Combined reinforcing rib structure

A technology for strengthening structures and reinforcing ribs, which is applied in construction, large-capacity bulk material storage, building types, etc., and can solve the restrictions on the application and promotion of PP plastic pools, the structural strength cannot be guaranteed, and the sealing performance cannot be guaranteed, etc. problems, to achieve the effect of solving insufficient structural strength, shortening the construction period, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

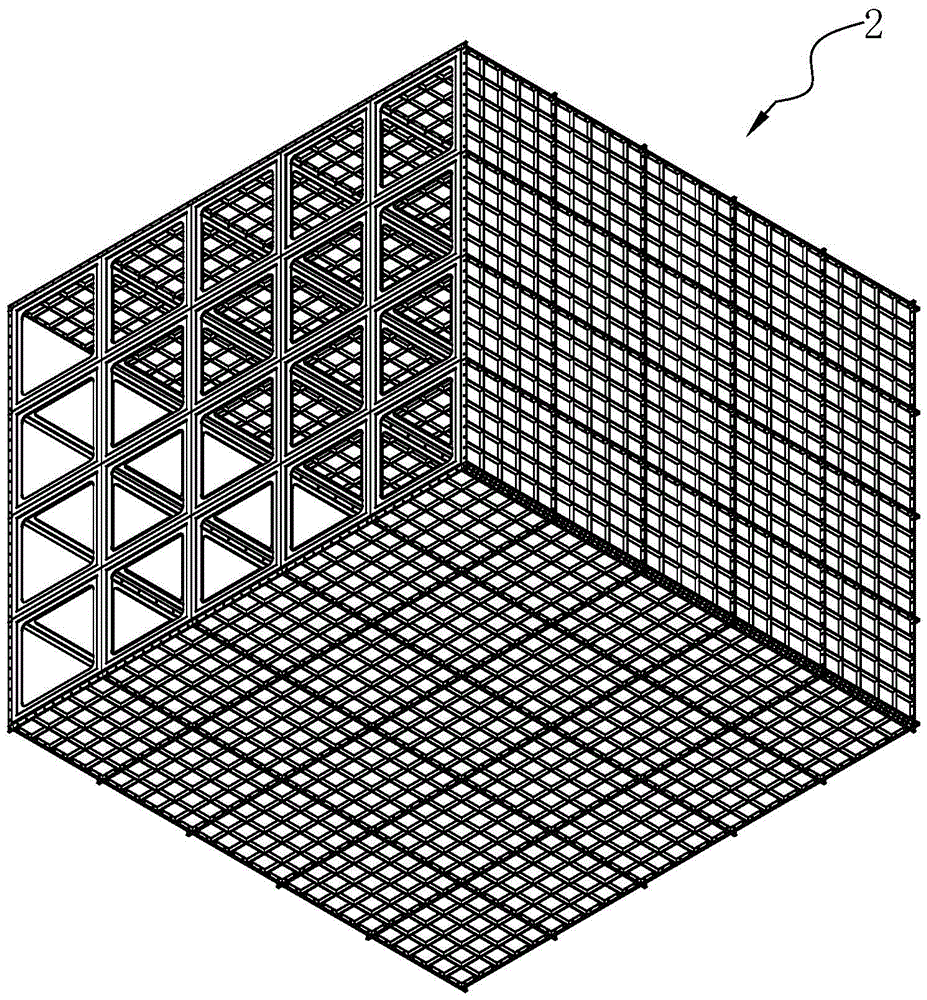

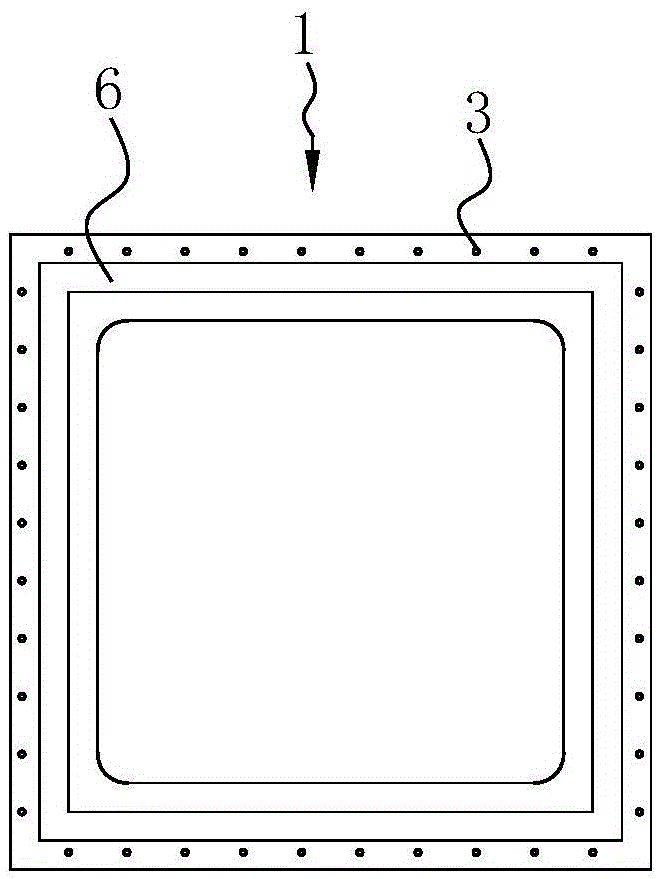

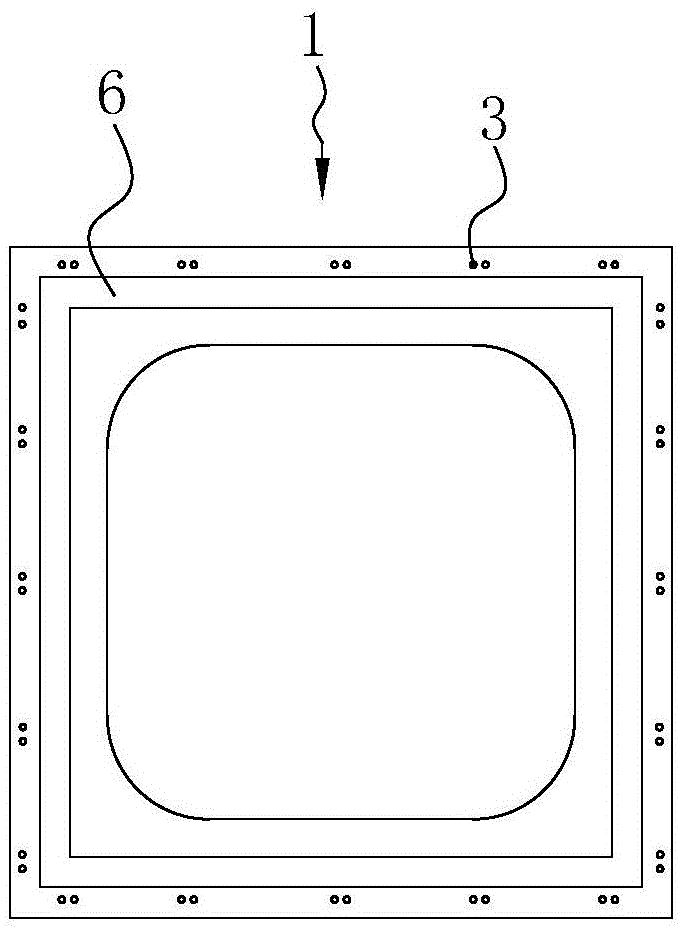

[0032] combine Figure 1-16 A combined reinforcing rib structure shown includes a plastic combined box 2 for containing liquid, and inside the box 2, a plurality of such as Figure 4 The mesh reinforcement structure shown. The mesh reinforcement structure is generally made of plastic, and can be directly injection molded into a mesh shape. It is also possible to heat-bond a plurality of strip-shaped reinforcing ribs in a frame to form a mesh. The reticular reinforcement structure is criss-crossed to form a reinforcement frame, that is to say, the reticular reinforcement structure can be regarded as a plane, and the reinforcement frame is formed by interlacing multiple planes such as figure 1 The three-dimensional support structure located inside the box body 2 is shown. The shape and size of the reinforcing frame match the shape and size of the box body 2 . The reinforcing frame is arranged inside the box body 2, and can support different regions of the box body 2. If the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com