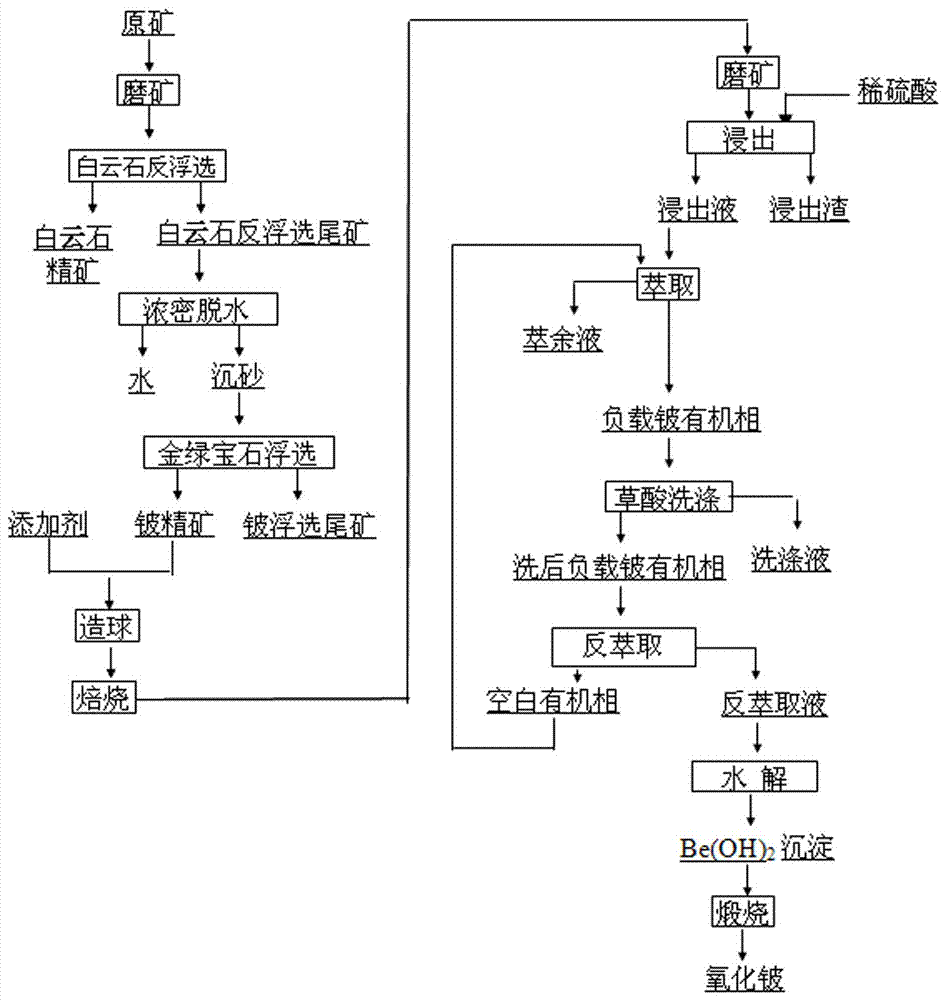

A combined dressing and metallurgy method for extracting beryllium oxide from chrysoberyl beryllium ore

A combined technology of chrysoberyl, beneficiation and smelting, applied in the direction of chemical instruments and methods, wet separation, process efficiency improvement, etc., can solve the problem of beryllium concentrate that does not meet the requirements of beryllium smelting, cannot adapt to the production process, and concentrate grade Low-level problems, to achieve the effect of increasing strength, reducing roasting time, and lowering roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The chrysoberyl beryllium ore containing 0.59% BeO is ground to 0.074mm, accounting for 98%, adding 12Kg / t of water glass, stirring for 5 minutes, adding 1.2Kg / t of oxidized paraffin wax soap, stirring for 3 minutes, and performing dolomite reverse flotation Election; the dolomite roughing concentrate is subjected to two selections: the first selection does not add chemicals, stirring for 3 minutes; the second selection, adding water glass 2Kg / t, stirring for 3 minutes, and roughing the dolomite The dolomite flotation tailings combined with the tailings and the secondary beneficiation tailings are left to stand naturally for 1 hour, the overflow water in the upper layer is pumped out, and the lower layer is the precipitated grit; add aluminum sulfate 1.33Kg / t to the grit, and stir for 3 minutes , add sodium fluorosilicate 5.33Kg / t, stir for 5 minutes, add Thal soap 1.33Kg / t, oxidized paraffin soap 0.72Kg / t, stir for 3 minutes, carry out a rough separation, add Thal to th...

Embodiment 2

[0019]Chrysoberyl beryllium ore containing 0.40% BeO is ground to -0.074mm, accounting for 97%, adding water glass 8Kg / t, stirring for 5 minutes, modified oleic acid 0.6Kg / t, stirring for 3 minutes, and performing dolomite reverse flotation Rough selection; two selections are carried out on the dolomite rough selection concentrate: the first selection does not add chemicals, stirring for 3 minutes; the second selection adds water glass 2Kg / t, stirring for 5 minutes; the dolomite rough selection The dolomite flotation tailings combined with the tailings and the secondary beneficiation tailings are naturally precipitated for 1 hour, the upper layer overflow water is pumped out, and the lower layer is sand settling; add aluminum sulfate 1.5Kg / t to the sand settling, and stir for 3 minutes; add fluorine Sodium silicate 5Kg / t, stirring for 5 minutes; adding Tal soap 1.2Kg / t, modified oleic acid 0.6Kg / t, stirring for 3 minutes, performing a rough separation, and adding Tal soap 0.4Kg...

Embodiment 3

[0021] Chrysoberyl ore containing 0.245% BeO is ground to -0.074mm, accounting for 98%, adding water glass 6Kg / t, stirring for 5 minutes, oxidized paraffin wax soap 0.7Kg / t, stirring for 3 minutes, and performing dolomite reverse flotation roughing , carry out two selections on the dolomite roughing concentrate: the first selection without adding chemicals, stirring for 3 minutes; the second selection adding water glass 1Kg / t, stirring for 5 minutes; the dolomite roughing tailings The dolomite flotation tailings combined with the secondary beneficiation tailings are naturally precipitated for 1 hour, the upper layer overflow water is removed, and the lower layer is sand settling; add aluminum sulfate 0.9Kg / t to the sand settling, and stir for 3 minutes; add fluorosilicic acid Sodium 1.3Kg / t, stirring for 5 minutes; adding 335g / t of tall soap and 170g / t of oxidized paraffin wax soap, stirring for 3 minutes, and performing a rough separation, and adding 170g / t of tall soap to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com