System and method for preparing porcelain balls from chromium iron slag

A technology for ferrochromium slag and ceramic balls, applied in the field of metallurgical solid waste utilization, can solve the problems of ferrochromium slag to be improved, environmental pollution, occupation of land resources, etc., so as to save the fine grinding process, improve the working environment, and reduce dust pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

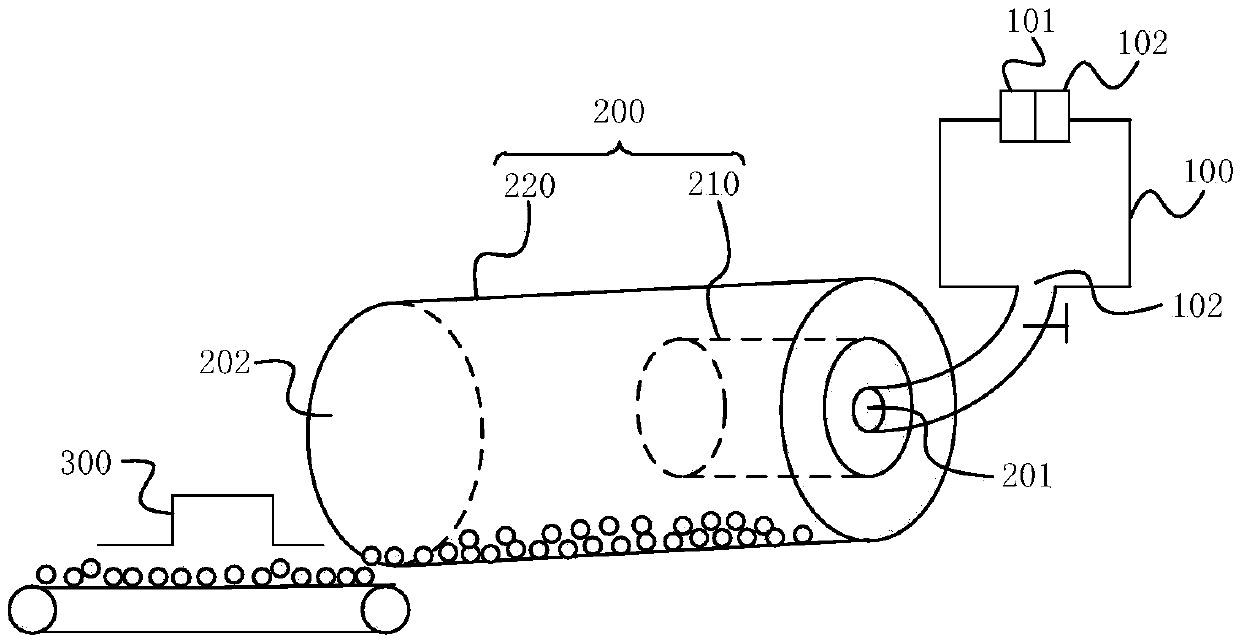

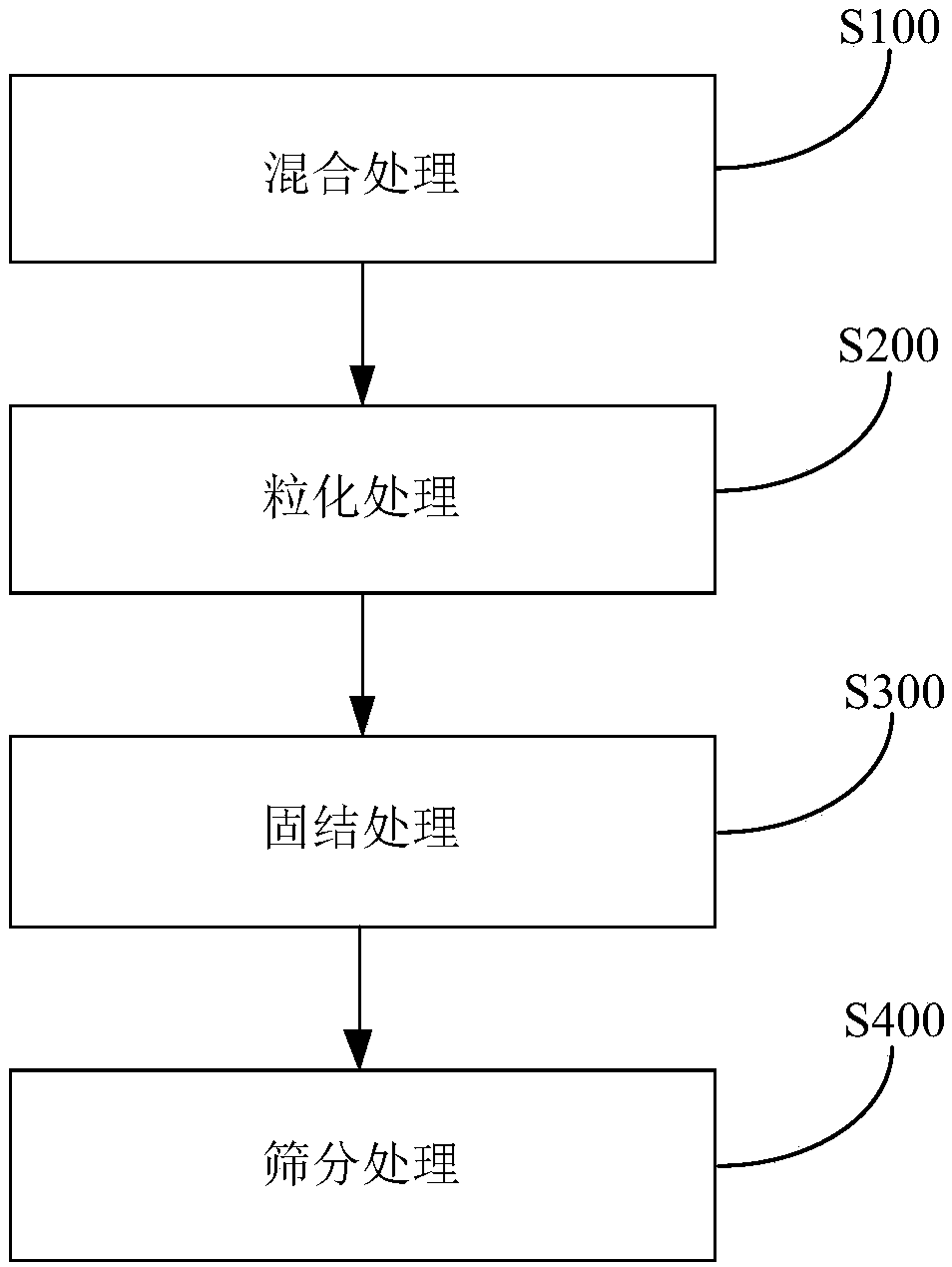

[0072] 1. Ferrochrome slag (Al 2 o 3 Content 40.0%, SiO 2 content 31.2%, MgO content 17.9%) into the middle holding electric furnace, with 30% Al 2 o 3 Alumina ceramic waste with a content of 91.3% keeps the slag in a molten state with good fluidity. The slag temperature is 1650-1700°C. Control the slag outlet flow valve of the intermediate heat preservation electric furnace to make the slag flow into the double-layer cylinder at a certain speed In the inner drum of the granulator.

[0073] 2. The inner drum rotates under the drive of the motor, and the slag is thrown away from the inner drum in a drop shape through the round hole on the drum under the combined force of centrifugal force, gravity, friction, etc., and the inner drum comes out. The diameter of the round hole on the arc surface of the material end is 5mm. During the falling process, the drop-shaped slag is in contact with the air to cool down to 1300-1400°C and solidifies on the surface, falls into the outer...

Embodiment 2

[0077] 1. Ferrochrome slag (Al 2 o 3 Content 23.3%, SiO 2 content 39.6%, MgO content 25.3%) into the middle holding electric furnace, with 45% Al2 o 3 A mixture of alumina ceramic ball waste and ceramic waste with a content of 84.6% in any proportion. Keep the slag in a molten state with good fluidity. The slag temperature is 1700-1750°C. Control the slag outlet flow valve of the intermediate heat preservation electric furnace to make the slag flow into the inner drum of the double-layer cylindrical granulator at a certain speed.

[0078] 2. The inner drum rotates under the drive of the motor, and the slag is thrown away from the inner drum in a drop shape through the round hole on the drum under the combined force of centrifugal force, gravity, friction, etc., and the inner drum comes out. The diameter of the round hole on the arc surface of the material end is 6mm. During the falling process, the drop-shaped slag is in contact with the air to cool down to 1300-1400°C and...

Embodiment 3

[0082] 1. Ferrochrome slag (Al 2 o 3 Content 32.1%, SiO 2 content 22.6%, MgO content 25.2%) into the middle holding electric furnace, with 60% Al 2 o 3 The alumina castable waste with a content of 93.2% keeps the slag in a molten state with good fluidity. The slag temperature is 1750-1800°C. Control the slag outlet flow valve of the intermediate heat preservation electric furnace to make the slag flow into the double-layer circle at a certain speed. In the inner drum of the drum granulator.

[0083] 2. The inner drum rotates under the drive of the motor, and the slag is thrown away from the inner drum in a drop shape through the round hole on the drum under the combined force of centrifugal force, gravity, friction, etc., and the inner drum comes out. The diameter of the round hole on the arc surface of the material end is 8mm. During the falling process, the drop-shaped slag contacts with the air to cool down to 1200-1400°C and solidifies on the surface, falls into the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com