Full tailings stacking method for overburden layer under transition from open-pit to underground pillarless sublevel caving method

A segmental caving method, open-pit to underground technology, applied in the field of open-pit to underground sub-pillar caving method covering layer full tailings stacking, can solve the problem of insufficient storage capacity of mine tailings storage, achieve mechanical properties up to standard, The effect of prolonging the service life and water retention and flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

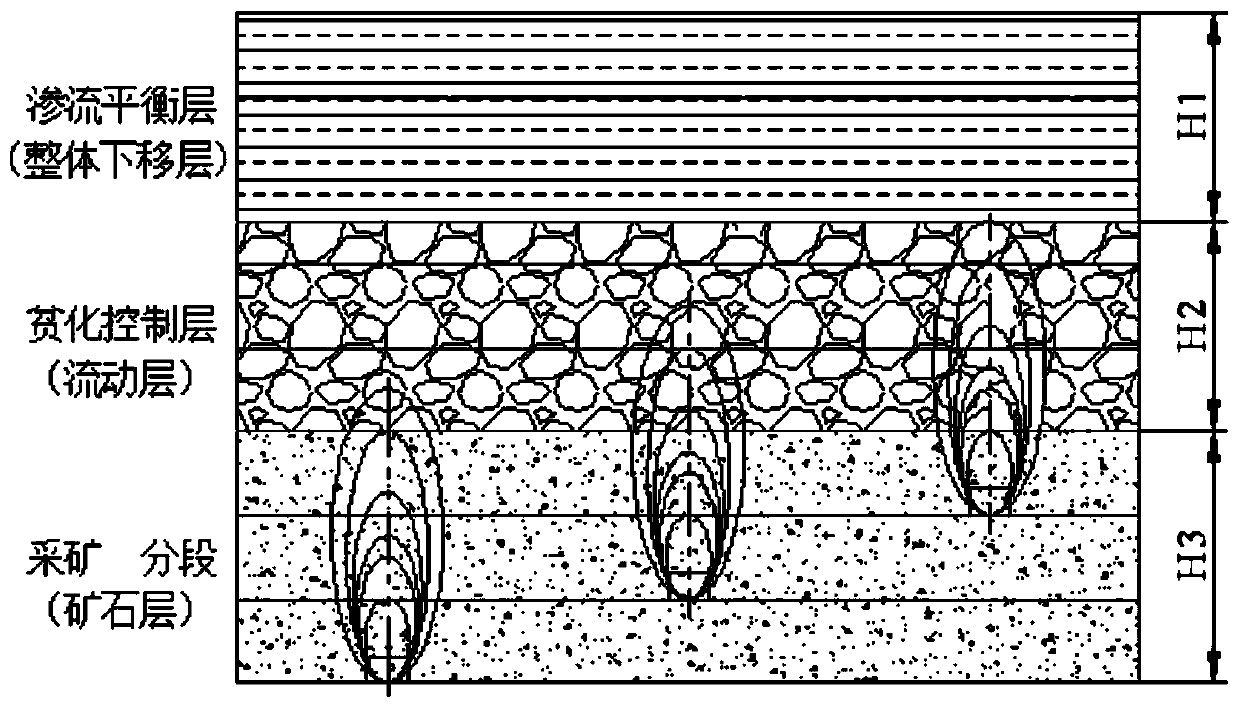

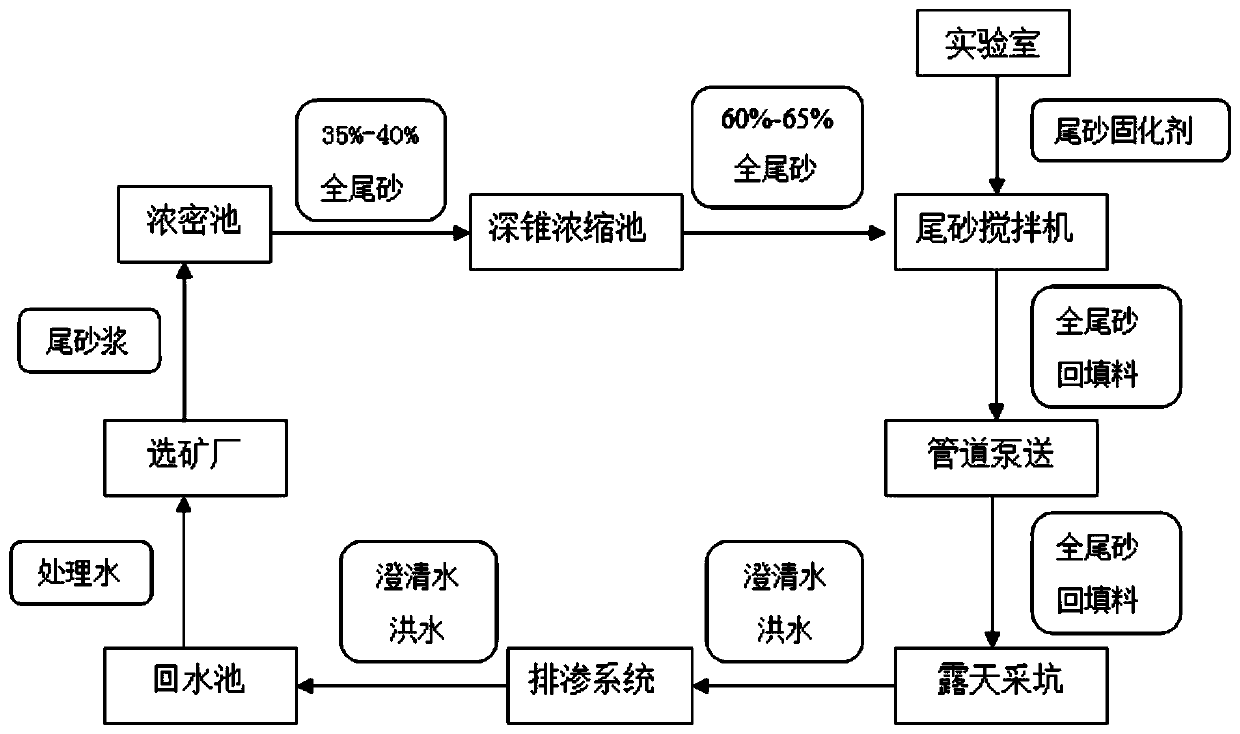

[0045] The invention provides a method for stacking full tailings in the overburden of the open-pit to underground pillar-less subsection caving method. The process is as follows figure 2 As shown, the specific steps are as follows:

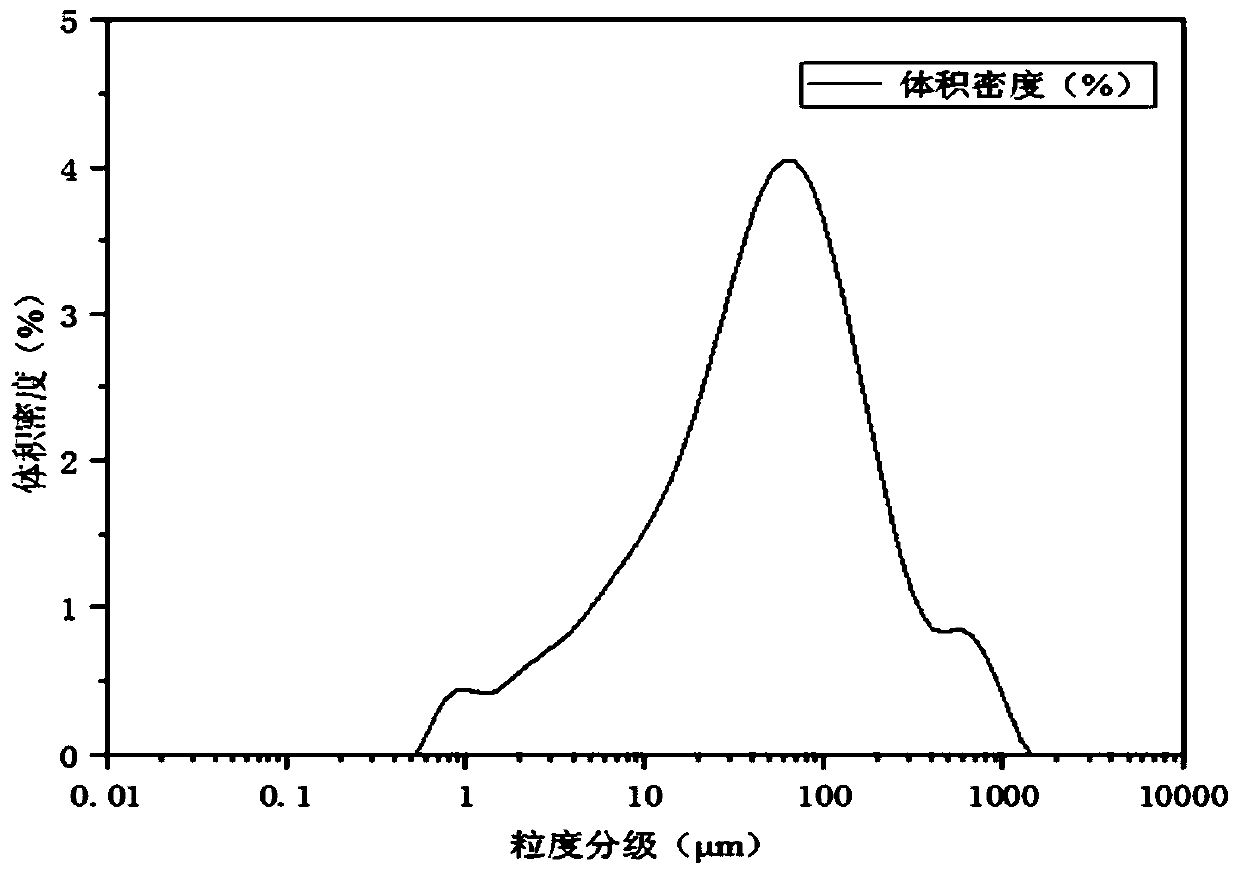

[0046] 1. Detection and analysis of the whole tailings flowing out of the dense pool bottom of an iron ore plant. The detection and analysis content includes tailings particle size, mineral composition, mineral content, natural settlement, and natural accumulation; the mineral composition of iron tailings is shown in Table 1. , particle size such as image 3 Shown:

[0047] Table 1 Analysis results of the whole tailings of an iron ore (%)

[0048]

[0049] Pipeline Requirements:

[0050] ①The basic requirement of slurry particle size composition is that the content of -20μm is not less than 15%. Sand-20μm content 15%-20%, meet the requirements;

[0051] ② The slump range of gravity conveying slurry is 23-27cm, (in this embodiment, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com