Method for continuously stoping water-containing tailings

A technology of mine tailings and water tailings, which is applied in mineral mining, special mining, earth square drilling, etc. It can solve the problems of high water content, inability to achieve recovery, and inability to achieve large-scale continuous mining, etc., to achieve strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for continuously mining water-containing tailings, comprising the steps of:

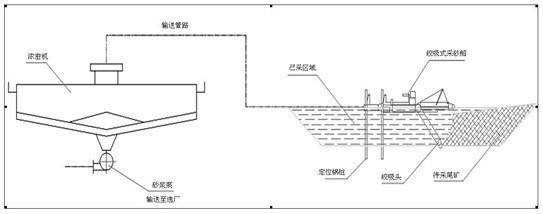

[0028] S1: The determination of the sand mining ship and the division of the mining zone. According to the characteristics of finer and more uniform tailings, the type of sand mining ship selected in this plan is the cutter suction type, and the amount of tailings mined by the sand mining ship is a constant. The amount of tailings to be mined is determined according to the daily processing capacity of the concentrator, and the 10% over-extraction is considered, which can ensure the reliability of the selection of equipment. The width of the mining zone is 1.2-1.4 times the length of the cutter suction sand dredger. The division is mainly based on the working principle of the cutter suction sand mining ship. The cutter suction sand mining ship uses two steel piles inserted into the bottom as the swing center, and uses the alternate retraction and retraction of the left and right swing c...

Embodiment 2

[0033] A method for continuous mining of water-containing tailings. The invention is applied to a tailings comprehensive utilization project of a mining company. The project site belongs to the natural hilly area on the continental edge of the Gulf. The tailings pond is located in a natural depression basin terrain. The mine adopts the tailings after magnetic separation, and the tailings are enriched to a certain extent in the useful components such as copper and sulfur in the ore after iron separation, which meets the requirements of industrial utilization. After the exploration of the tailings pond, the metal The content of copper is between 0.3-0.5%, which has a high recovery value.

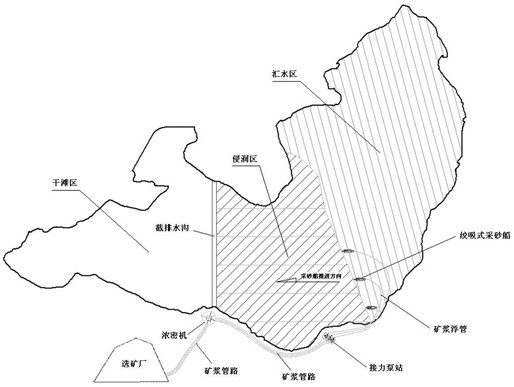

[0034] The tailings pond is about 3km long from east to west and about 1km wide from north to south. From east to west, it forms dry beach area, infiltration area and water catchment area. Due to the humid local air and the natural terrain of the tailings pond, there are no engineering faciliti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com