Backfill construction method of pilot tunnel vault in double-arch tunnel

A construction method and double-arch technology, which can be used in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as inability to perform at the same time, and achieve the effect of shortening the effective working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

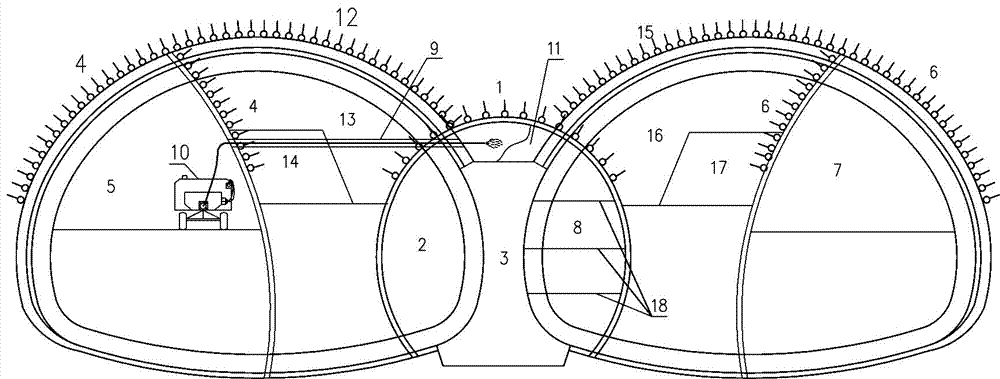

[0039] Such as figure 1 As shown in , a method for backfilling the pilot tunnel vault in a double-arch tunnel includes the following steps:

[0040] 1. Advanced support for the middle pilot tunnel 1;

[0041] 2. Intermediate pilot tunnel excavation and initial support 2;

[0042] 3. Binding steel bars of the middle partition wall and placing the trolley in place, and then pouring concrete for the middle partition wall 3; in the preferred scheme, after the middle pilot tunnel is excavated to a certain depth or penetrated, the tunnel is constructed from the inside of the central pilot tunnel or the penetration point to one end Or pour the middle partition wall at both ends of the entrance and exit.

[0043] The time and location of the pouring of the partition wall shall be determined according to the latest start time of excavation and support of the steps on the left pilot tunnel or the right pilot tunnel.

[0044] After the concrete pouring of the partition wall is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com