Variable valve timing device

A valve timing and variable technology, used in valve devices, engine components, machines/engines, etc., can solve the problems of high cost, difficult processing, low efficiency, etc., and achieve low processing costs, easy finished products, and wear-resistant Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

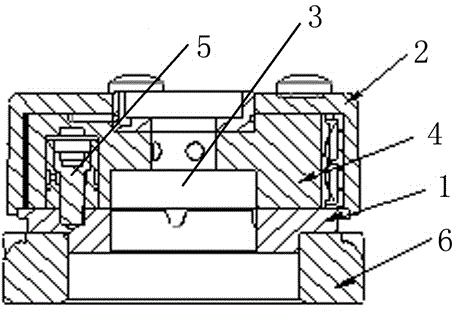

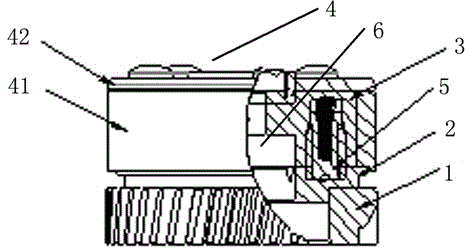

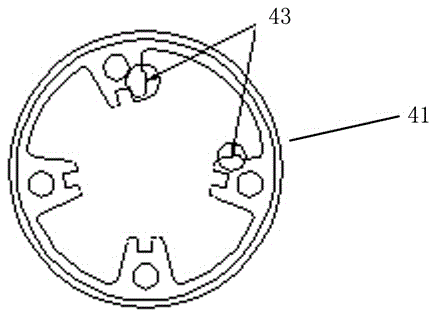

[0024] Such as Figure 2 to Figure 5 As shown, a variable valve timing device of the present invention includes a helical gear 1, a gear insert 2, a rotor 3 and an outer cover 4. The helical gear 1 is connected with the outer cover 4 through a gear insert 2, and the gear insert 2 and the outer cover 4. A hydraulic chamber is formed. In the hydraulic chamber, there is a rotor 3 connected to the gear insert 2 through a locking device 5. The middle part of the rotor 3 is connected to the camshaft 6. The locking device 5 includes a locking pin 51 and a locking pin hole 52. The locking pin 51 is placed on the lower surface of the rotor 3 , the upper surface of the gear insert 2 is provided with a locking pin hole 52 matching the locking pin 51 , and the bottom of the locking pin 51 is provided with an oil storage tank 53 . There is an oil storage tank 53 at the bottom of the locking pin 51, and a certain amount of lubricating oil is retained in the oil storage tank 53 of the lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com