High-nitrogen forest base fertilizer and production method thereof

A technology for forest trees and base fertilizers, applied in nitrogen fertilizer, potash fertilizer, phosphate fertilizer and other directions, can solve the problems of polluted groundwater, irreversible degradation of cultivated land, high water content, reduce environmental harm, and solve the effect of difficult promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

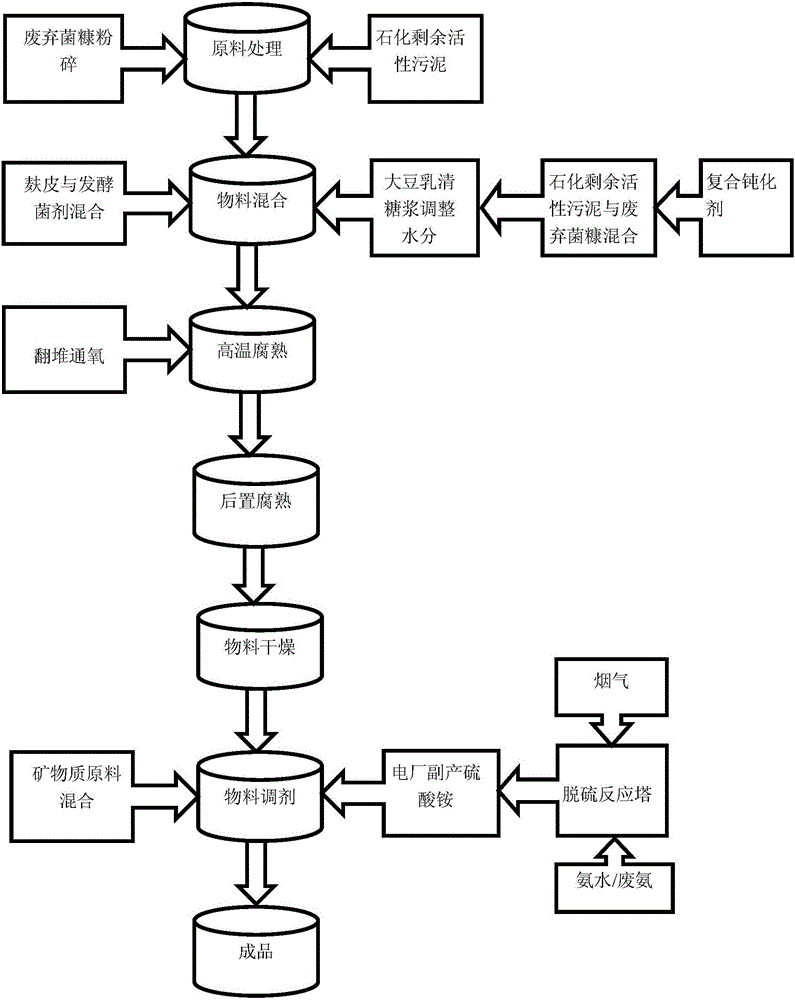

Method used

Image

Examples

Embodiment 1

[0040] A kind of high-nitrogen forest tree base fertilizer, its raw material is composed of: 40% of petrochemical residual activated sludge, 20% of ammonium sulfate by-product of power plant, 25% of waste fungus chaff, 2.5% of compound passivator, soybean whey syrup 10%, bran 0.5%, fermentation agent 0.2% and mineral raw material 1.8%.

[0041] The composite passivating agent, in terms of mass percentage, is composed of raw materials: 20% of fly ash, 55% of zeolite powder, and 25% of rice bran powder.

[0042] The mineral raw material is a mixture of phosphorus fertilizer and potassium fertilizer, and the mass ratio of phosphorus fertilizer to potassium fertilizer is 1:1.8.

[0043] The phosphate fertilizer is superphosphate; the potassium fertilizer is potassium sulfate.

[0044] The production method of described high-nitrogen tree base fertilizer, its concrete steps are:

[0045] (0) Prepare raw materials and take each raw material in proportion, for subsequent use;

[0...

Embodiment 2

[0053] A high-nitrogen tree-based fertilizer. The raw materials are composed of 60% of petrochemical residual activated sludge, 22% of by-product ammonium sulfate from power plants, 10% of waste fungus chaff, 1.55% of compound passivator, and soybean whey syrup in terms of mass percentage. 3.4%, bran 2%, fermentation agent 0.05% and mineral raw material 1%.

[0054] The composite passivator is calculated by mass percentage, and its raw materials are composed of 40% of fly ash, 45% of zeolite powder and 15% of rice bran powder.

[0055] The mineral raw material is a mixture of phosphorus fertilizer and potassium fertilizer, and the mass ratio of phosphorus fertilizer to potassium fertilizer is 1:2.0.

[0056] The phosphate fertilizer is calcium magnesium phosphate fertilizer; the potassium fertilizer is potassium chloride.

[0057] The production method of described high-nitrogen tree base fertilizer, its concrete steps are:

[0058] (0) Prepare raw materials and take each ra...

Embodiment 3

[0066] A high-nitrogen tree-based fertilizer. The raw materials are composed of 50% of petrochemical residual activated sludge, 15% of ammonium sulfate by-product of power plant, 25% of waste fungus chaff, 2.5% of compound passivator, and soybean whey syrup in terms of mass percentage. 2.9%, bran 2%, fermentation agent 0.1% and mineral raw material 2.5%.

[0067] The composite passivator, in terms of mass percentage, is composed of raw materials: 30% of fly ash, 65% of zeolite powder, and 5% of rice bran powder.

[0068] The mineral raw material is a mixture of phosphorus fertilizer and potassium fertilizer, and the mass ratio of phosphorus fertilizer to potassium fertilizer is 1:3.0.

[0069] The phosphate fertilizer is phosphate rock powder; the potassium fertilizer is potassium sulfate.

[0070] The production method of described high-nitrogen tree base fertilizer, its concrete steps are:

[0071] (0) Prepare raw materials and take each raw material in proportion, for sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com