A structure integrating anti-seepage membrane anchoring, flood interception and traffic

An anti-seepage membrane and anchoring technology, which is applied in the field of staged construction structures, can solve the problems that the roof anchorage platform and anchoring ditch are difficult to form regularly, the construction quality is difficult to be guaranteed, and the slope is easily washed by rainwater, etc., so as to facilitate the organization of flow operations , Strengthen the effect of protection and anchoring effect, enhance the effect of anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

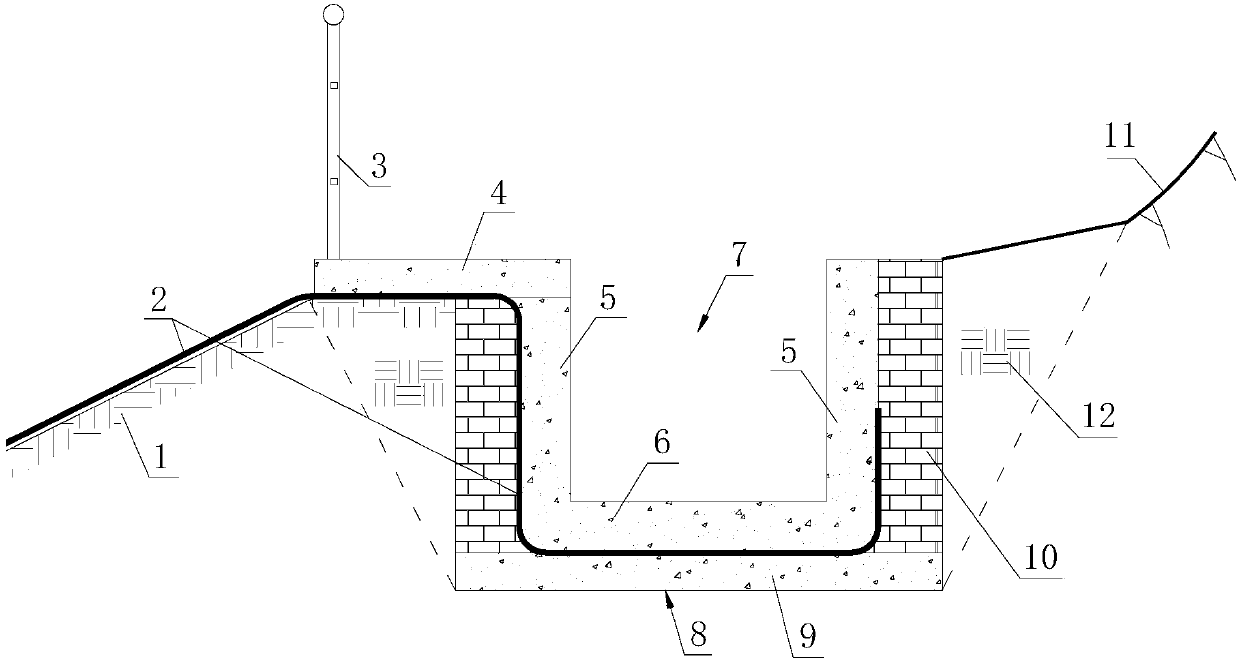

[0029] Such as figure 1 As shown, the required anchoring ditch 8 is first excavated according to the design requirements. The anchoring ditch 8 adopts a rectangular cross-section. The size of the anchoring ditch 8 meets the size requirements of the design, and at the same time meets the size requirements of the flood intercepting ditch 7, and the excavation surface is smooth. Adopt concrete to carry out the pouring of anchor ditch bottom plate 9 at the bottom of anchor ditch 8, after treating, adopt brickwork, stone masonry or concrete pouring anchor ditch ditch wall 10 on both sides of anchor ditch bottom plate 9, its yin and yang corners are made arc-shaped. Treat the side slope 1 of the reservoir area according to the design requirements, and at the same time compact the backfill soil 12 on both sides of the anchor ditch 8, and then lay and temporarily fix the anti-seepage membrane on the side slope 1 of the reservoir area, the bottom plate of the anchor ditch 9 and the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com