by the first pressure filtration to obtain a third products, the third product includes TiO 2 , mixing the filtrate obtained by press filtration for the second time with the first filtrate obtained by press filtration for the first time to obtain a second filtrate;

[0047] S32: crystallize and centrifuge the second filtrate to obtain a fourth product, the fourth product includes Na 2 WO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com