Recyclable prefabricated composite soil nail wall support structure system based on anchor cables and soil nails

A support structure and composite soil nailing technology, which is applied in infrastructure engineering, construction, excavation, etc., can solve the problems of underground space development obstacles, waste of building materials, geological environment pollution, etc., and achieve resource saving, construction cost saving, and resource saving. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

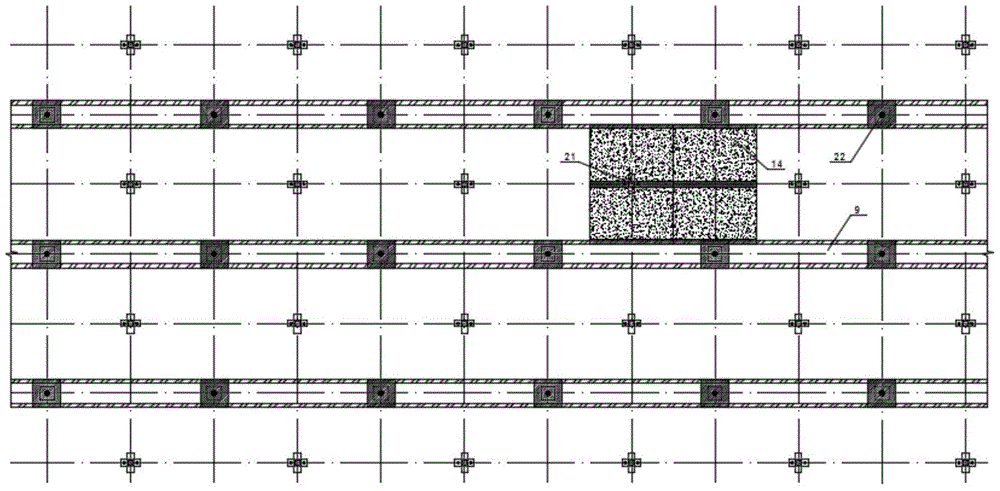

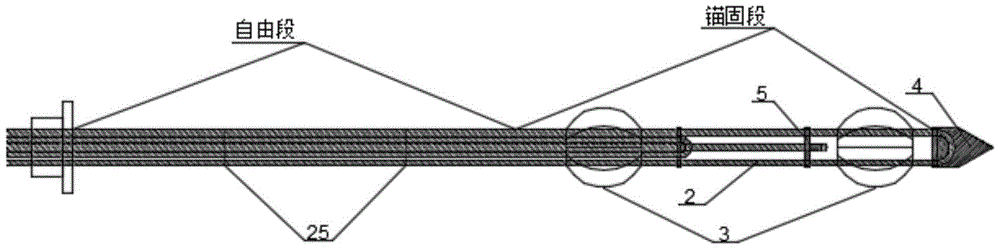

[0038] figure 1 Shown is a schematic diagram of the installation of the prefabricated recyclable composite soil nail wall support structure based on anchor cables and soil nails. The installation sequence is to make recyclable anchor cables first, clean up the slope, and then set the first row of soil nail nodes according to construction requirements 8 Then lay the node 8, drill one end of the soil nail 1 through the node 8 into the slope, and the end left on the slope is fixed with the soil nail anchor head 21, and the soil nail end node 22 is formed here; Then set the waist beam 9 in the second row, reserve anchor cable holes with a certain interval on the waist beam 9, determine the drilling position on the slope according to the anchor cable hole, then unload the waist beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com