Adsorption treatment process for harmful substances in cooking pot

A technology for harmful substances and adsorption treatment, applied in the field of kitchen utensils, can solve the problems of excessive heavy metal content and great harm, and achieve the effects of improved adsorption effect, good adhesion performance, and accelerated slag accumulation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

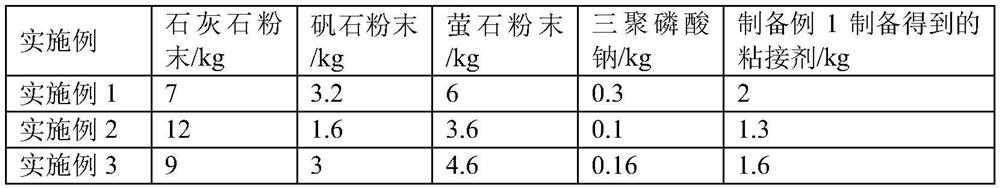

Examples

preparation example 1

[0039] The boronite is crushed and ground, and the ground boronite crosses 30 and 40 mesh sieves to obtain the boronite powder, and takes by weighing 1kg boronite powder, 30kg water glass and 6kg zeolite particles (selecting 1-5mm particle diameter) Zeolite particles) were put into 20L of water, stirred and mixed evenly at room temperature to obtain a mixture, and the mixture was dried by a spray drying tower to obtain an adhesive.

preparation example 2-3

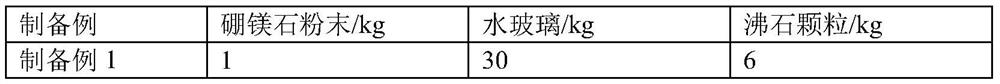

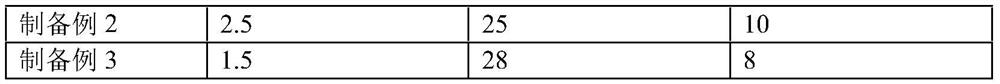

[0040] The difference between Preparation Example 2-3 and Preparation Example 1 is that the additions of boormagnesite powder, water glass and zeolite particles in the adhesive are different, see Table 2 for details.

[0041] Table 2 Preparation Example 1-3 The detailed list of the addition amount of each component

[0042]

[0043]

preparation example 4

[0045] The difference from Preparation Example 3 is that when the boronite powder, water glass and zeolite particles are mixed, the temperature is raised to 100°C, and after mixing evenly, the mixture is kept at a temperature of 110±5°C for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com